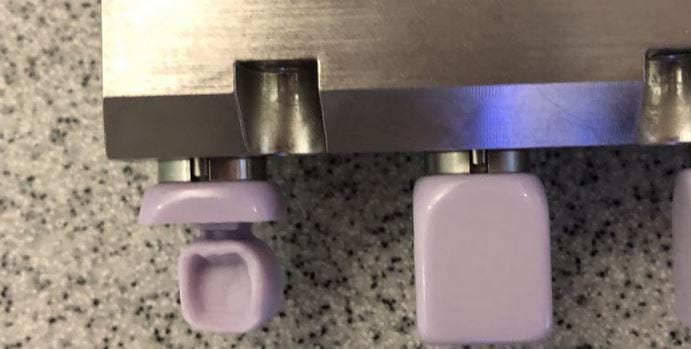

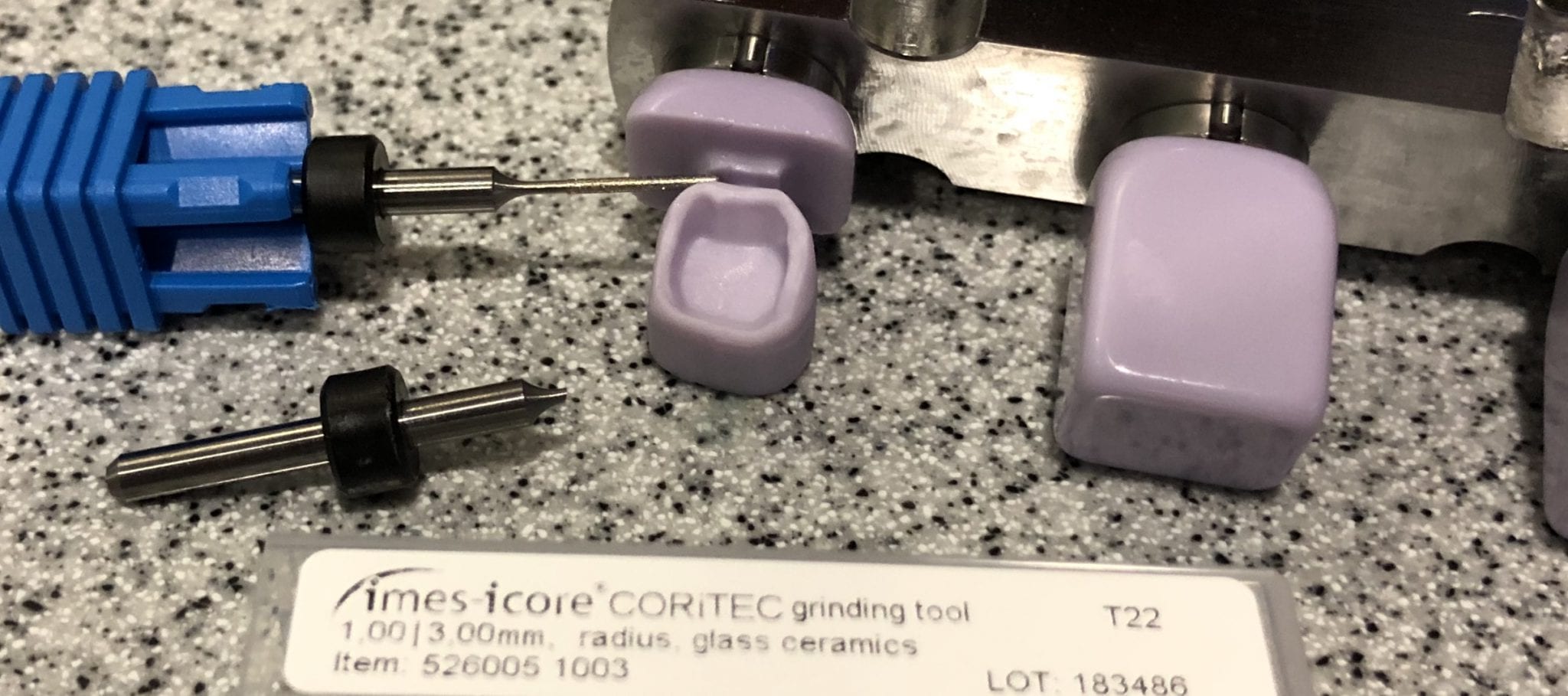

A drill fractured upon just minutes of use! If you look at the distance between the restoration and the remaining wall of emax material, you can see how that lack of clearance can wedge the drill into that space. This can lead to drill breakage and/or the block breaking off the holder! This can be very frustrating for chairside and same visit dentistry

In this image, we demonstrate how difficult in can be for the 1 mm drill to access the area of the sprue. Your options are to increase that space or build a sprue that can give you much better access and not be pinned into that area.

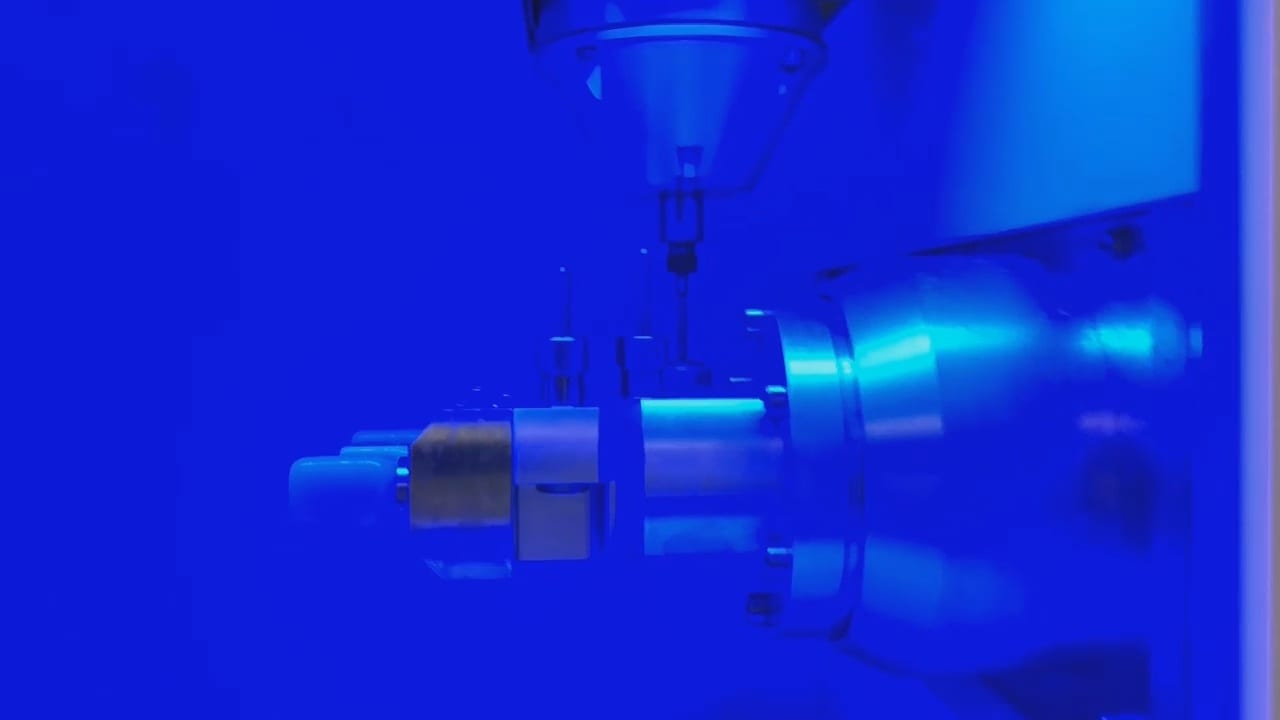

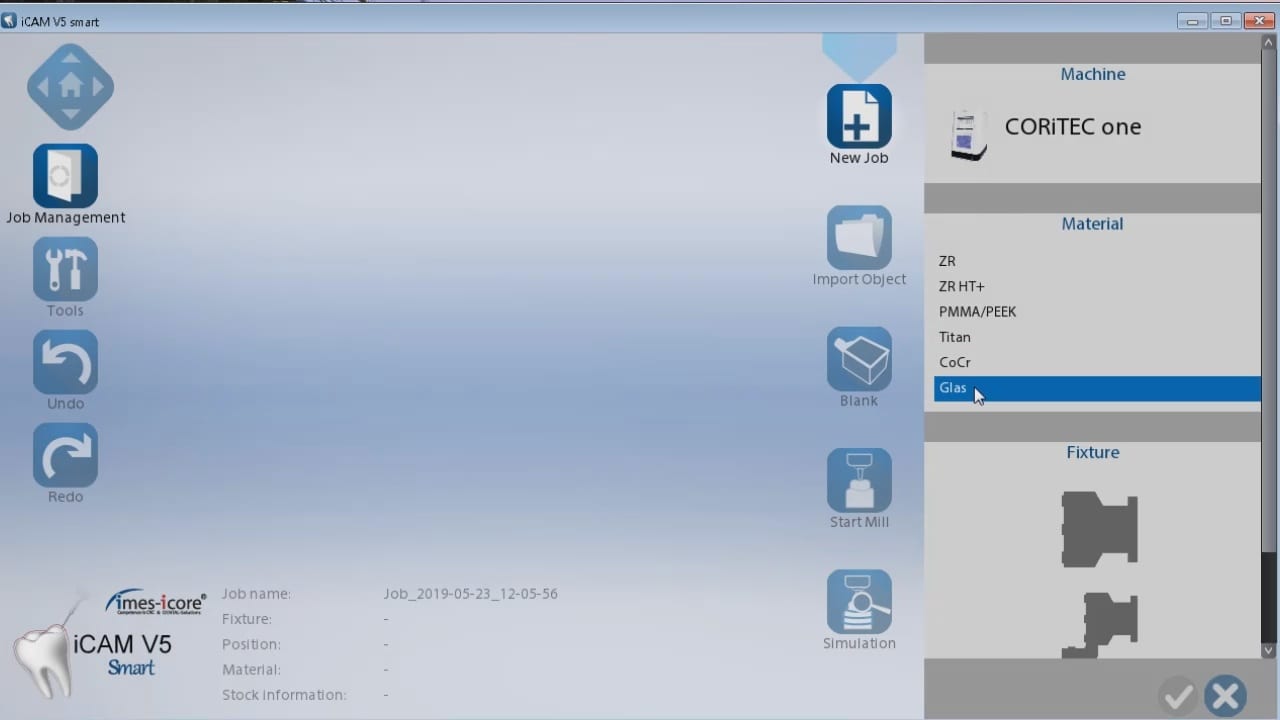

In this video, we do the autopsy of the case. There is a perimeter around the restoration that you can control, which has a setting of 1, 2, or 3. The smaller the distance and clearance from the restoration, the less wear and tear you place on your drills. On the other hand, that same distance can lead to limited access and breakage of the drills.

In this video, you can see us trying to balance the sprue location and size taking many factors into consideration. First we must design a case multiple ways and assess the mill times that the CAM software calculates. We then tabulate those parameters and take other things into consideration, like the amount of time it takes to mill a restoration.

Unfortunately, we have to consistently mill and fabricate multiple “burner blocks” to see the cause and effect of our settings. As a clinician to clinician business model, we strive to provide you with a lot more than the conventional manufacturer and distributor does; we test processes well beyond simple rubber stamped “validated process” and we absorb the cost of the machinary and blocks so that you don’t waste time and money to learn all this the hard way.

You must be logged in to post a comment.