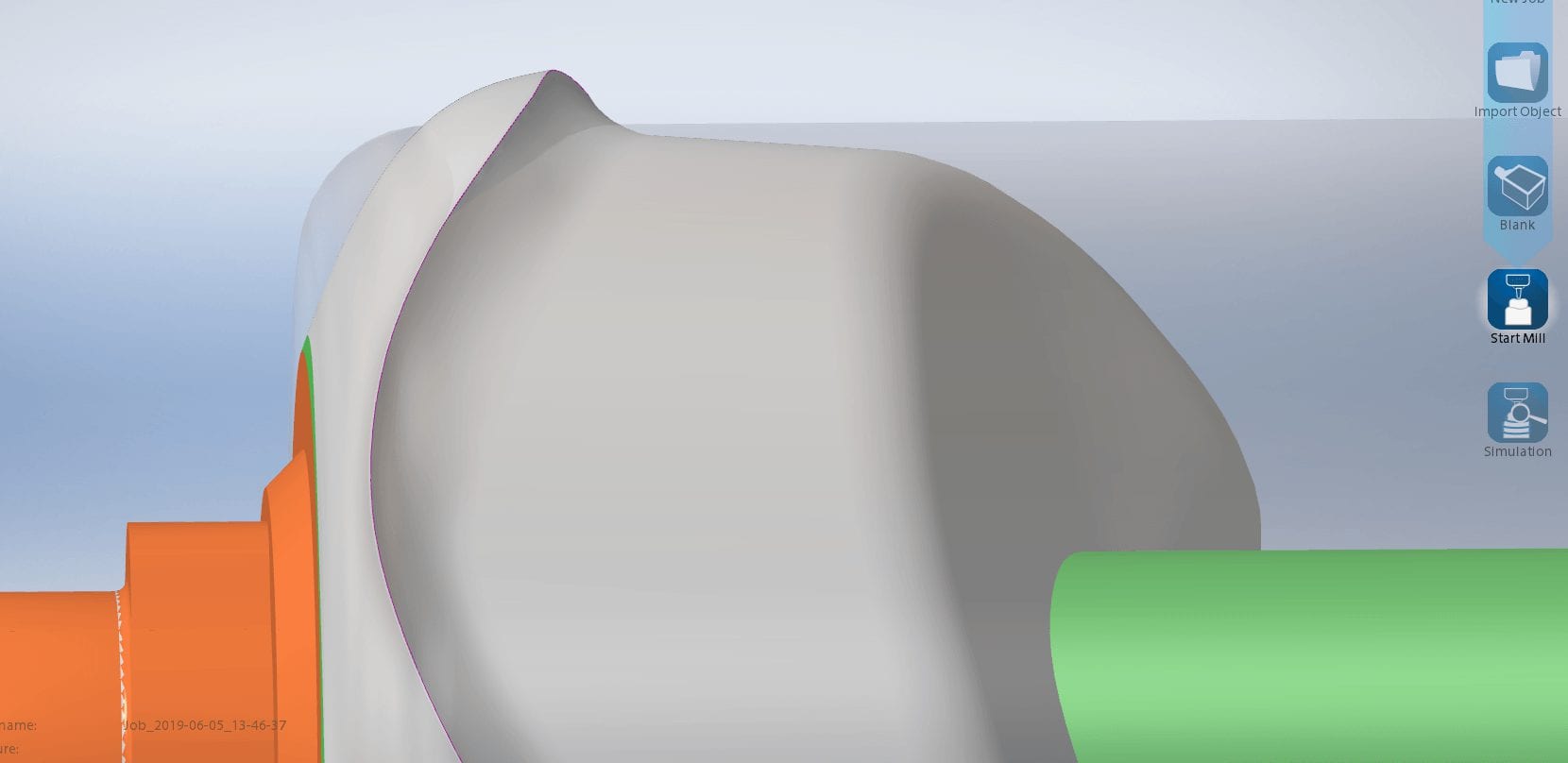

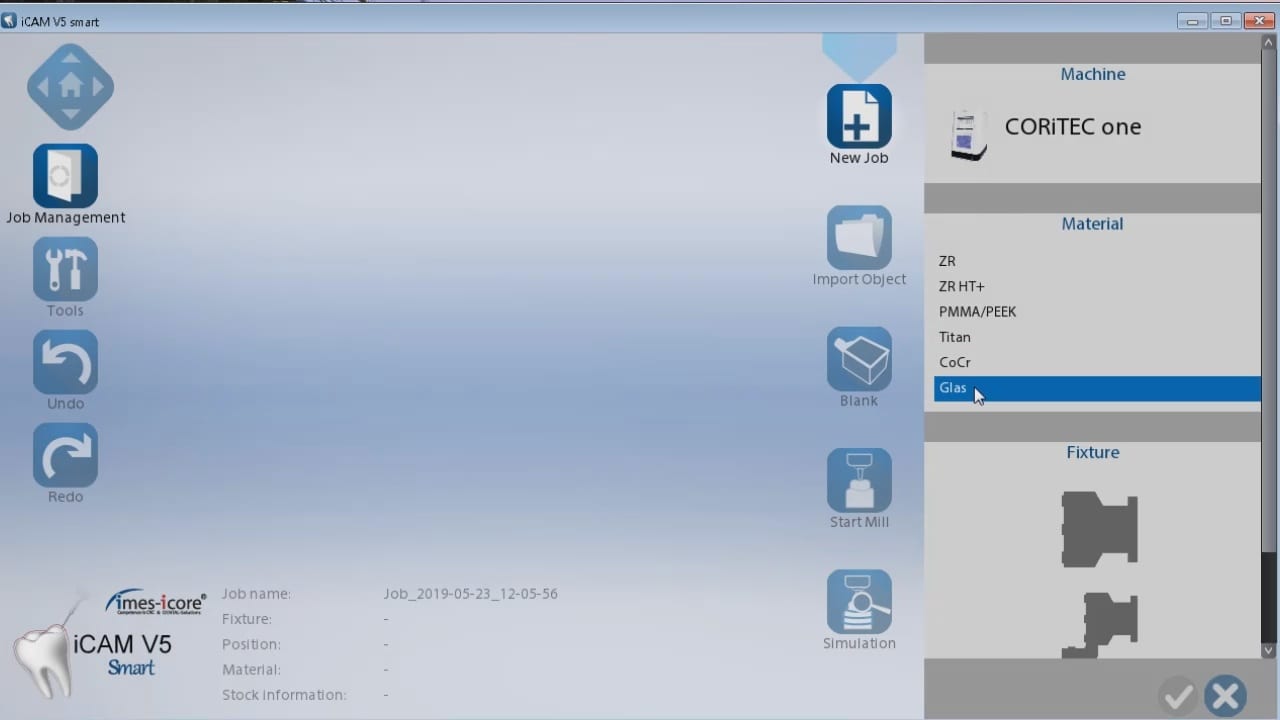

One important feature to keep track of during an abutment design and mill are the boundaries / diameter of the pre-mill blanks. As a new user, it is easy to select the wrong scanbody or introduce a dozen errors that can impact the final product. As of June 2019, you have two choices with the DESS blanks, a 10 or 14 size diameter. The size 14 obviously will take longer to mill and put more wear and tear on your machine and the drills

With the size 10 block, you run the risk of being outside the perimeter of the cylinder shape. It is up to you to keep track of these potential errors and boundaries. In this particular case, it took us hours to figure out why the machine stopped milling. The software essentially stalled and stopped working because our design was outside the boundaries of the design

You must be logged in to post a comment.