Today, clinicians and lab technicians are leveraging technologies to produce better results and run a better business now more than ever.

So how does this work? Why should you care?

First we need to define the differences. What is a digital workflow?

A digital workflow is the process of using advanced technology and 3D precision without analog materials or human error to deliver patient care.

The reason clinicians or technicians should commit to mastering digital workflows is because it will lean out their production helping them avoid slow and costly processes.

Take for example a basic full coverage crown procedure. During the conventional process the clinician will start by taking an impression of the patient using polyvinyl materials. After the materials set and it’s determined there are no errors chairside, they will ship the impression to the lab which can take a few days depending on location. When the impression finally reaches the lab, a technician will pour up the impression in stone to produce a model and determine accuracy. After this time consuming process is completed, the technicians enter the manufacturing phase.

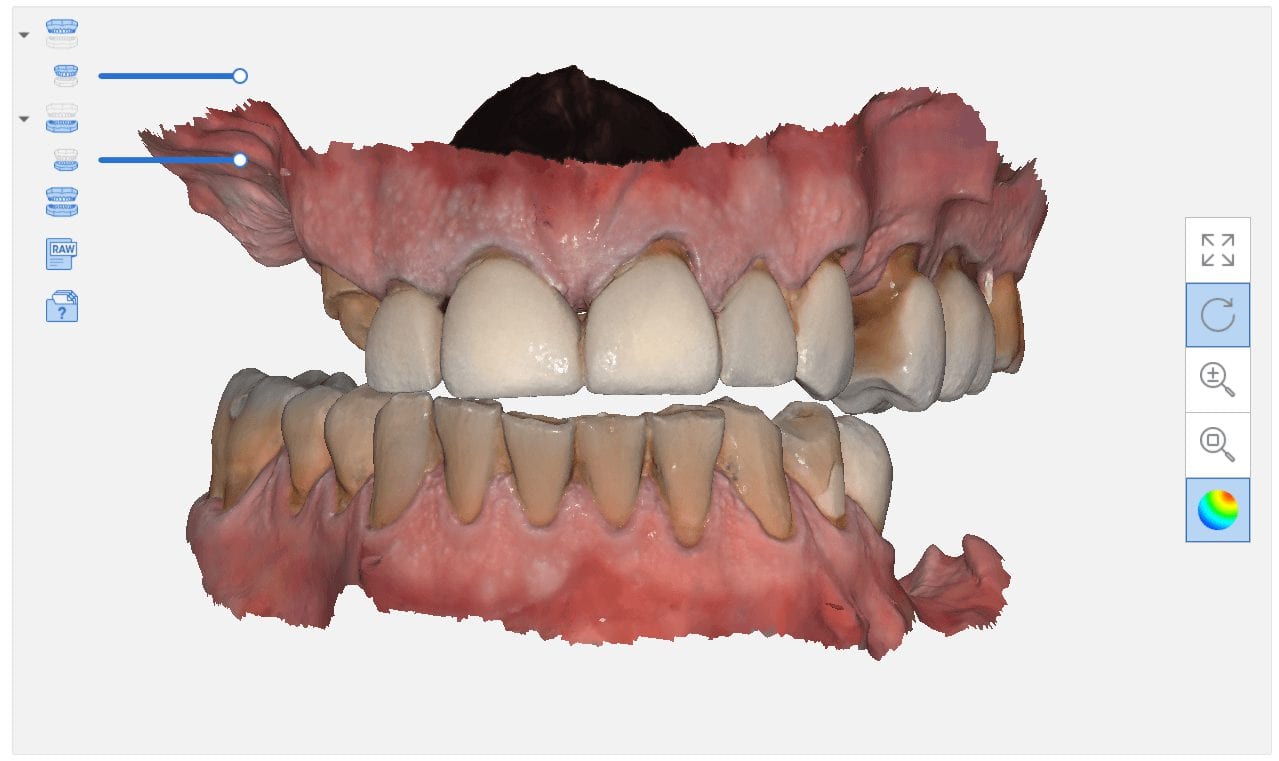

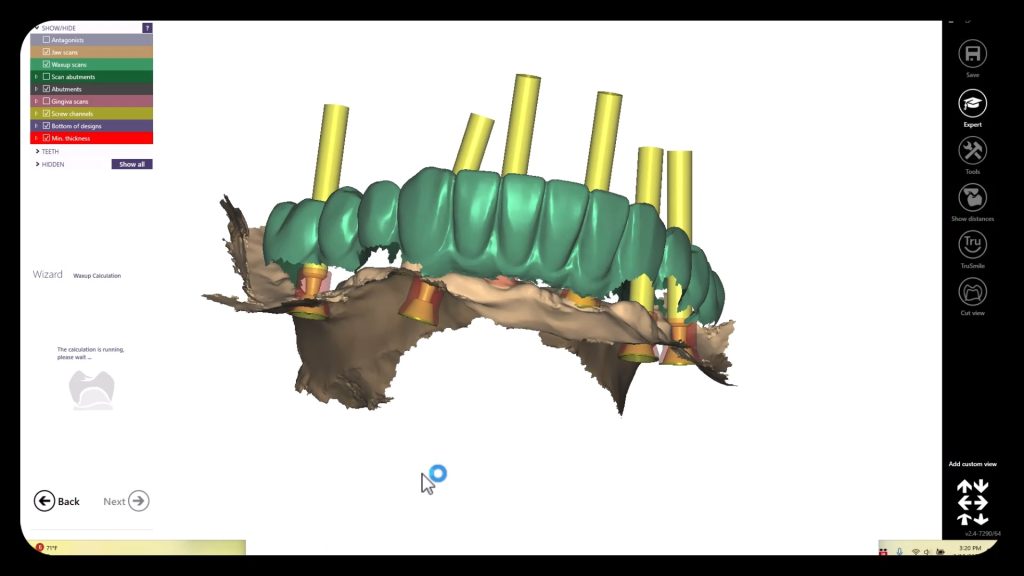

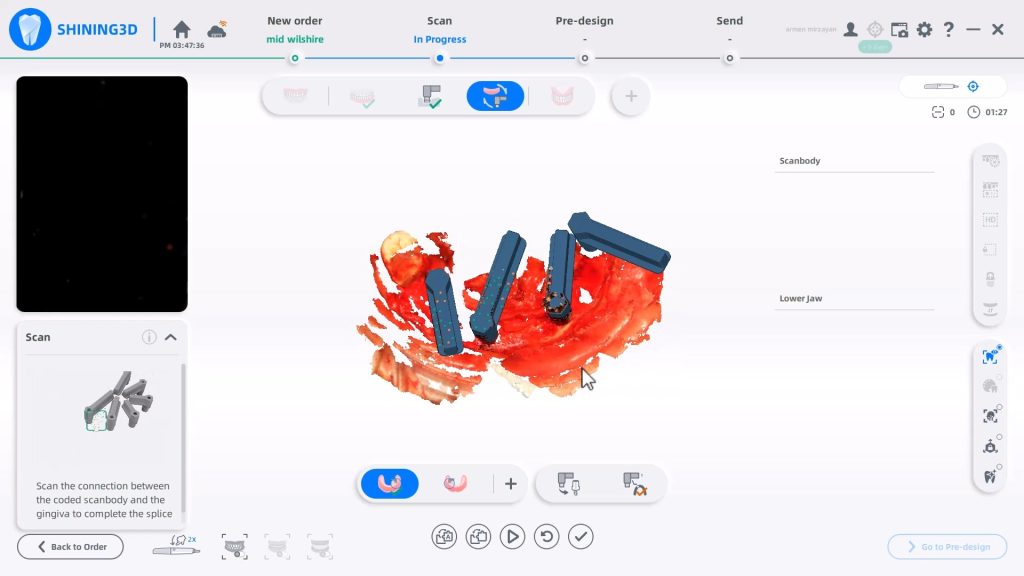

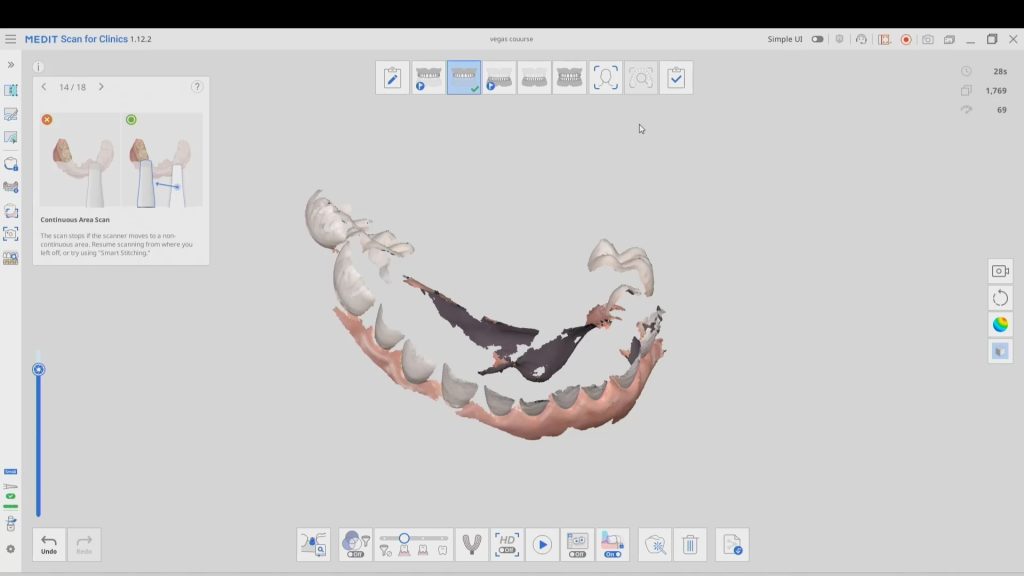

For comparison, if the clinician and lab practiced with a digital workflow, they would have the ability to cut out each of these steps therefore delivering superior accuracy. The clinician could use a device such as an intraoral scanner to digitally capture a 3D model of the patient and instantly deliver the model to the lab using electronic file exchange. The lab would download the file and immediately begin digitally designing the proposal before milling or 3D printing final prosthesis. Practicing with this process eliminates the costs and headaches of analog materials that can introduce errors and delays.

Digital workflows are very simple to learn. They make life so much easier once you understand.

In summary, any practice owner or lab owner can keep their production lean by introducing digital workflows to eliminate costs, time, and errors.

You must log in to post a comment.