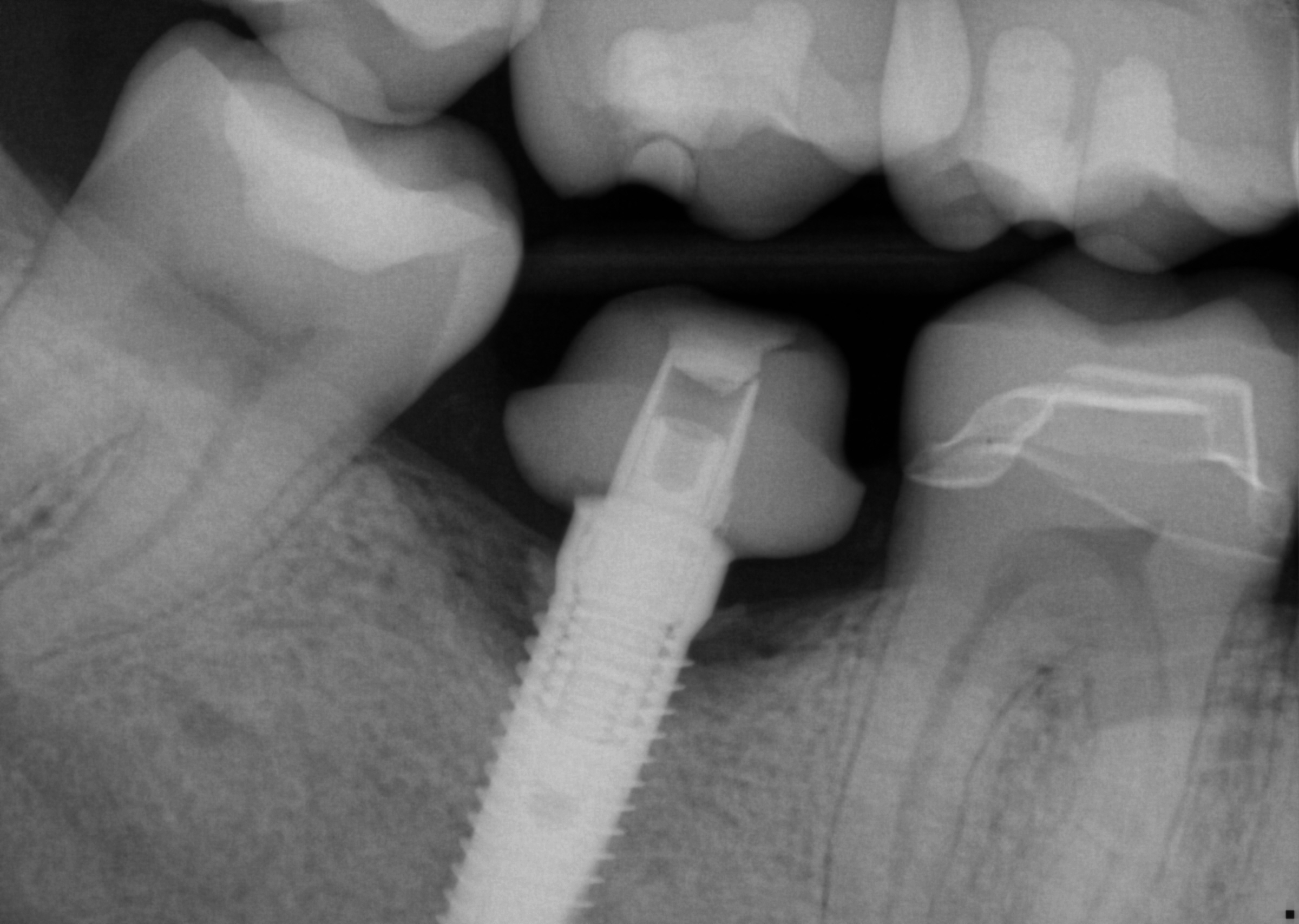

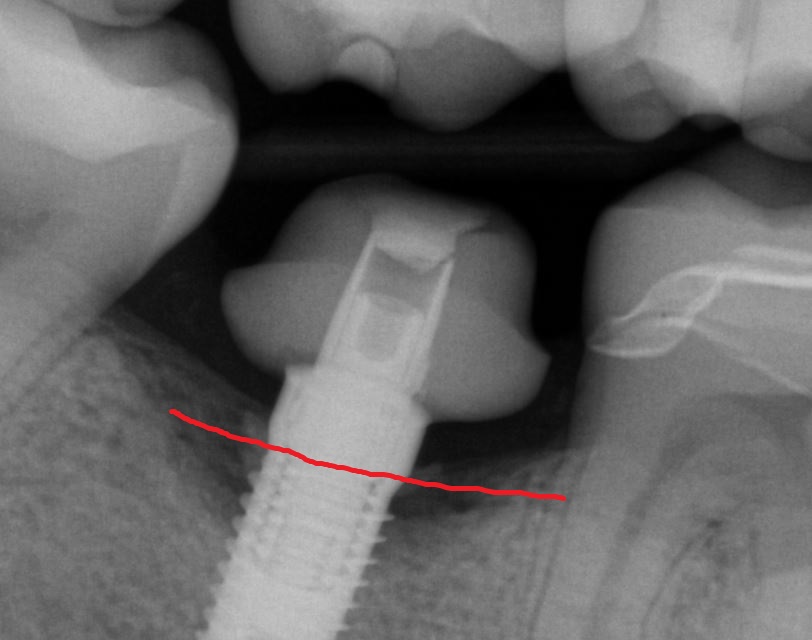

This implant was initially placed at the crest of the ridge in 2012. its placement did not allow proper emergence profile and subsequently lost bone around the head of the implant by 2015. The lack of blood flow to the crest of the bone at the cortical plate certainly could have contributed to its demise. By 2015, the bacteria trap forced a new restoration to be placed which also ultimately lead to chronic inflammation due to improper contours. The implant itself was well integrated and the decision was made to remove the top 3-5 mm of the implant and treat it as a cast post and core.

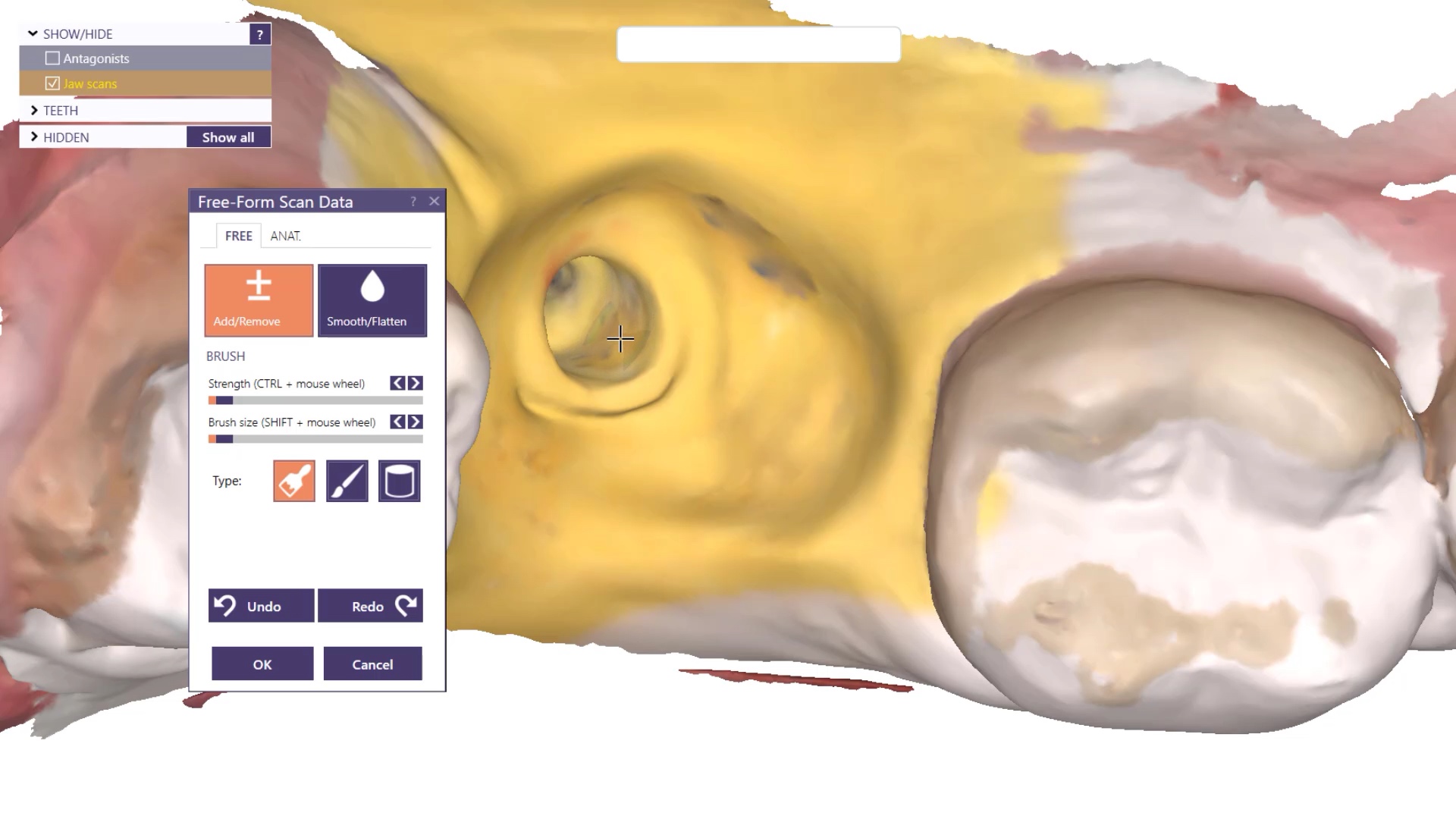

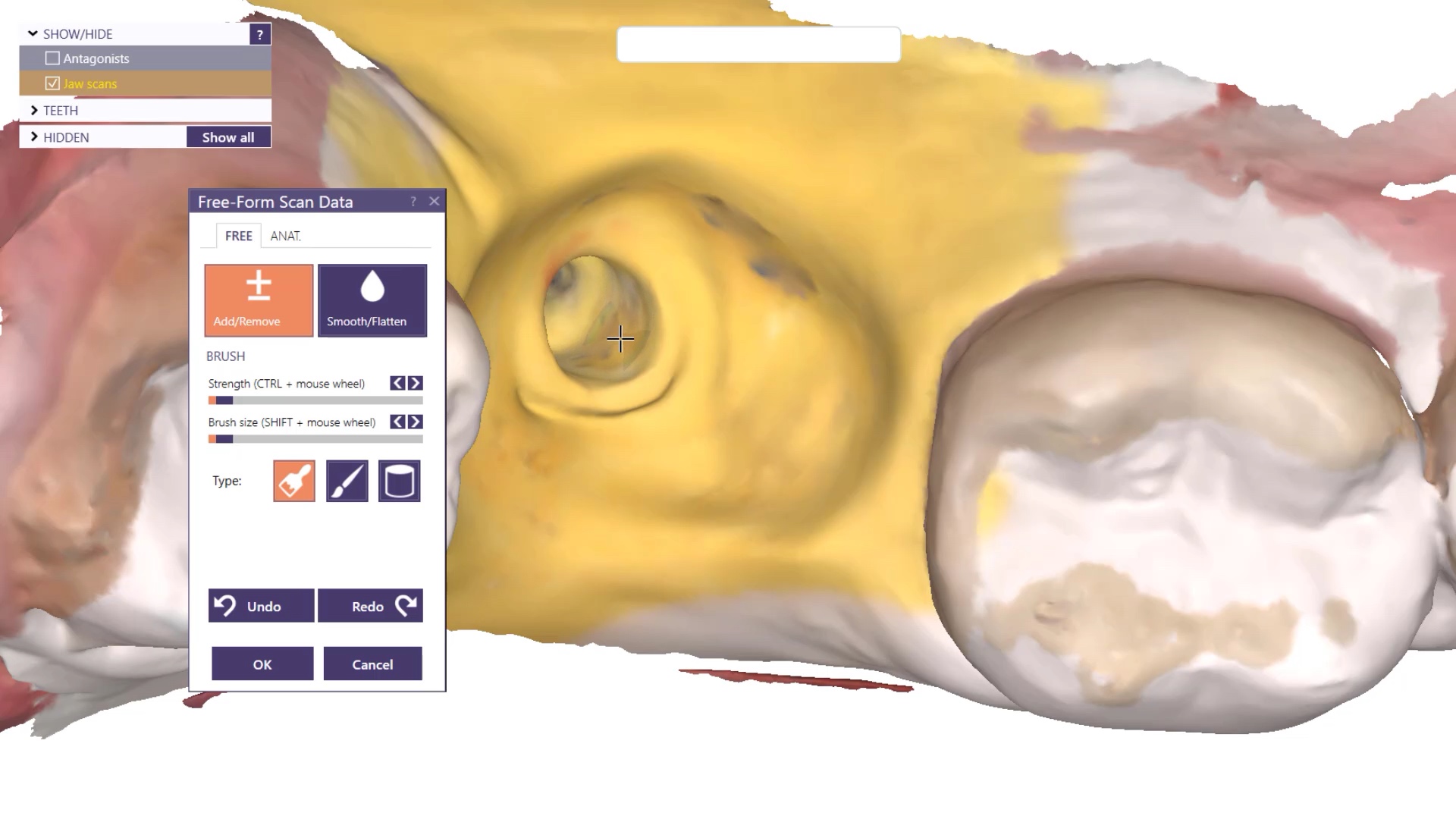

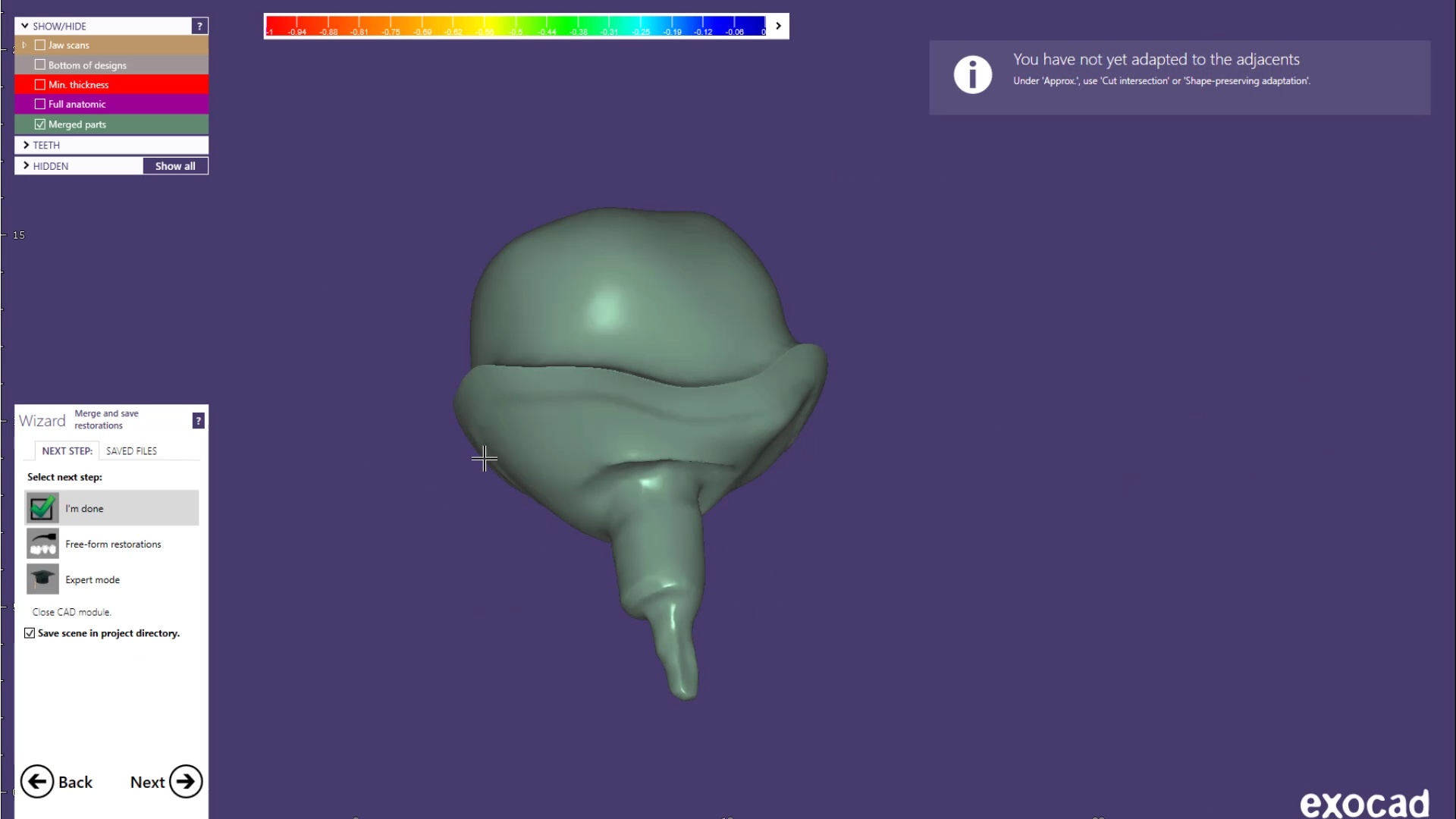

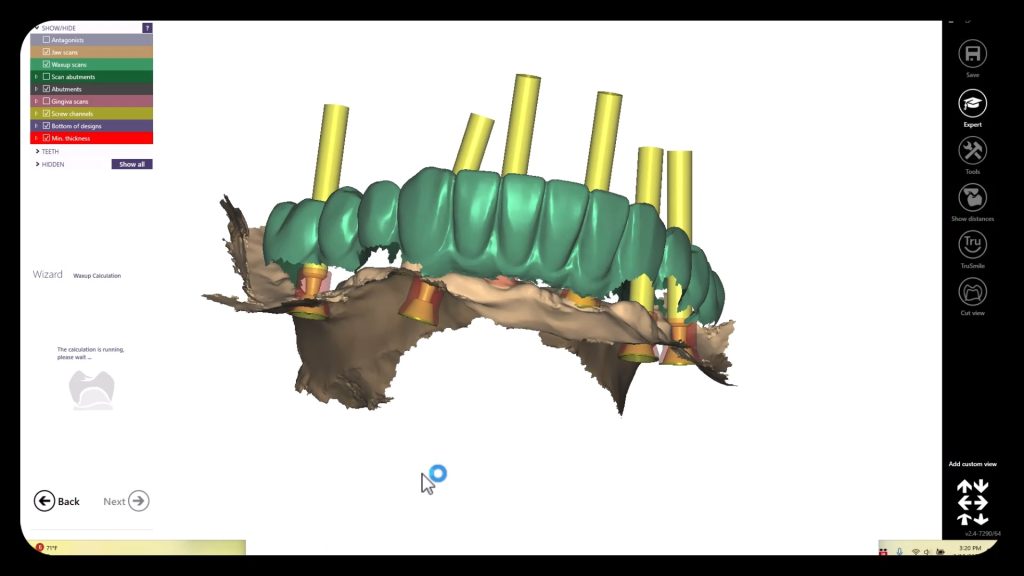

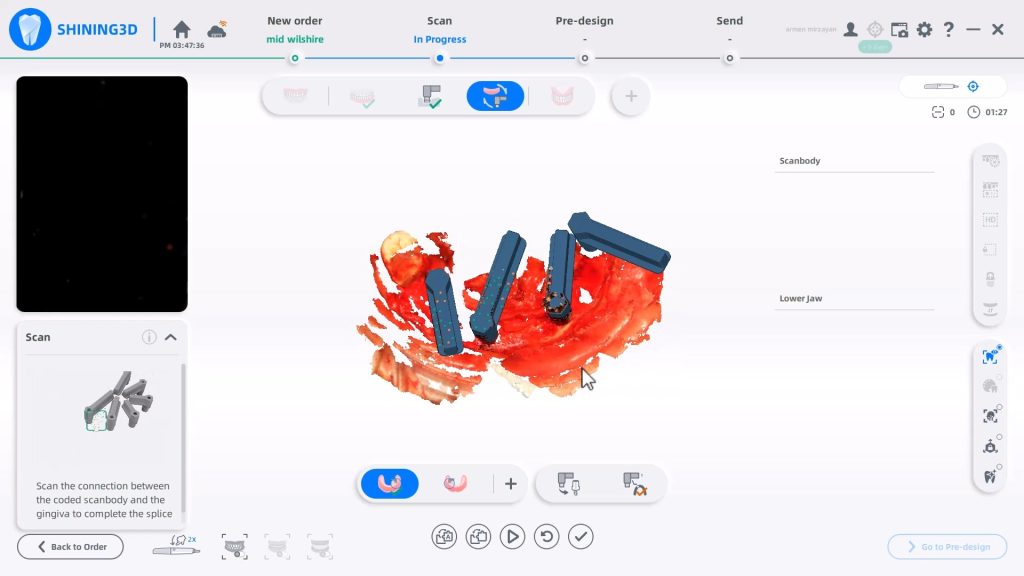

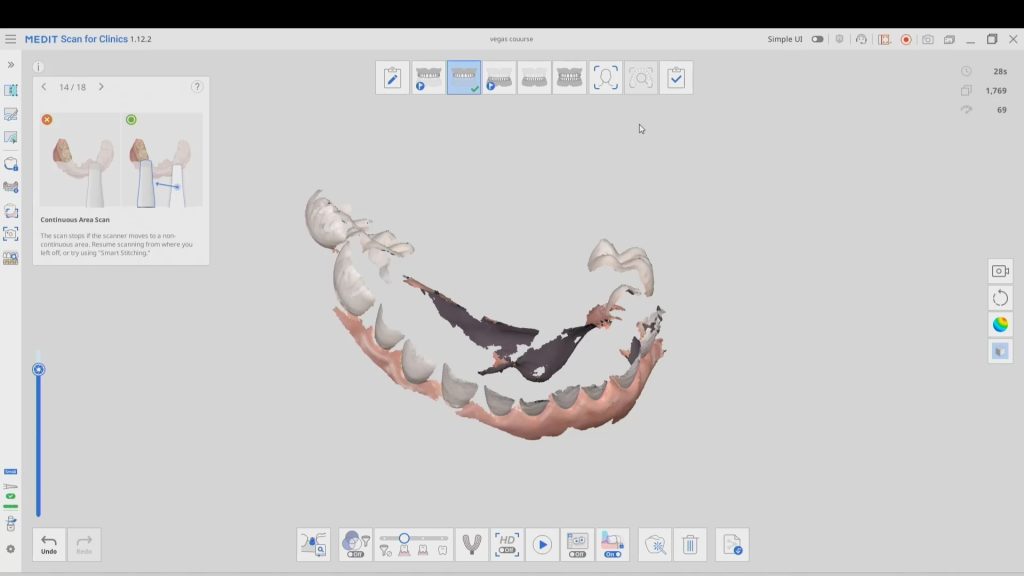

You can see how the Medit i700 was used to mix intra-oral scans with a PVS impression to capture the fixture. Advanced users can utilize the stl of the implant itself to fabricate a post and core digitally.

The designed restoration was then sent to Burbank Dental Lab and it was milled out of wax and then cast to metal

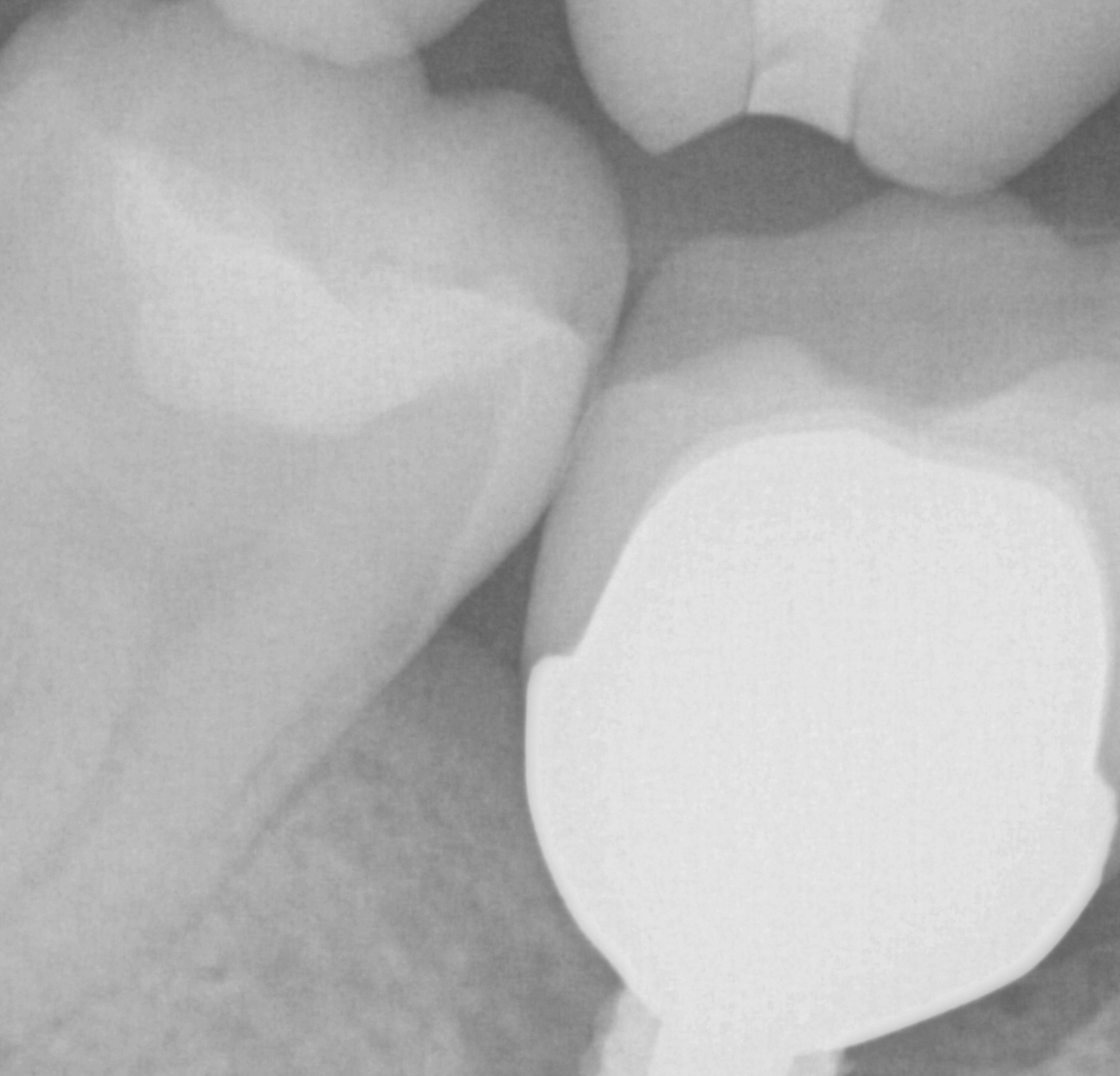

The post and core and the emax restoration were returned for delivery. The emax was not crystalized until after the abutment was cemented and then it was tried in by itself to assure proper contours and contacts. The great feature of lithium dissilicate is that you can add contact and glaze at the same time, which was required here as the mesial contact was weaker than desired after some minor adjustments

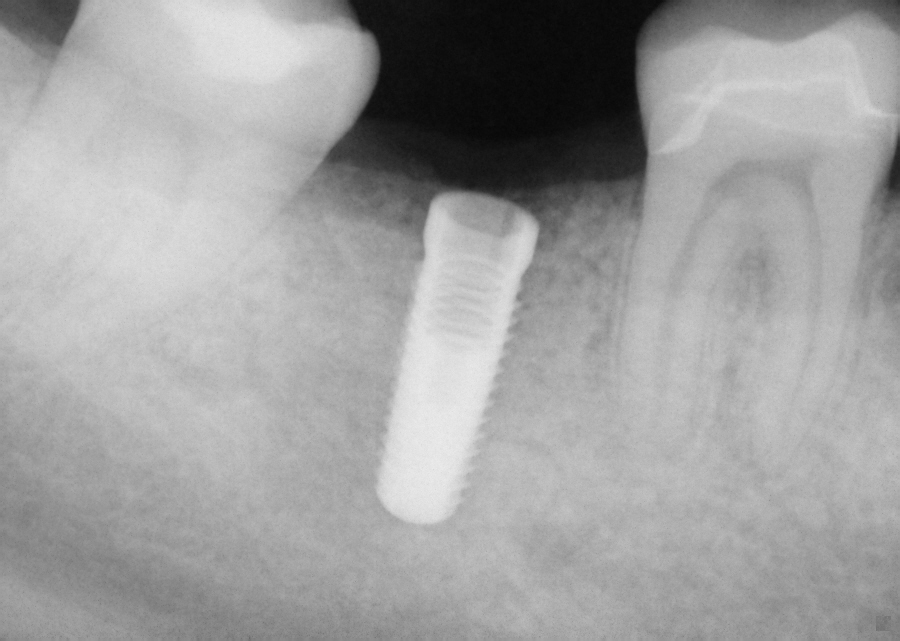

Post op x-rays to verify seat and no excess resin after flap was raised to clinically visualize that there is no excess cement

You must log in to post a comment.