Placing small objects on build plate

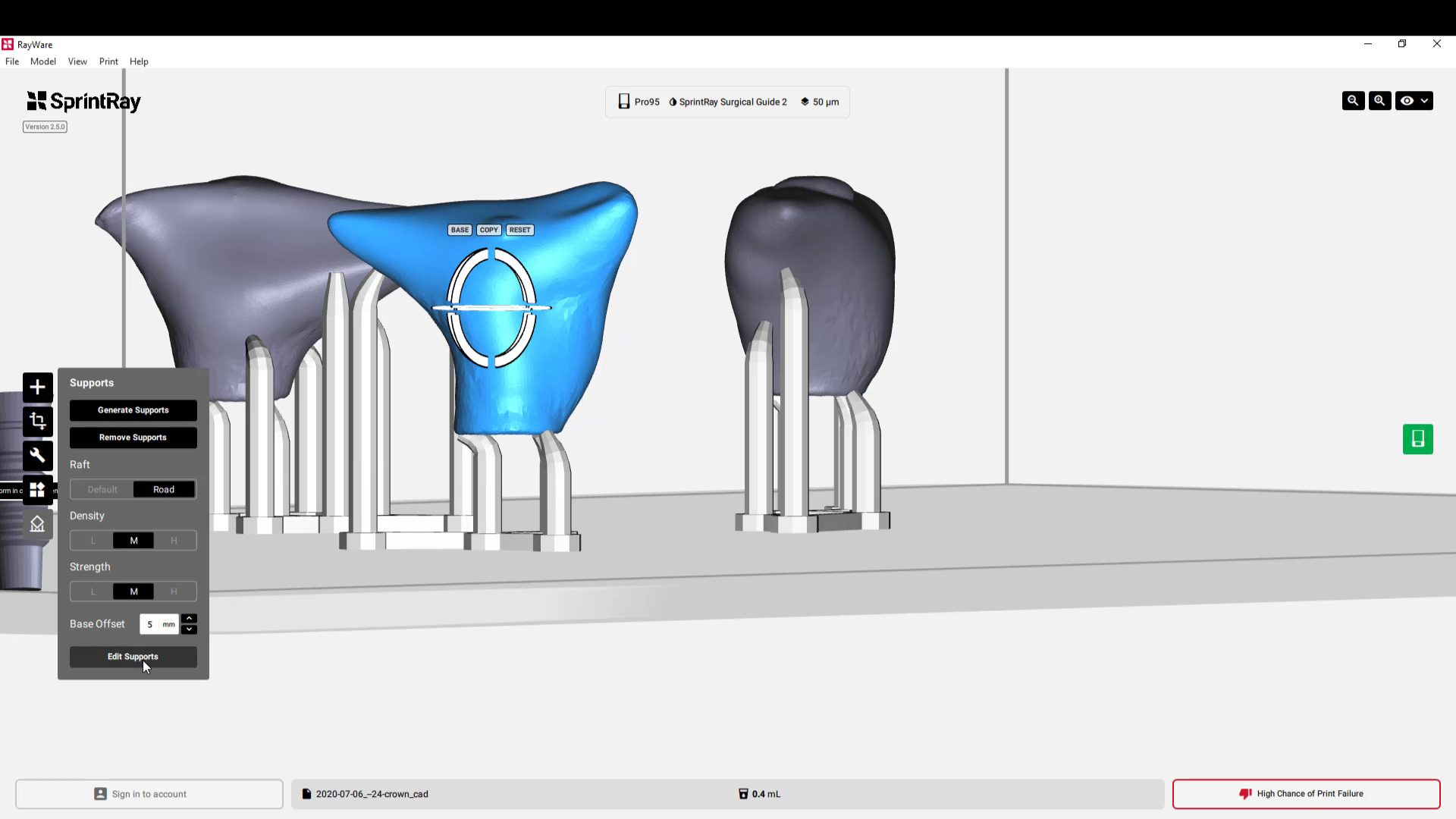

When printing it is important to select a “Base Offset.” This function will use supports to raise the model off of the plate. This function should be used when the base of the model is not flat on the plate. An offset between 1-3mm is recommended but it is up to the user to decide. Once the offset is set, select “Generate Supports.” The purpose of offsetting the model is to overcome the compression layer. The compression layer spans the first few layers of printing. The offset can also help with the drainage of resin if there is a hole in the model, preventing this compression.

Selecting the “Fix” function on the model itself will automatically generate supports but will not take into account the settings placed in the “Supports” tool bar. To place supports that follow the guidelines that the user sets, select “Generate Supports.” The supports can be edited using “Edit Supports.” Just a reminder, if one support is removed, another is recommended to be added nearby. Supports are essential near the bottom of models to ensure there is no distortion. To ease with the editing of supports, the plate is transparent on the program so users can look at the models from the underside. It may take a few trials to discover where the supports are the most effective for the model printed.

If a hole is perfectly vertical, it can form pressure during printing, distorting the object. It is recommended to place models with holes at an angle to prevent this from occurring. Make sure to check the supports generated from the “Fix” to ensure that the models being printed are properly supported to prevent distortion. The “Fix” button can generate supports that may not be wanted. If this is the case, select “Edit Supports” to place supports where needed. Selecting “Generate Supports” will also make these changes automatically.