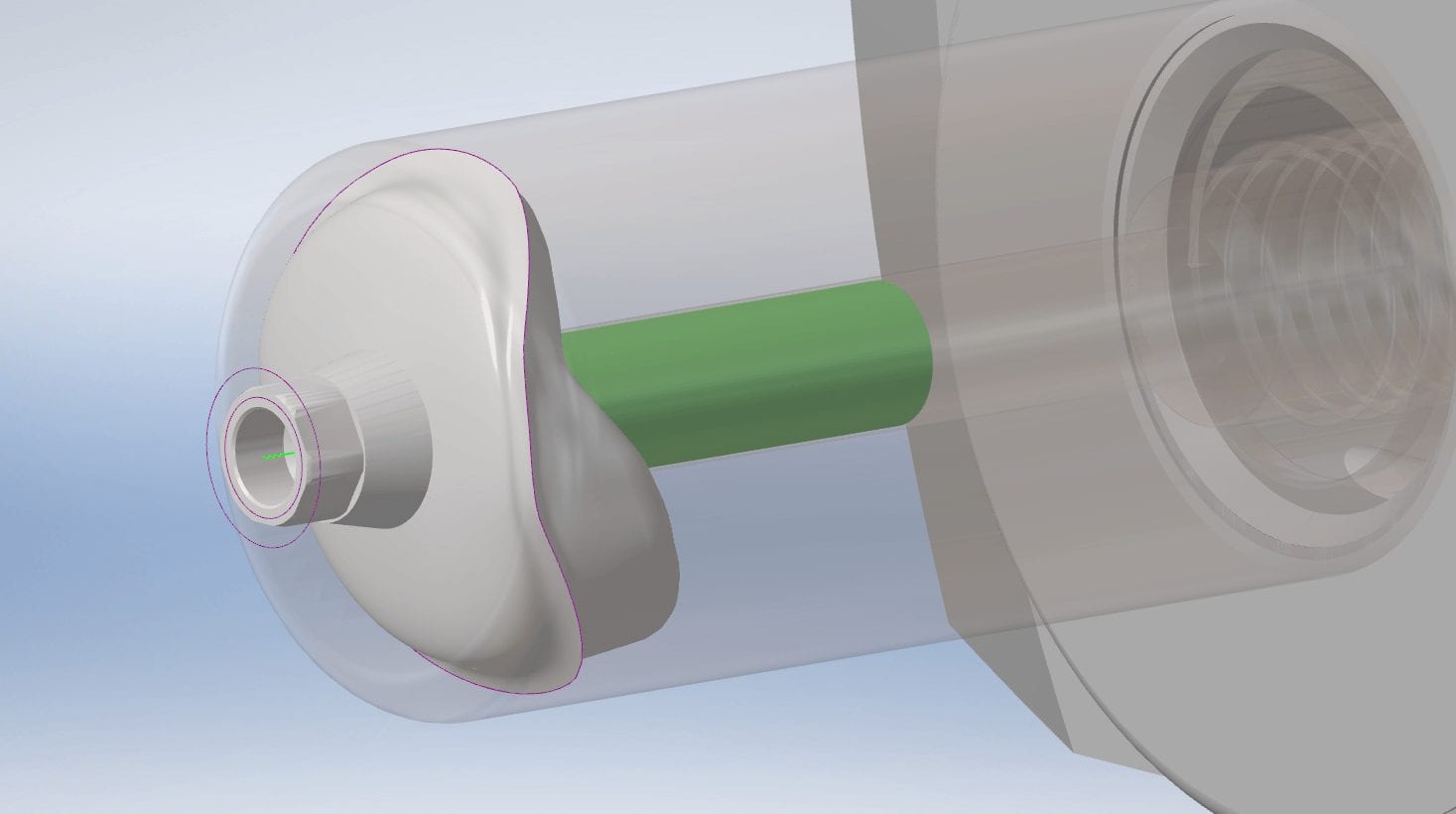

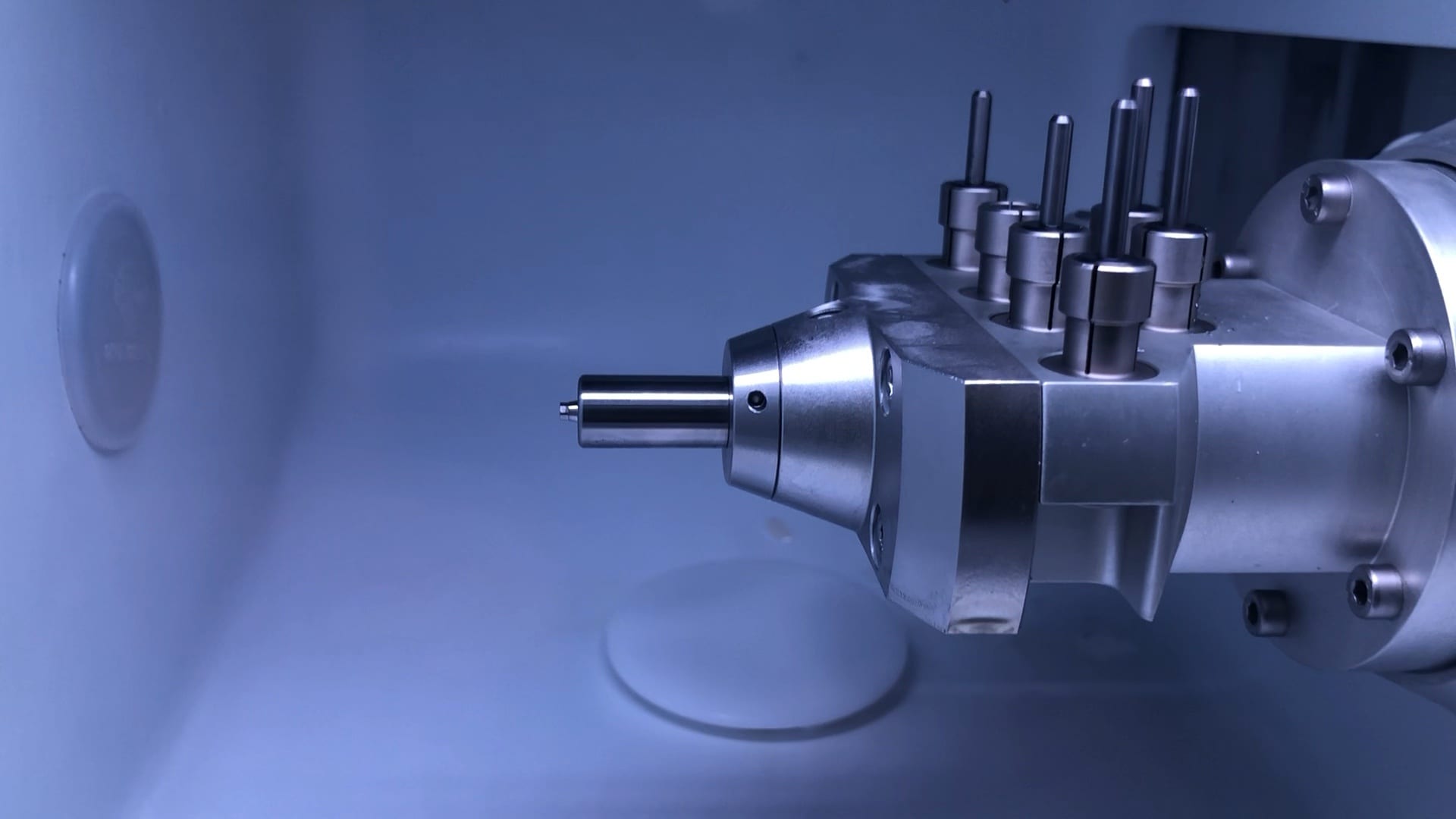

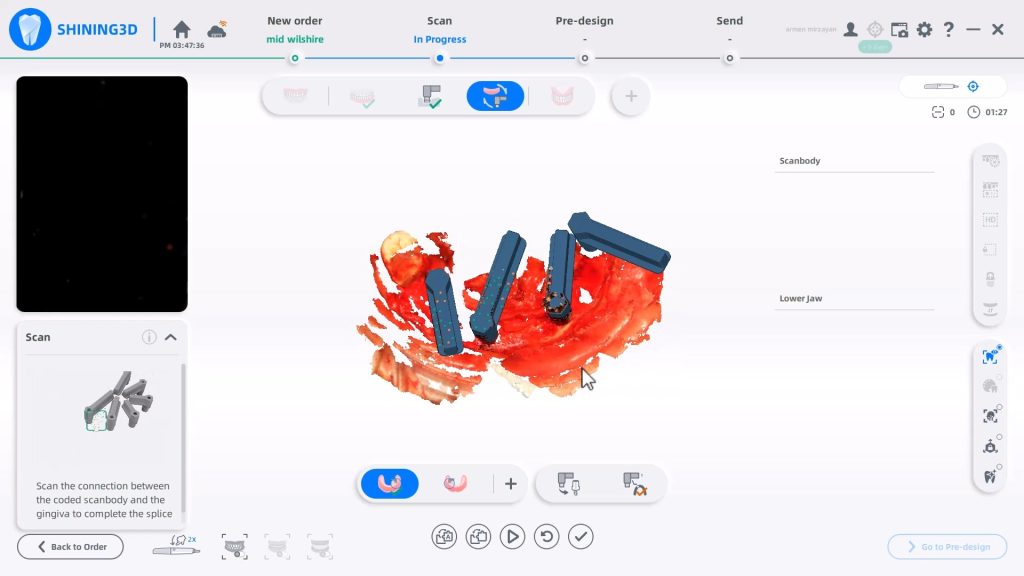

A custom titanium metal abutment is milled in such a manner where the drills DO NOT touch the connection. The type of connection is predetermined by the blank manufacturer and the cylindrical part of the abutment is milled out. This makes the symmetric geometry of the abutment a bit tricky for some to handle as indexing it properly to manage the timing of the connection is critical for easy delivery.

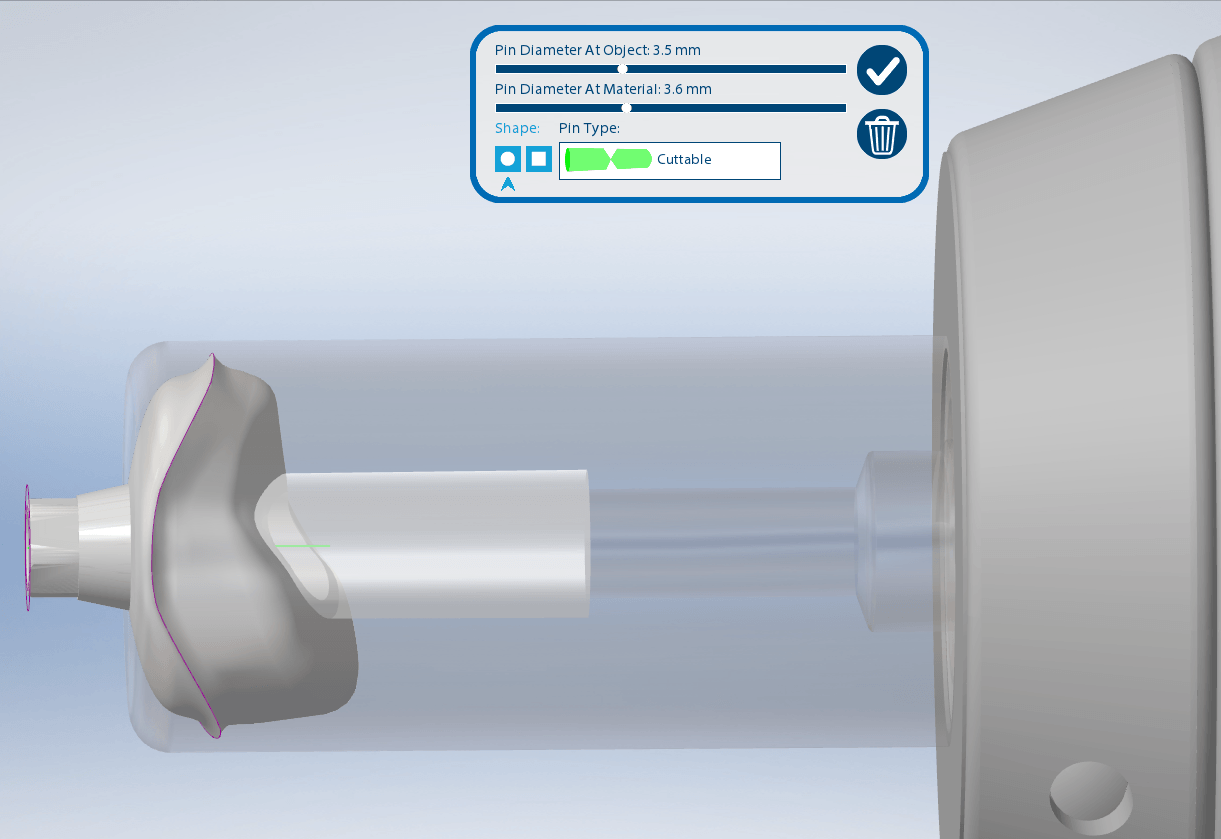

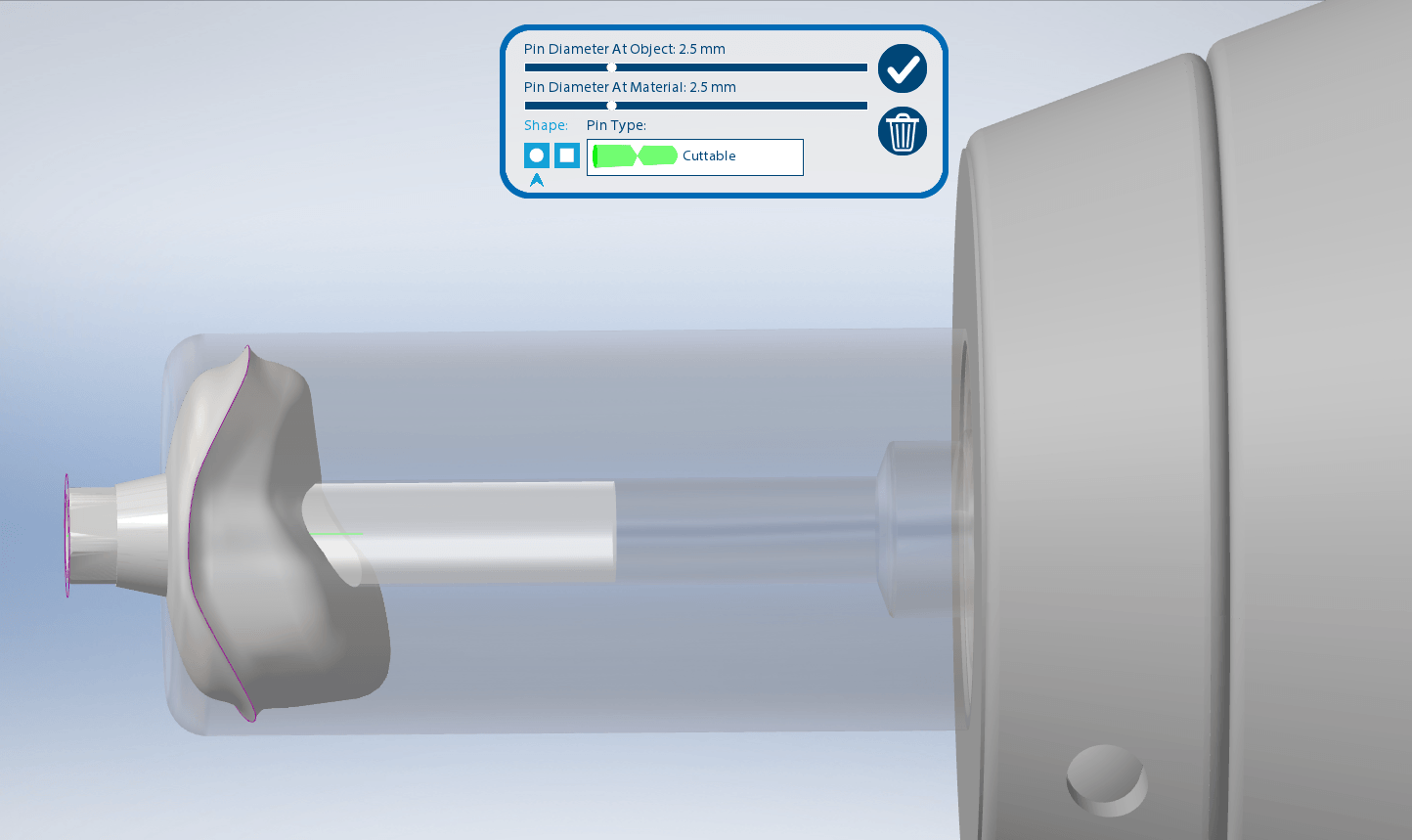

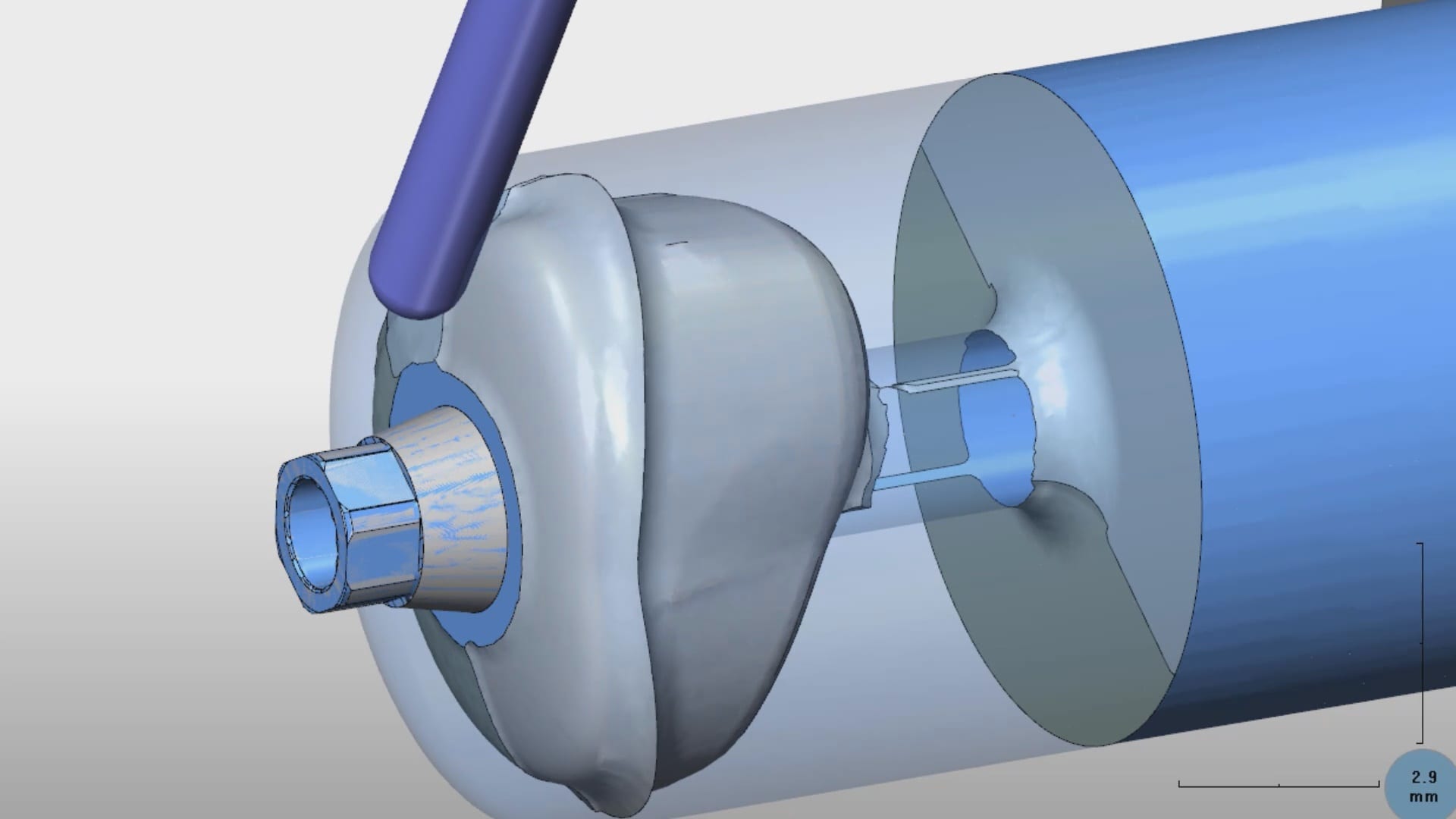

It is a good idea to know the exact dimension of the screw access hole. You want to set the diameter just outside the channel so that you don’t have to do a lot of post production adjustments. if it is made too thin however, you can have a mis-mill and have to repeat it. We’ve found 2.5 mm the perfect setting for the DESS titanium abutments.

Download this case to mill and see the results for yourself

You must log in to post a comment.