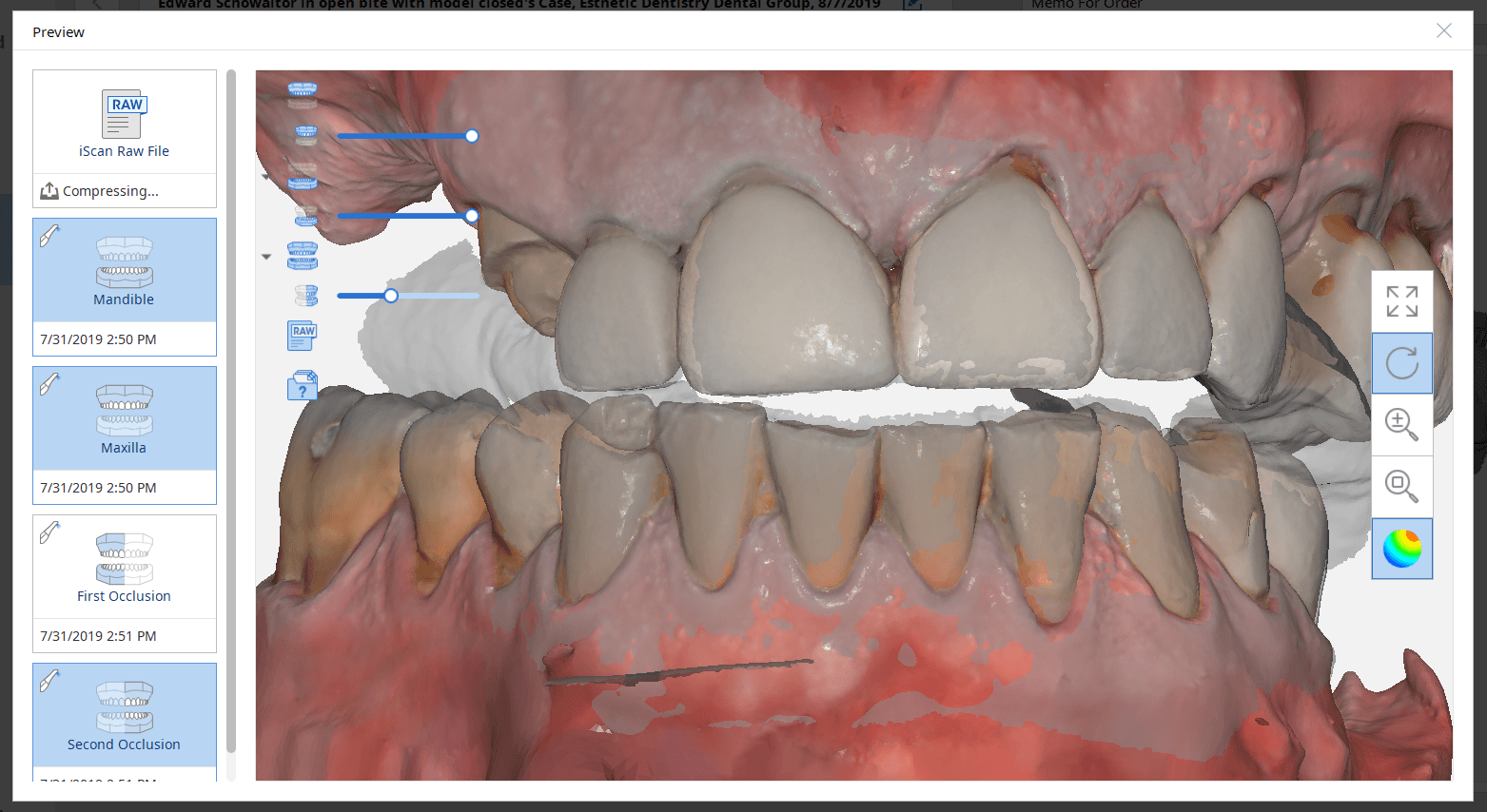

In this case presentation, we feature a crown that needs to be replaced due to open margins and recurrent decay.

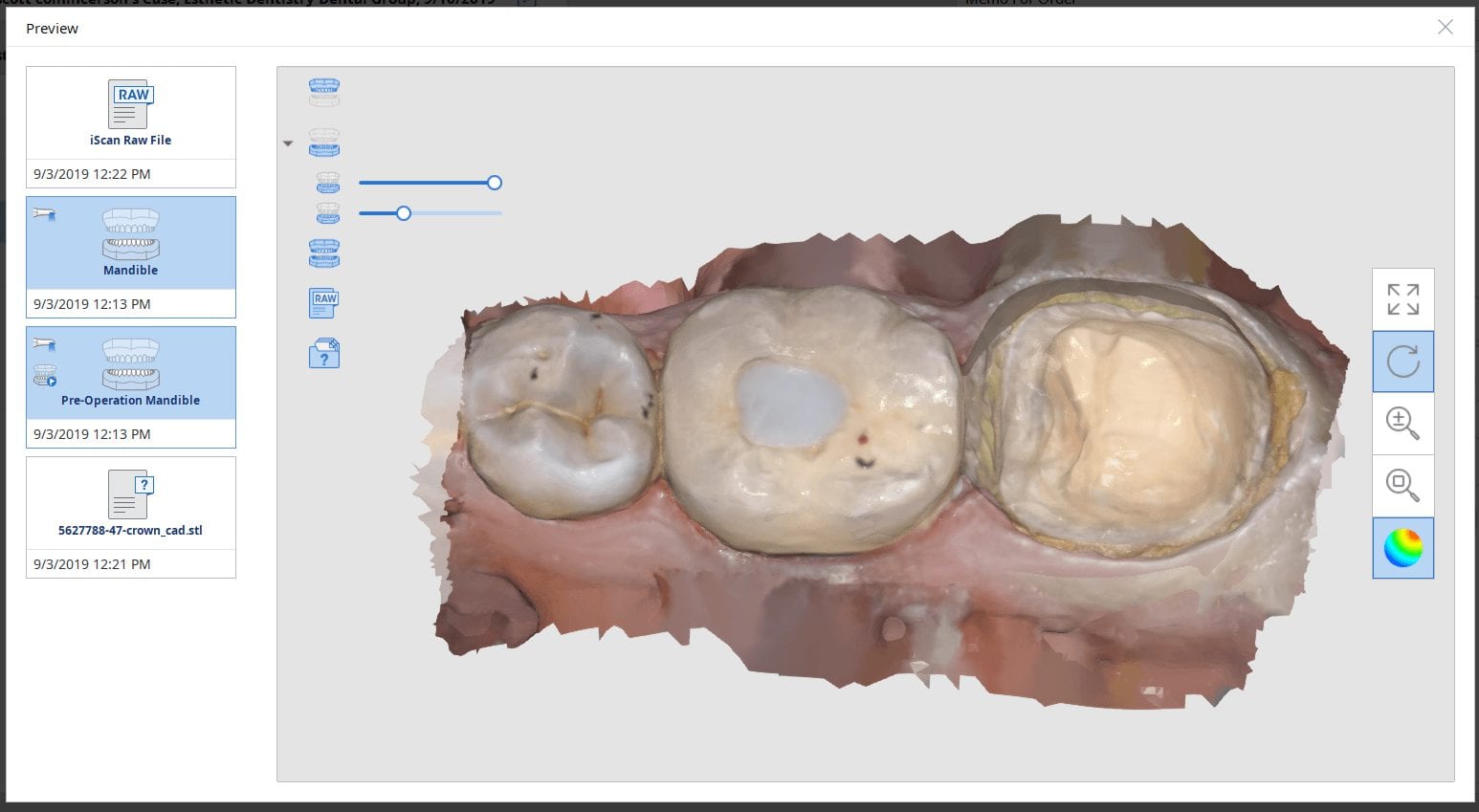

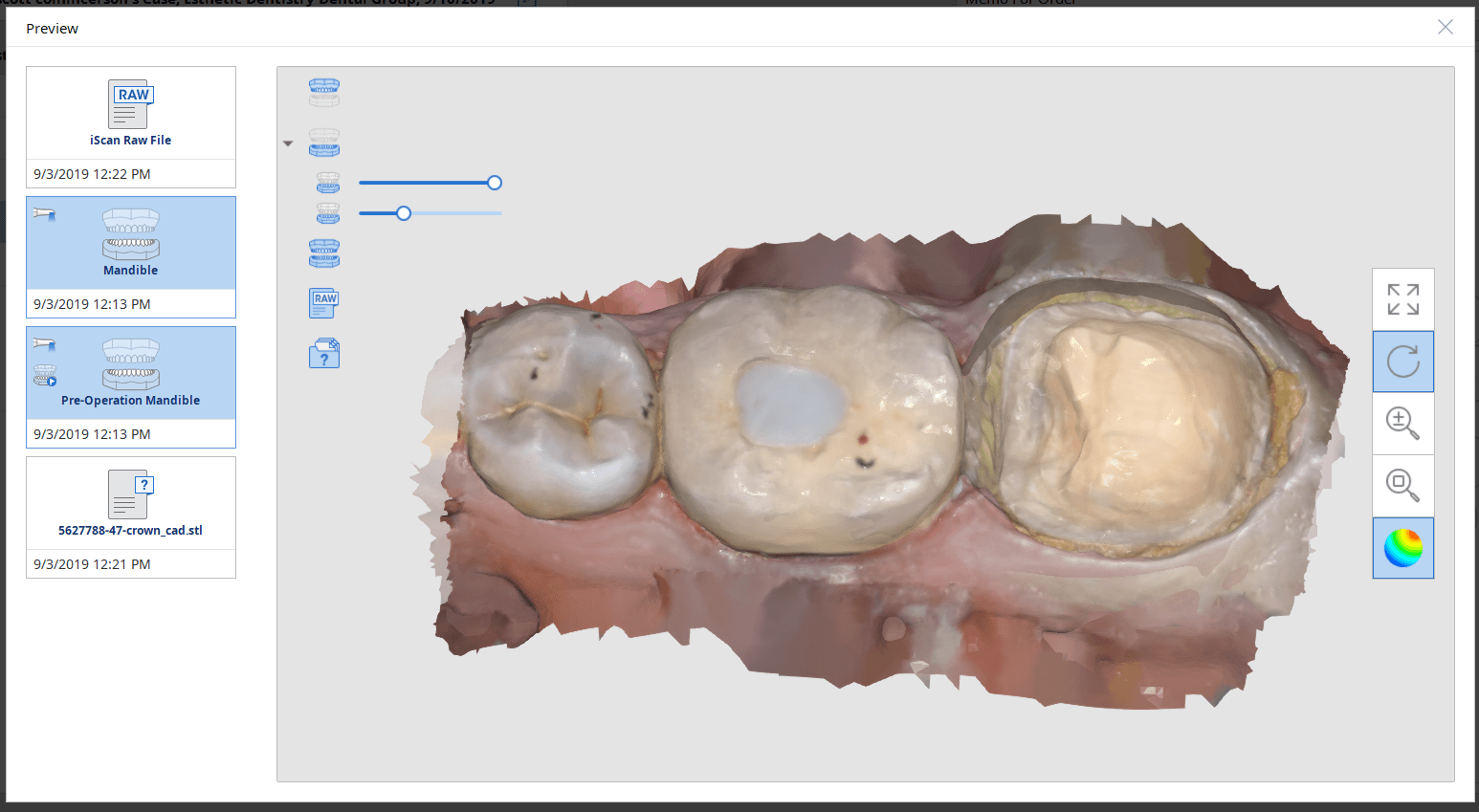

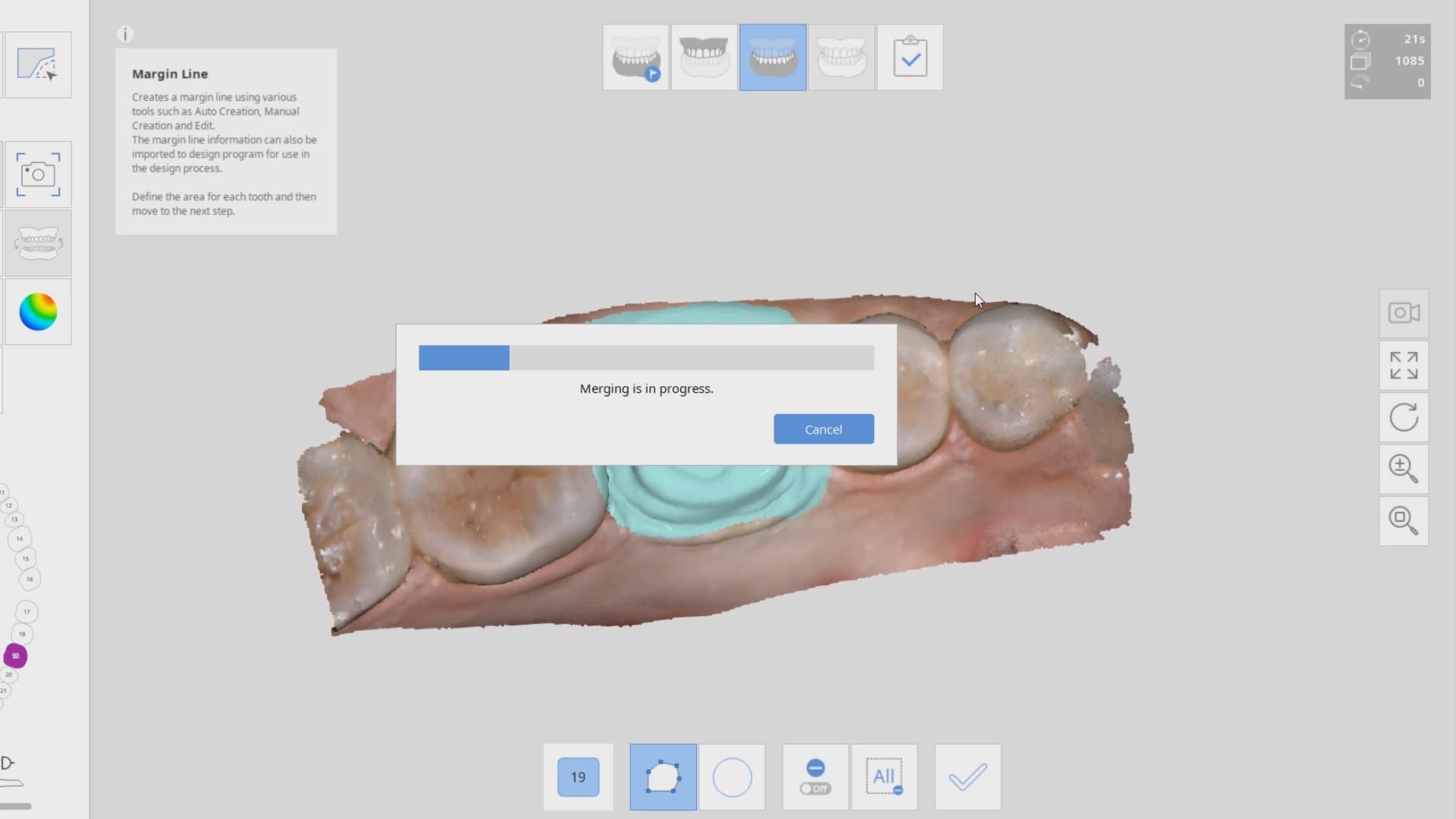

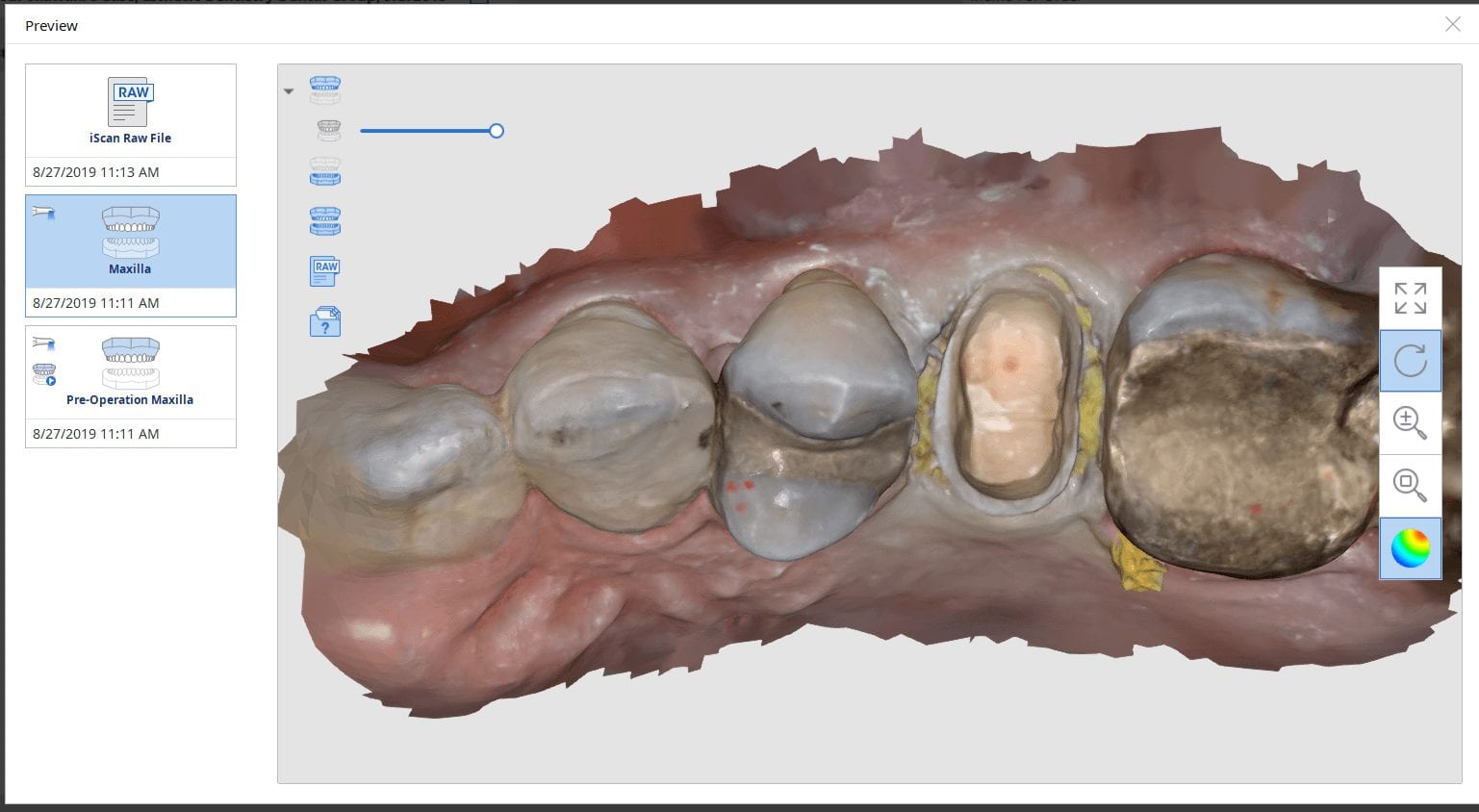

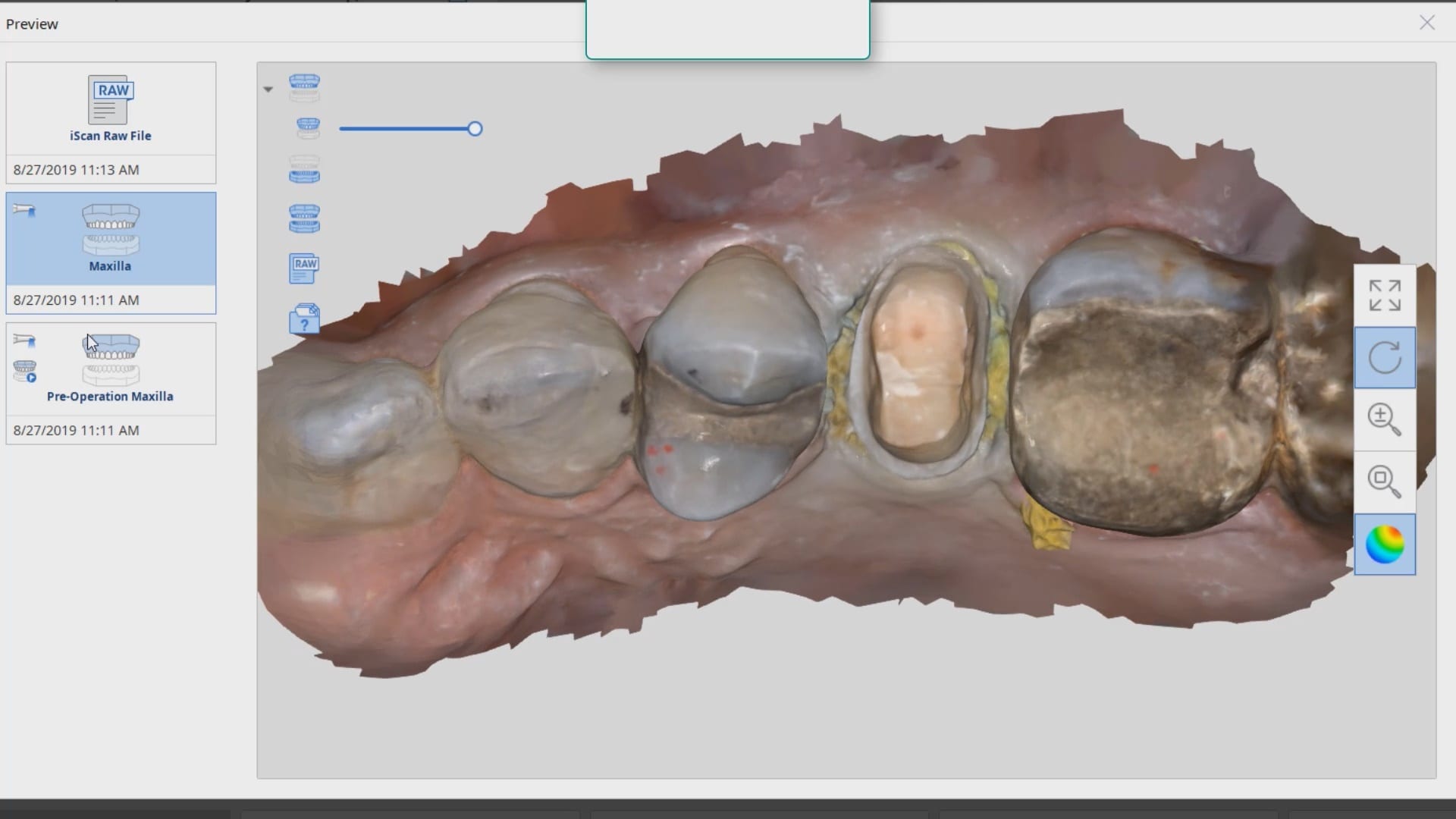

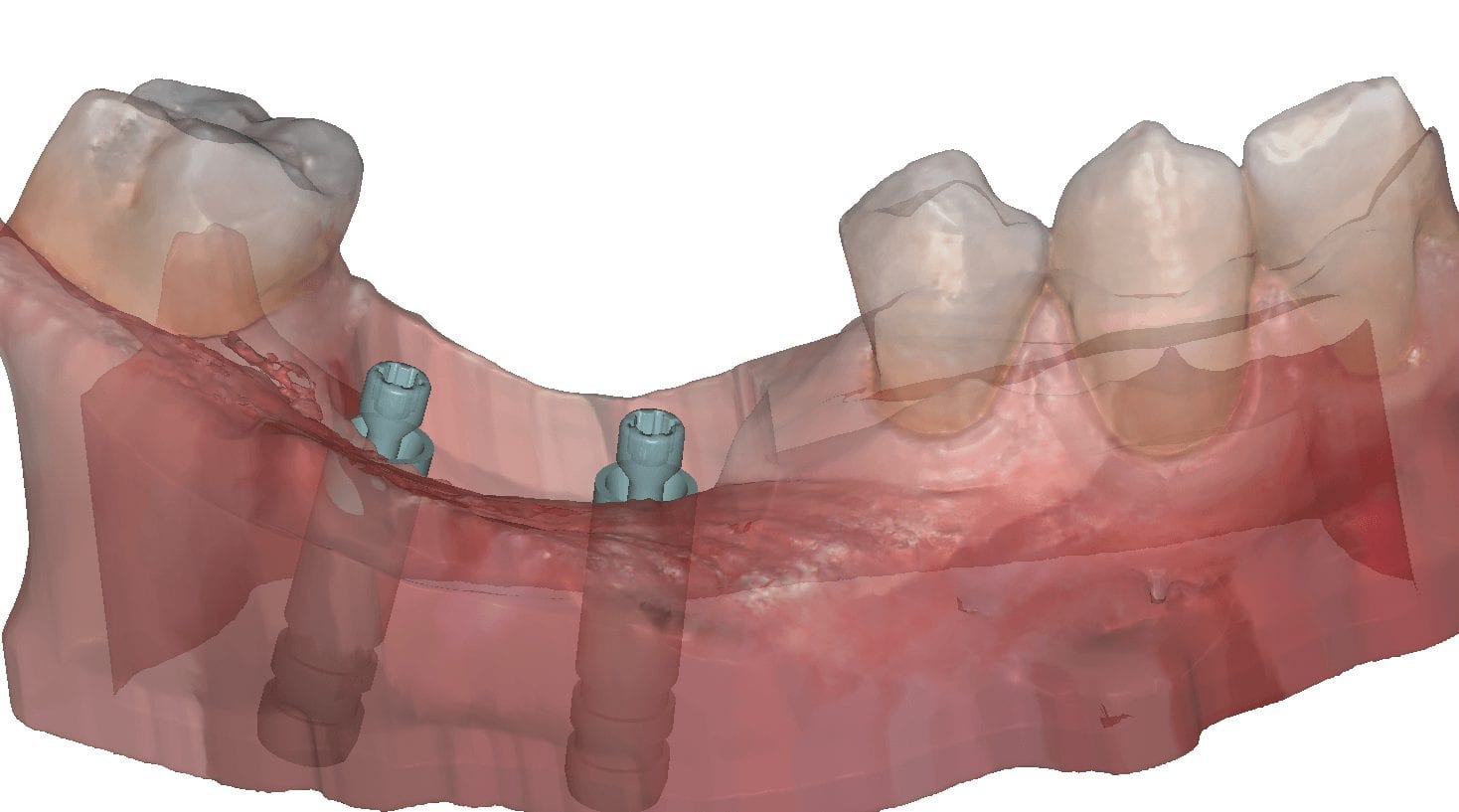

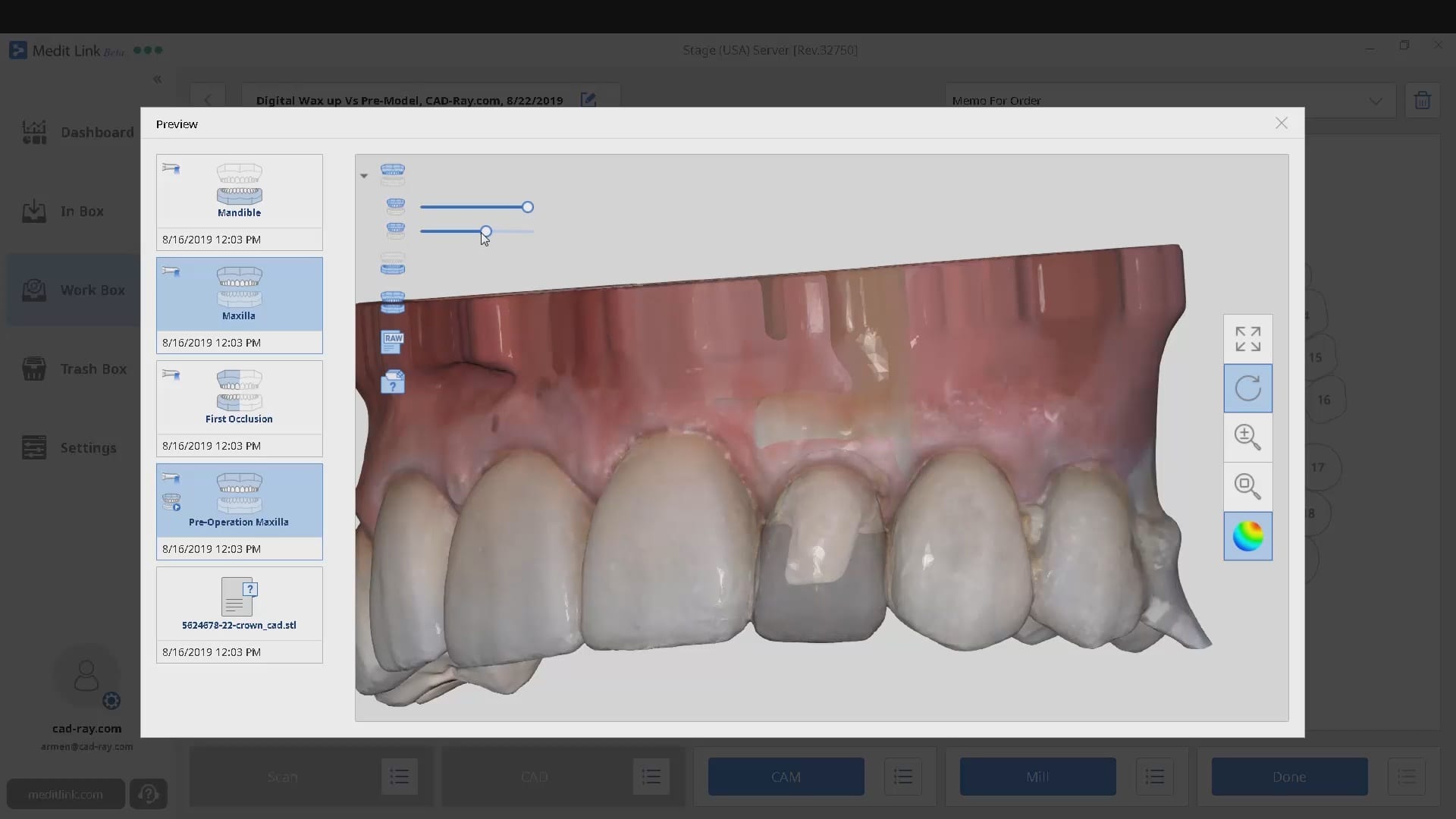

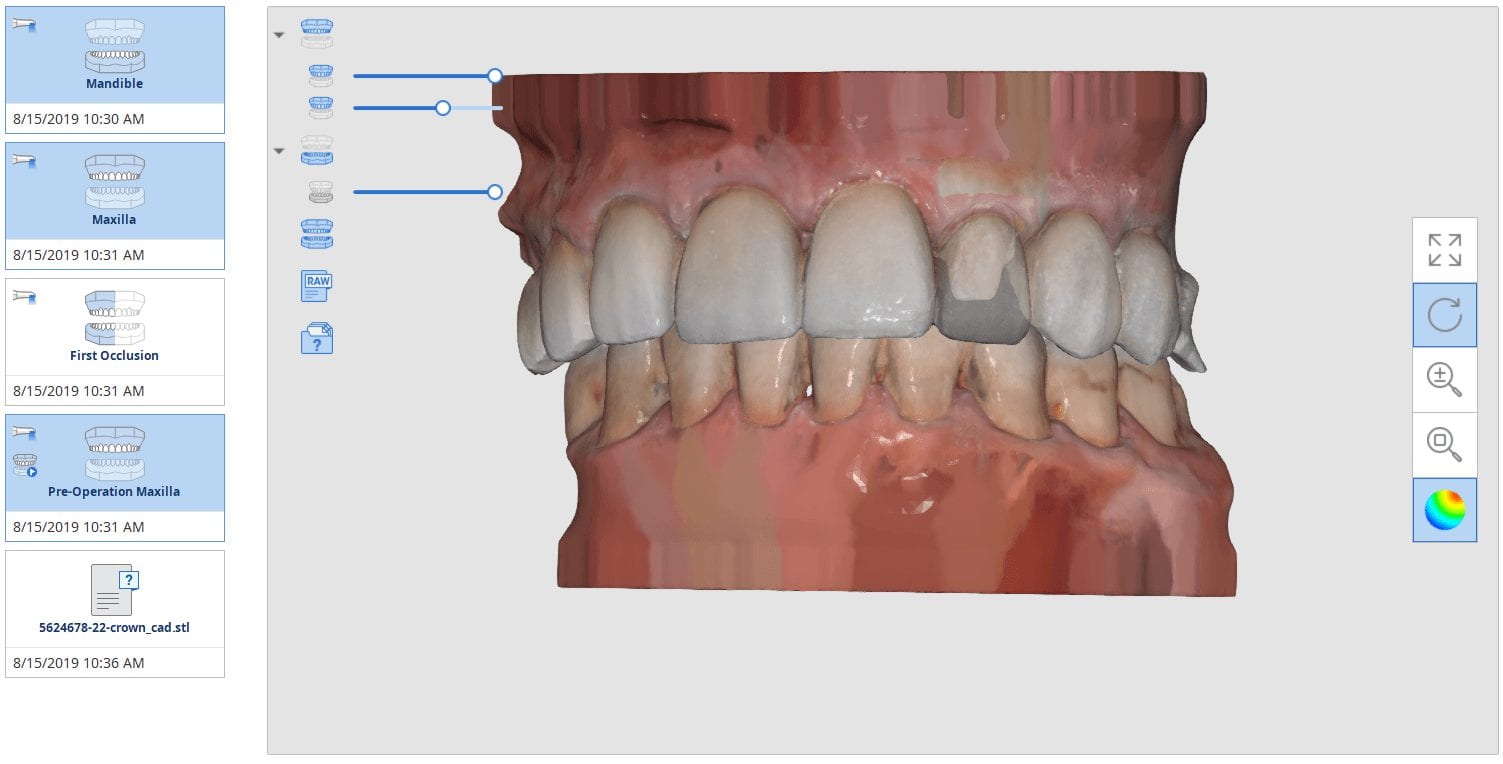

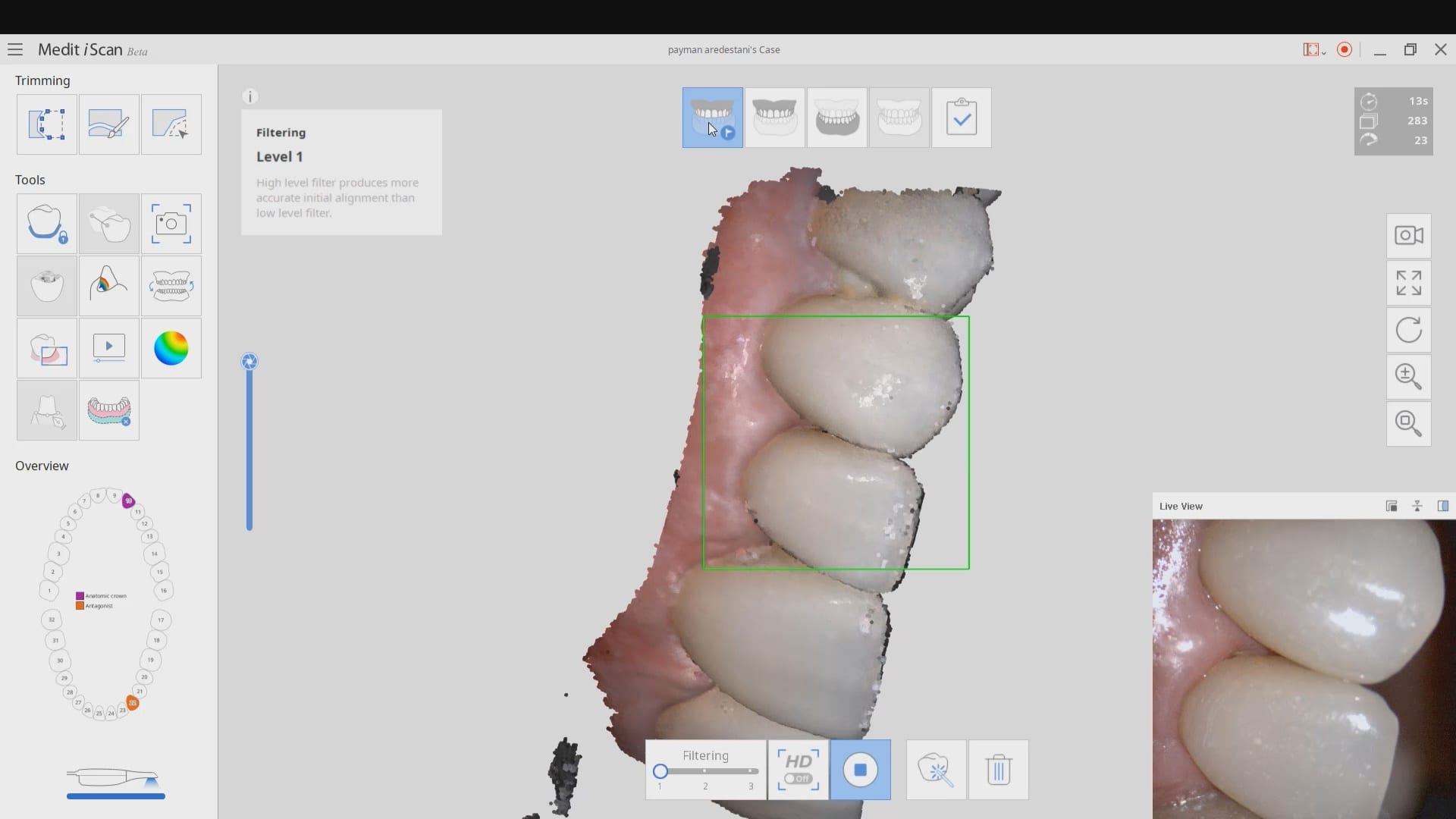

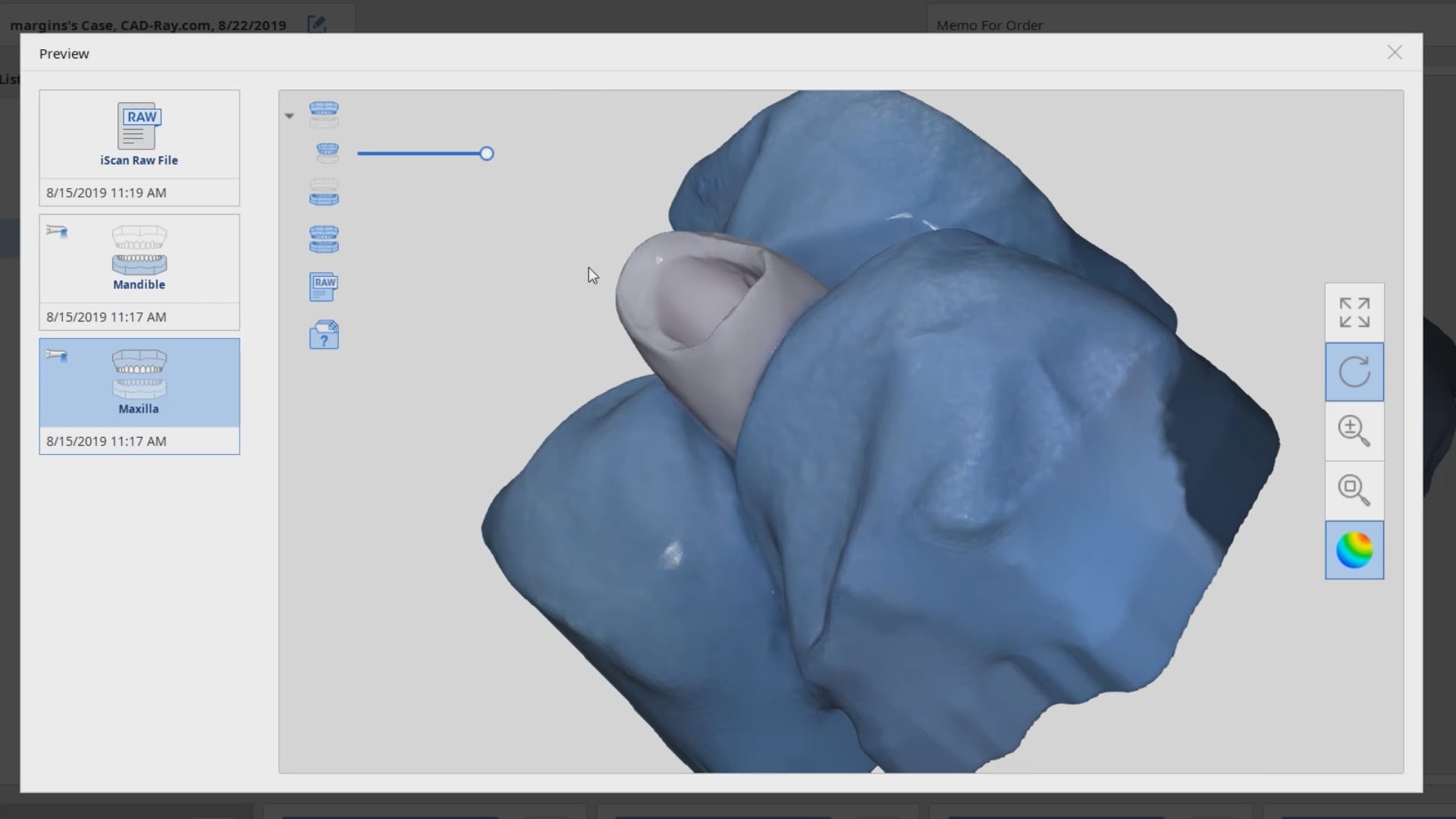

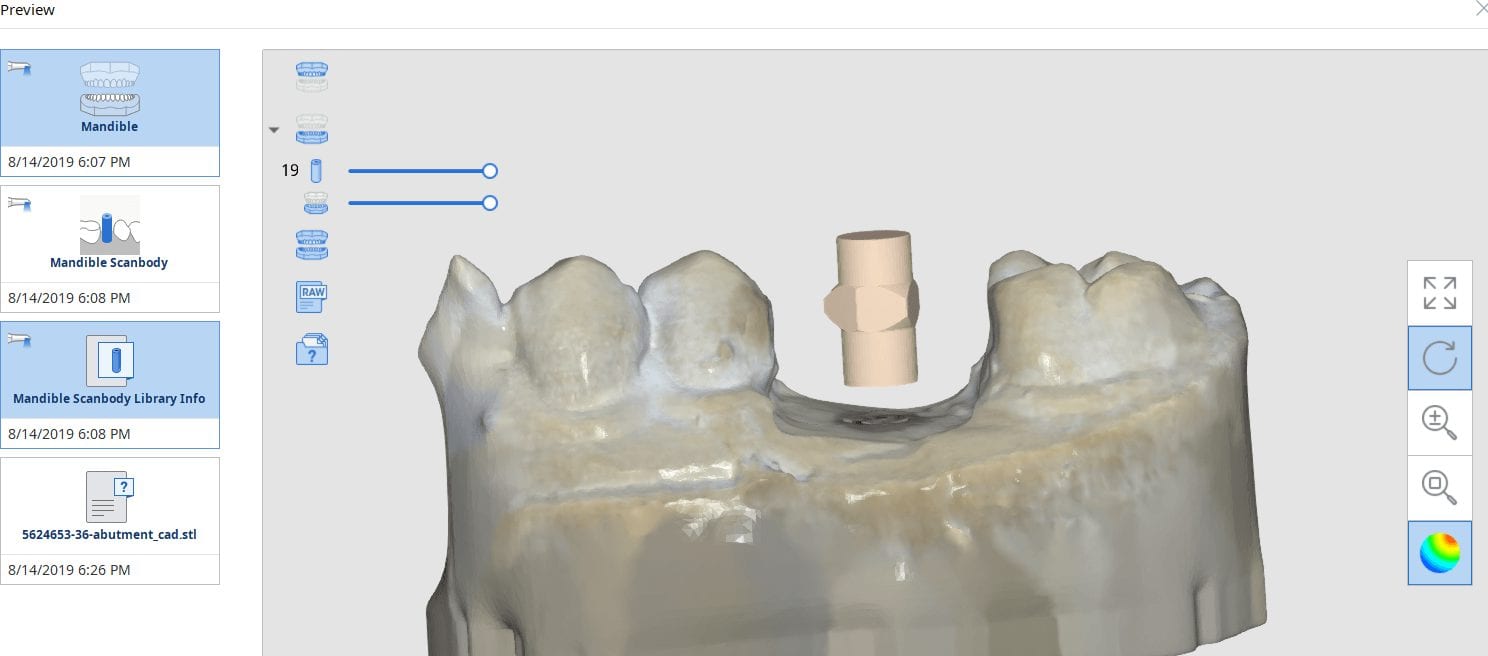

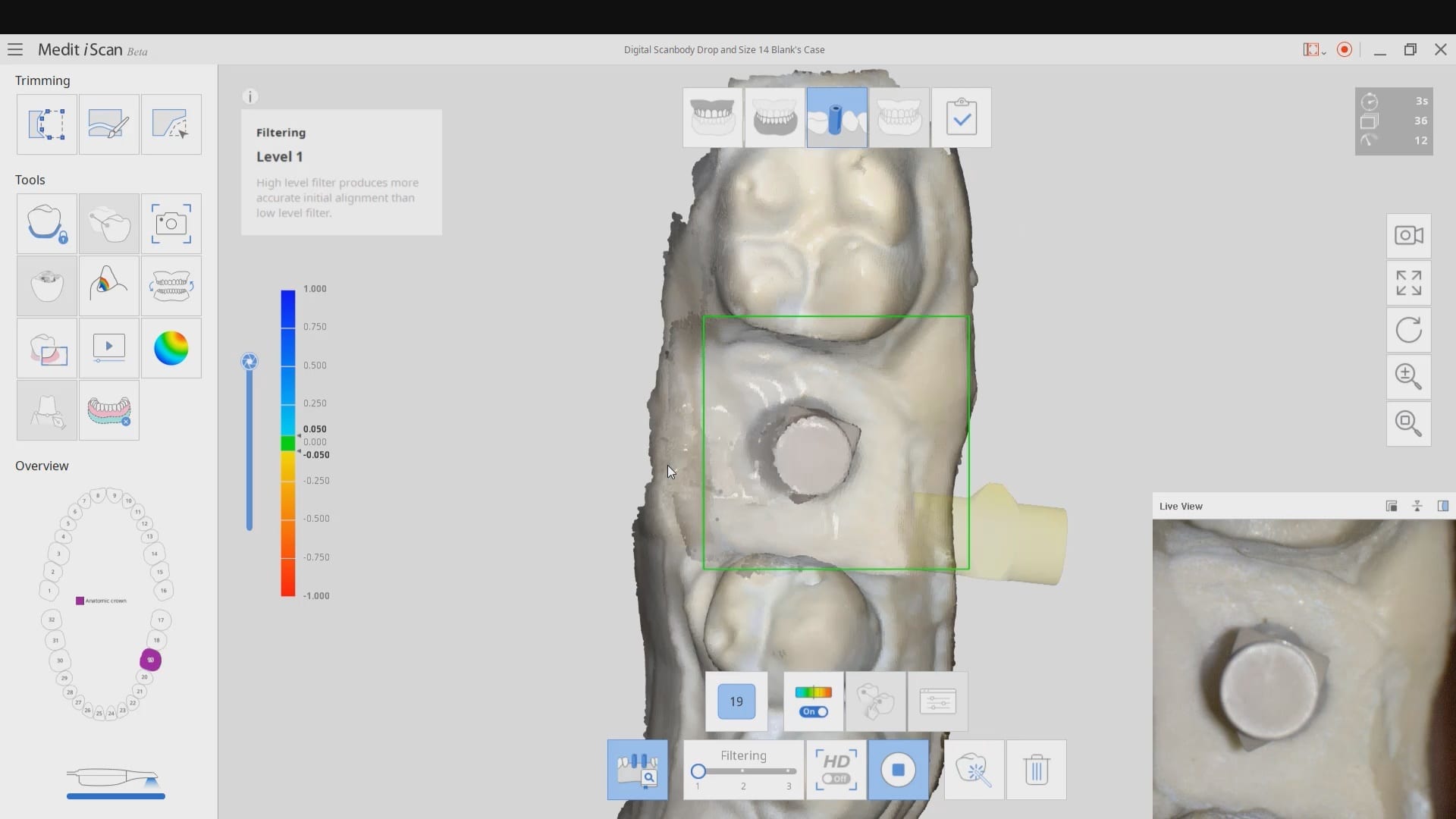

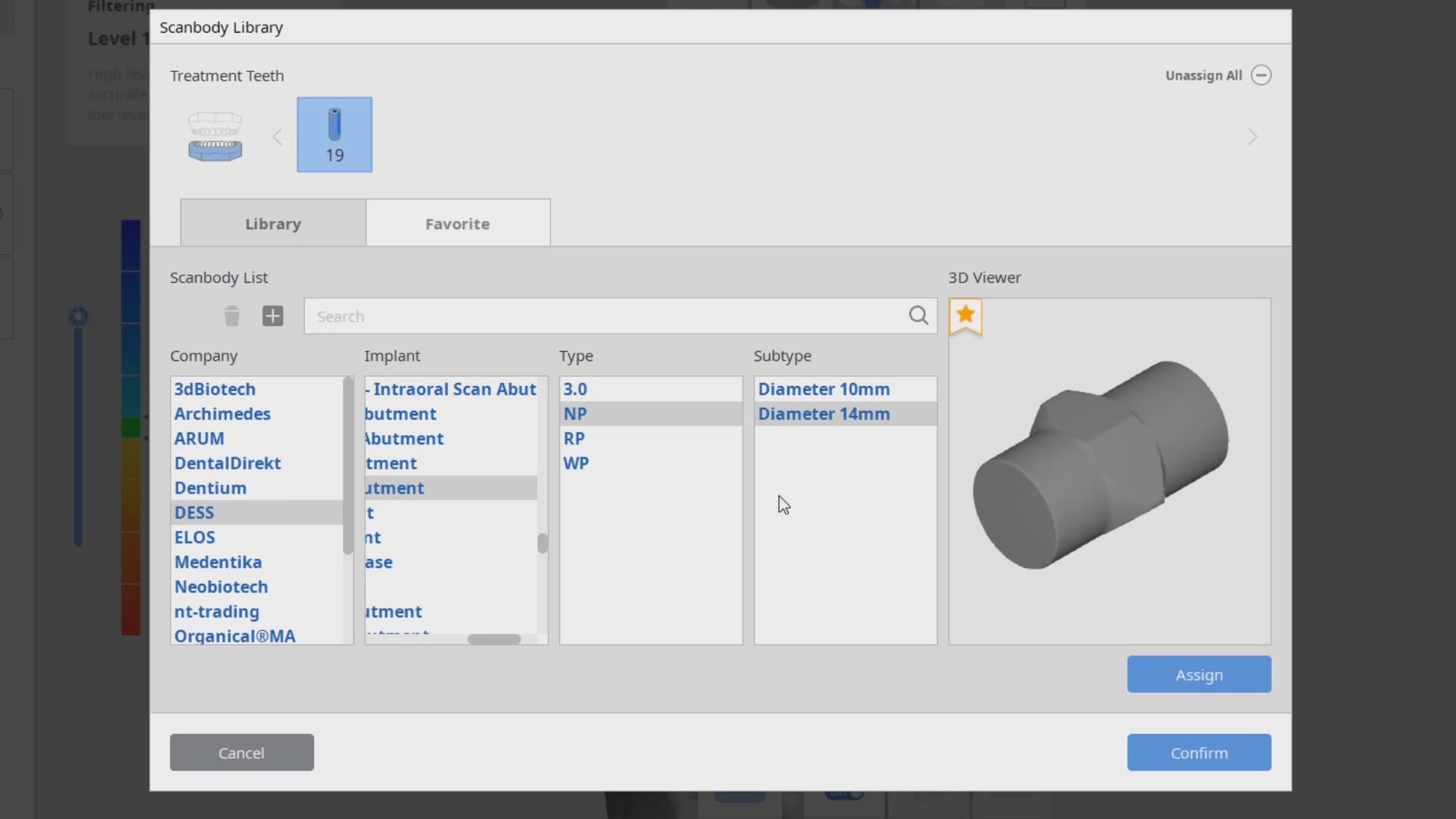

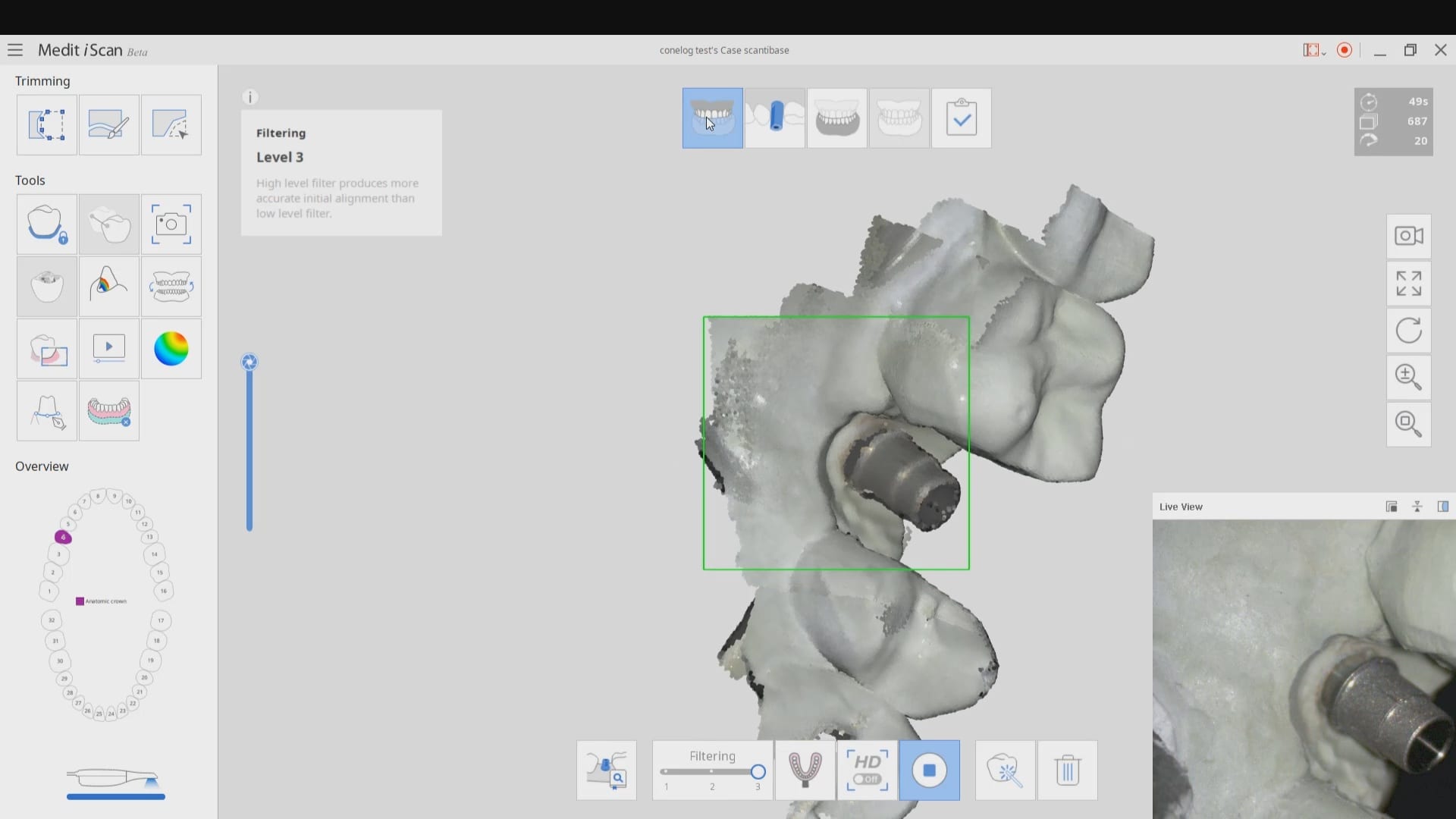

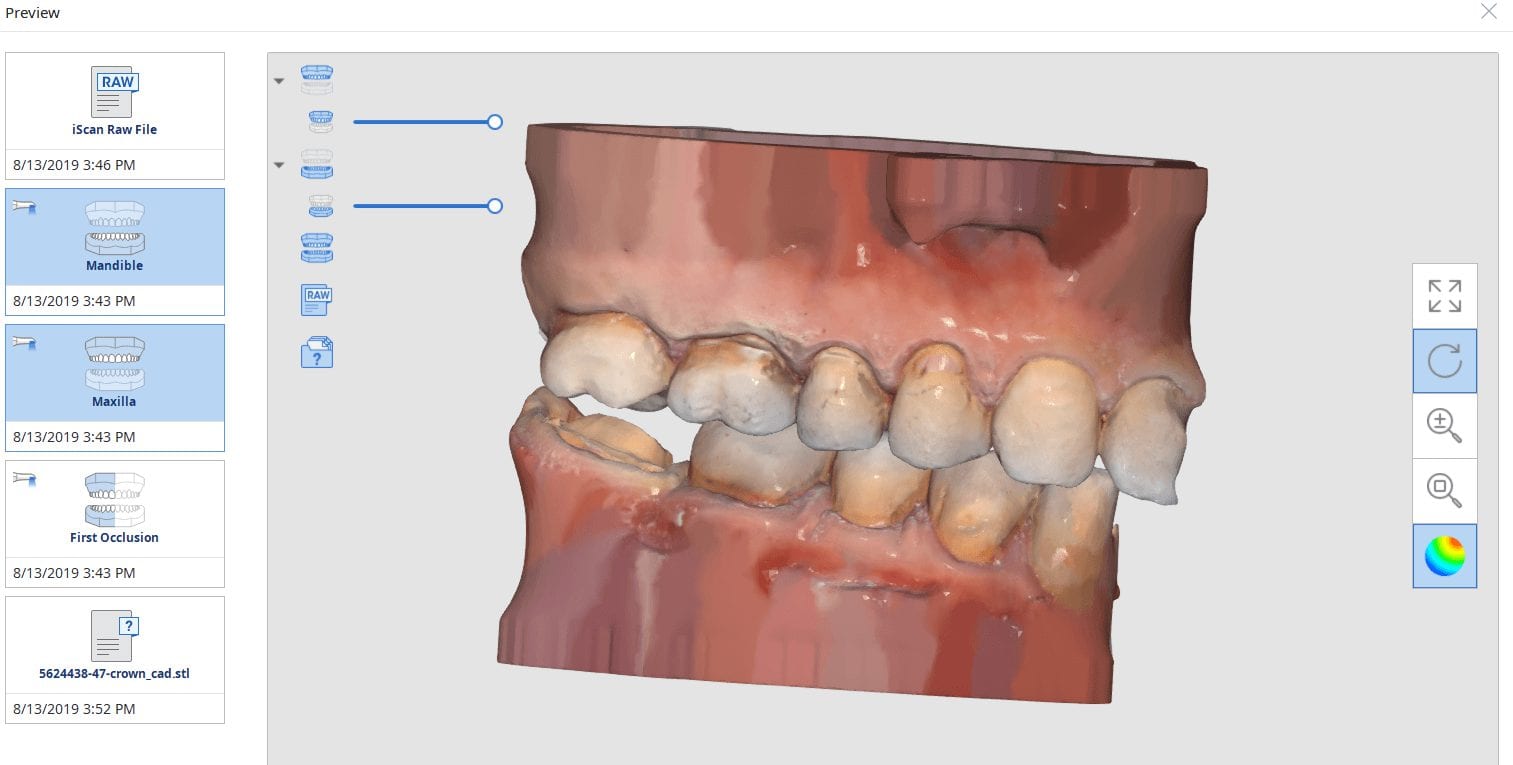

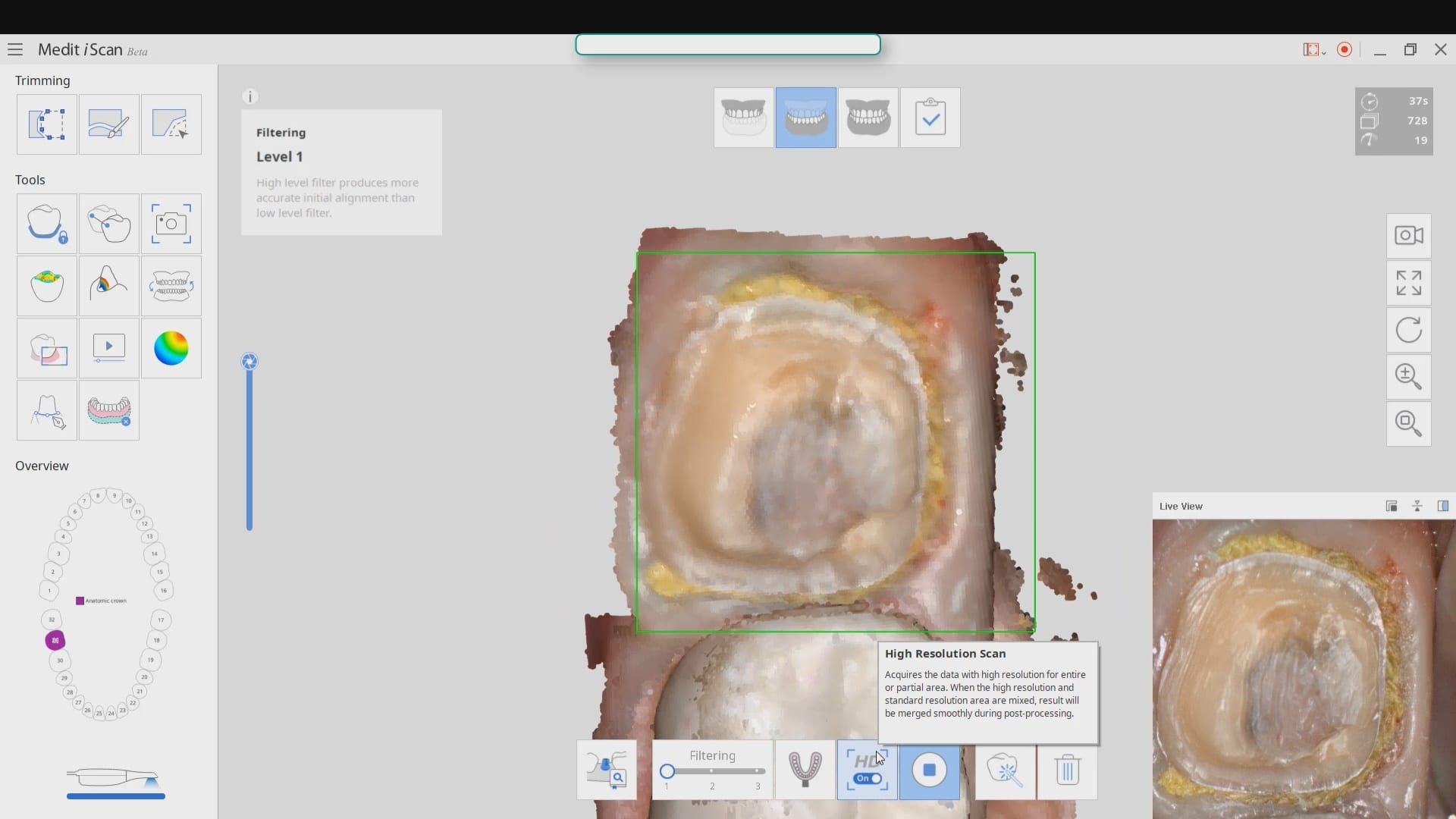

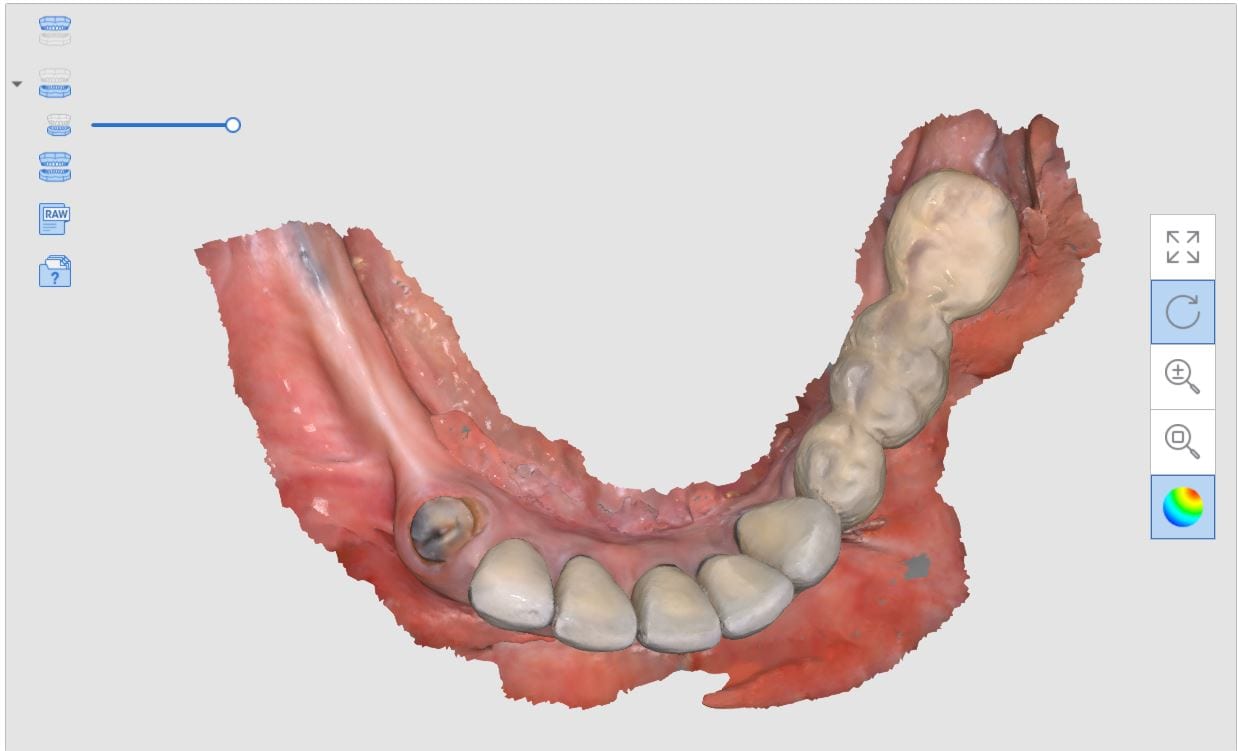

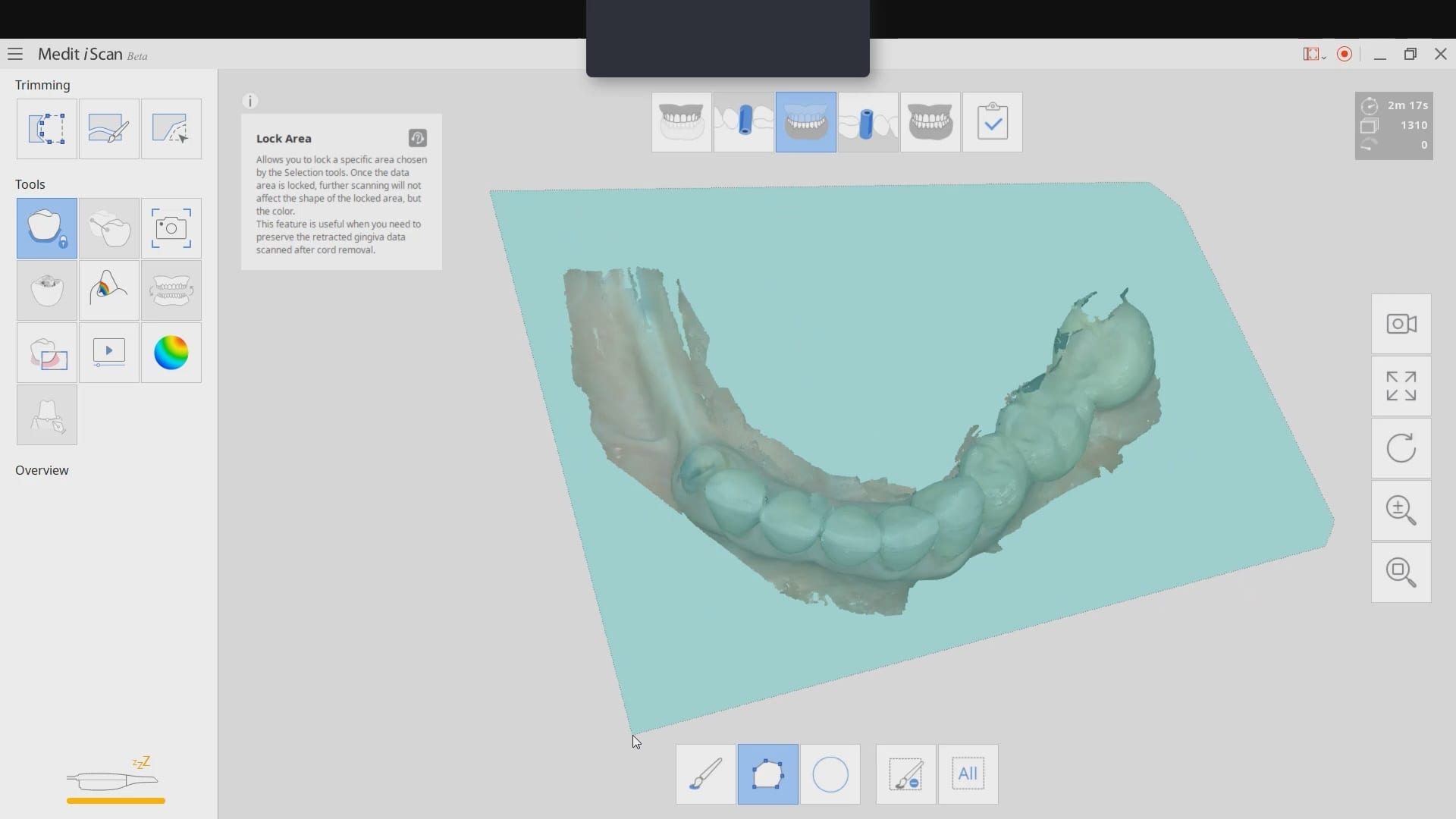

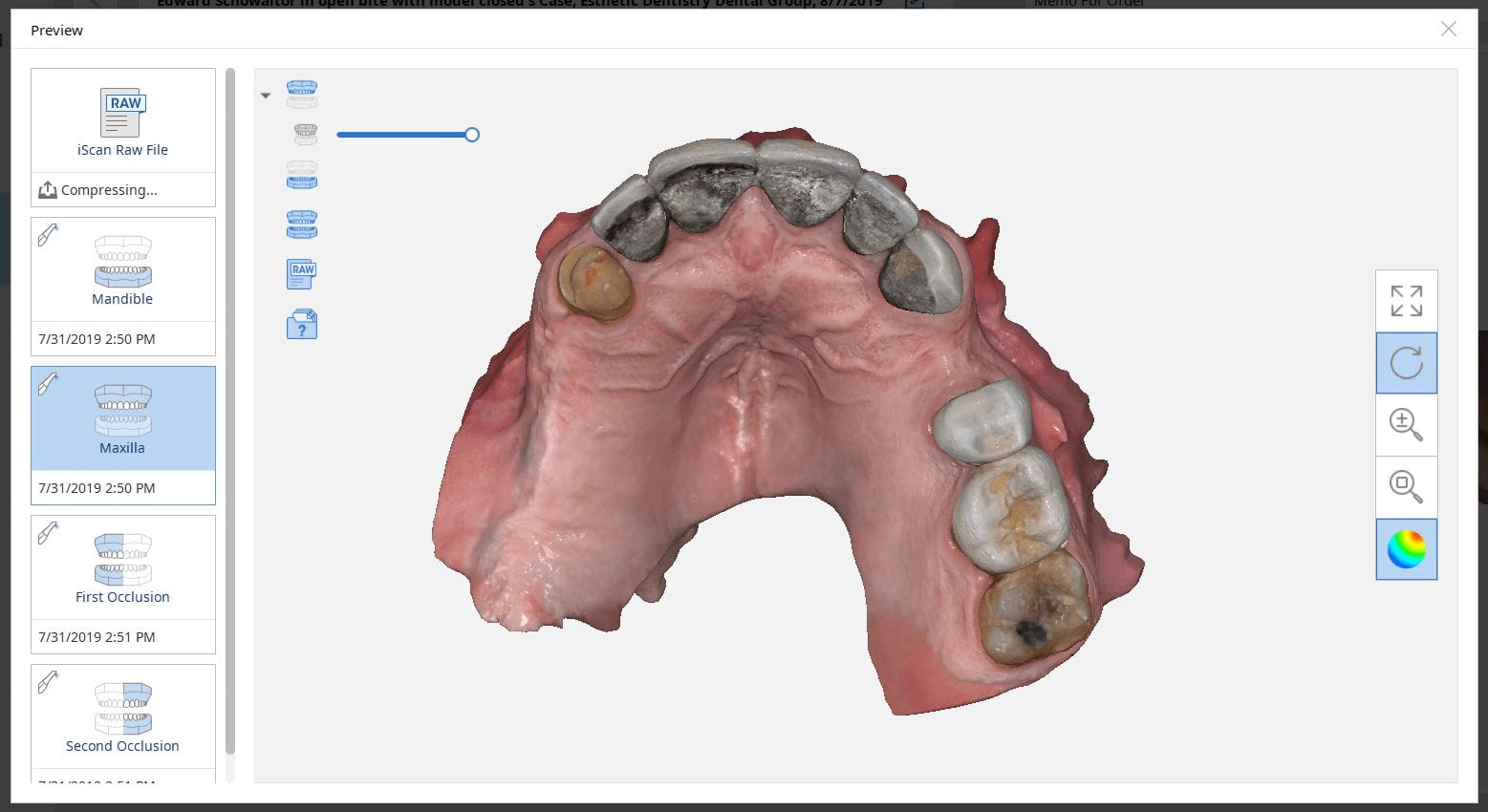

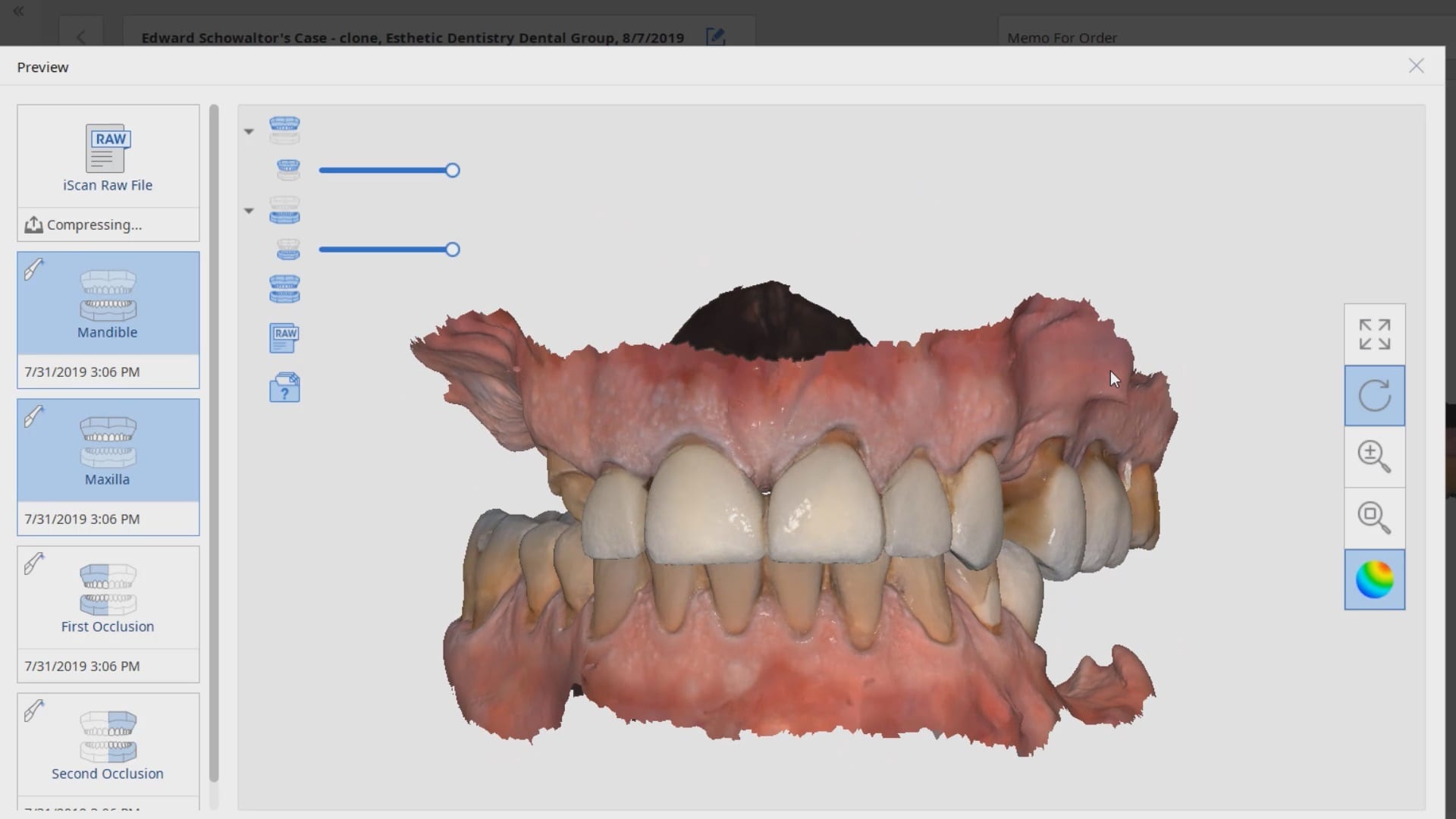

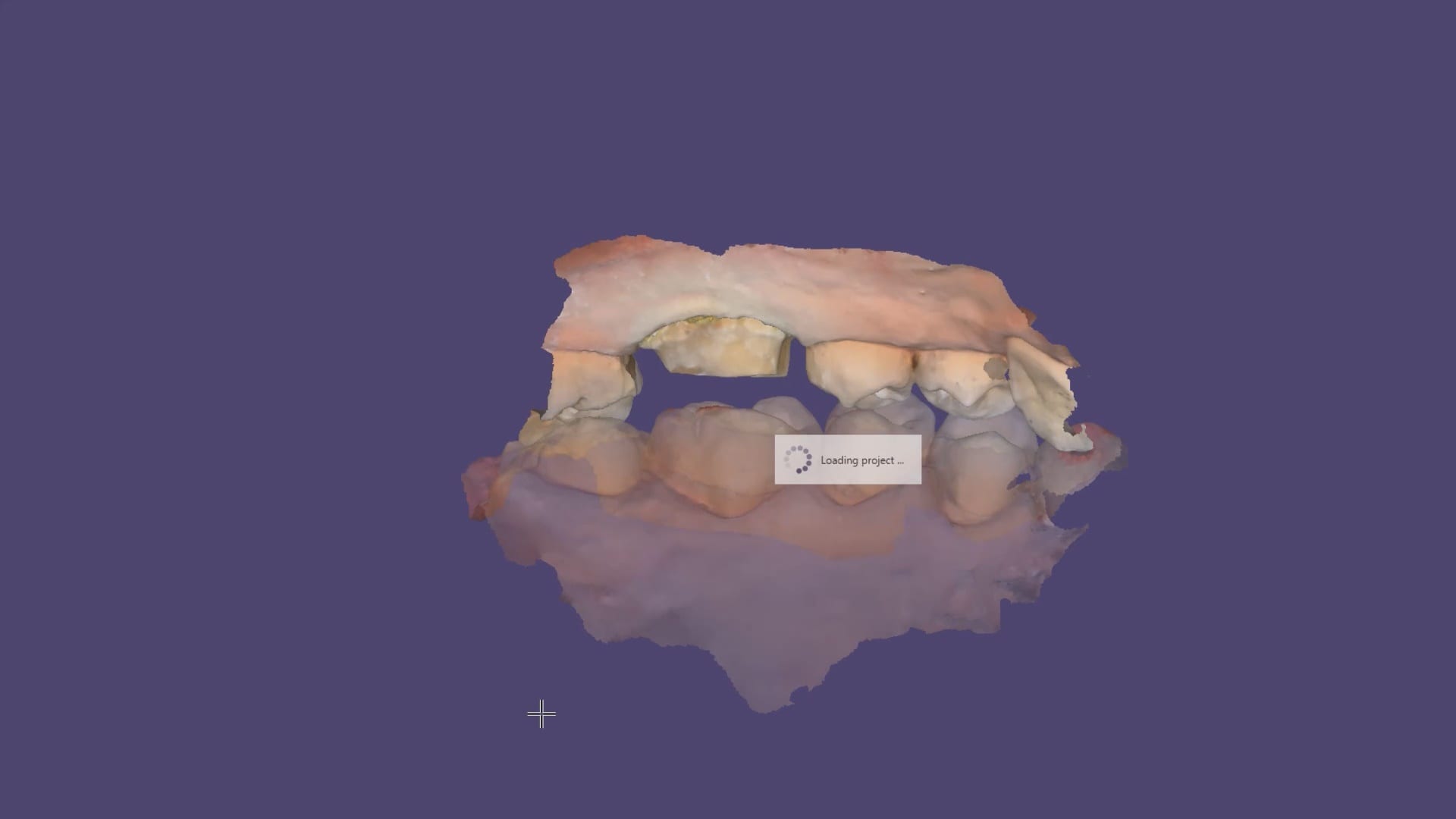

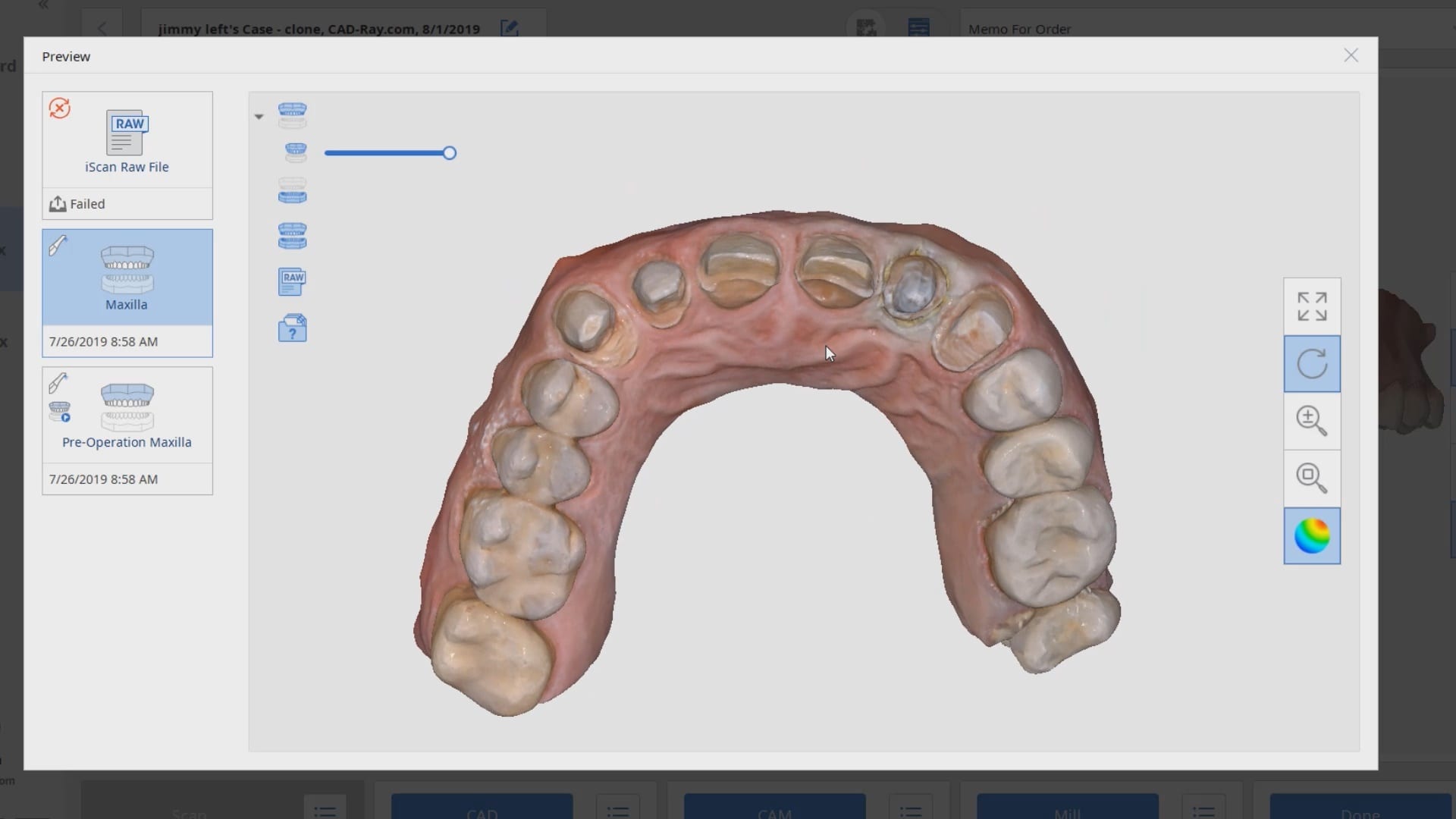

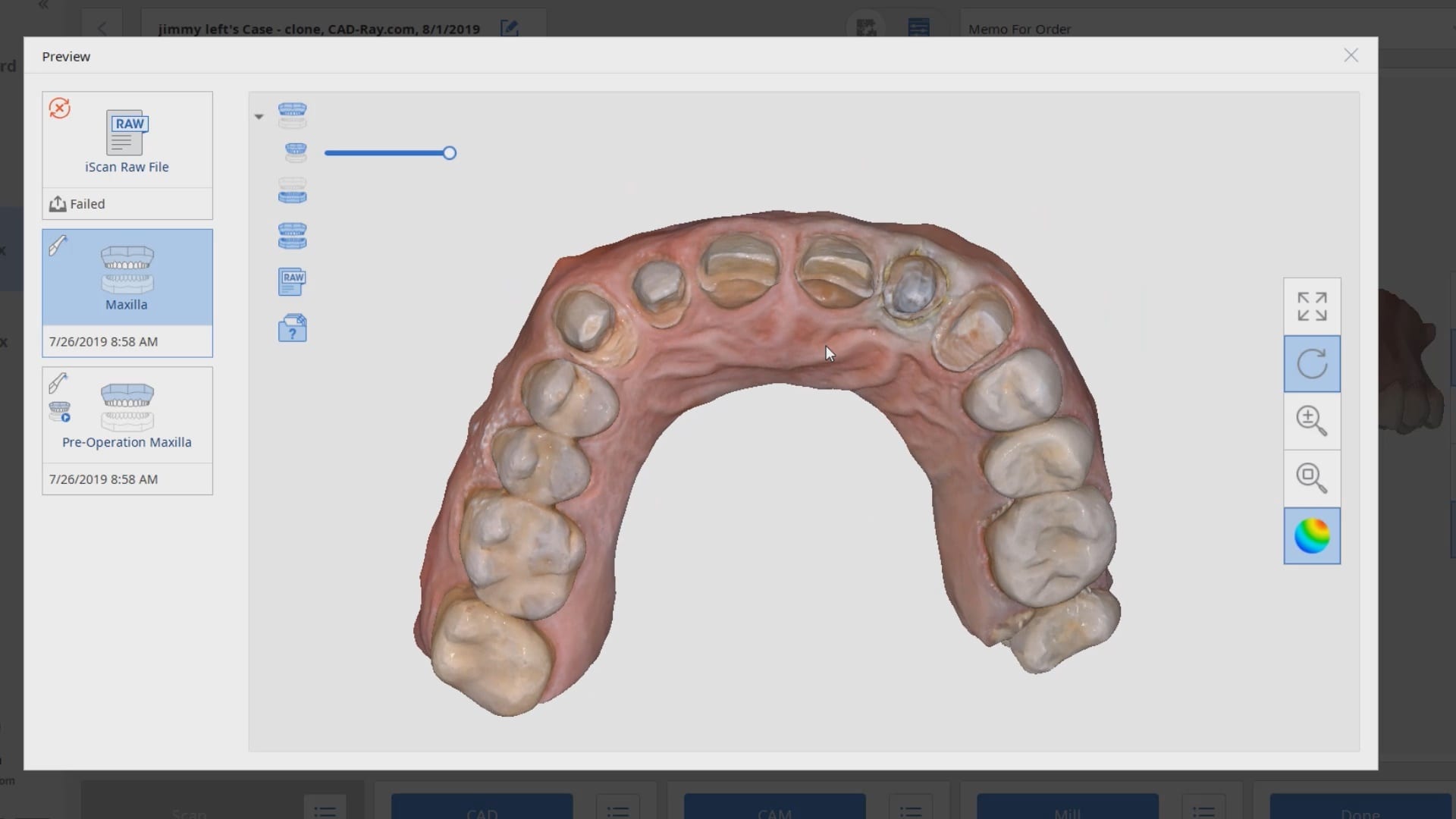

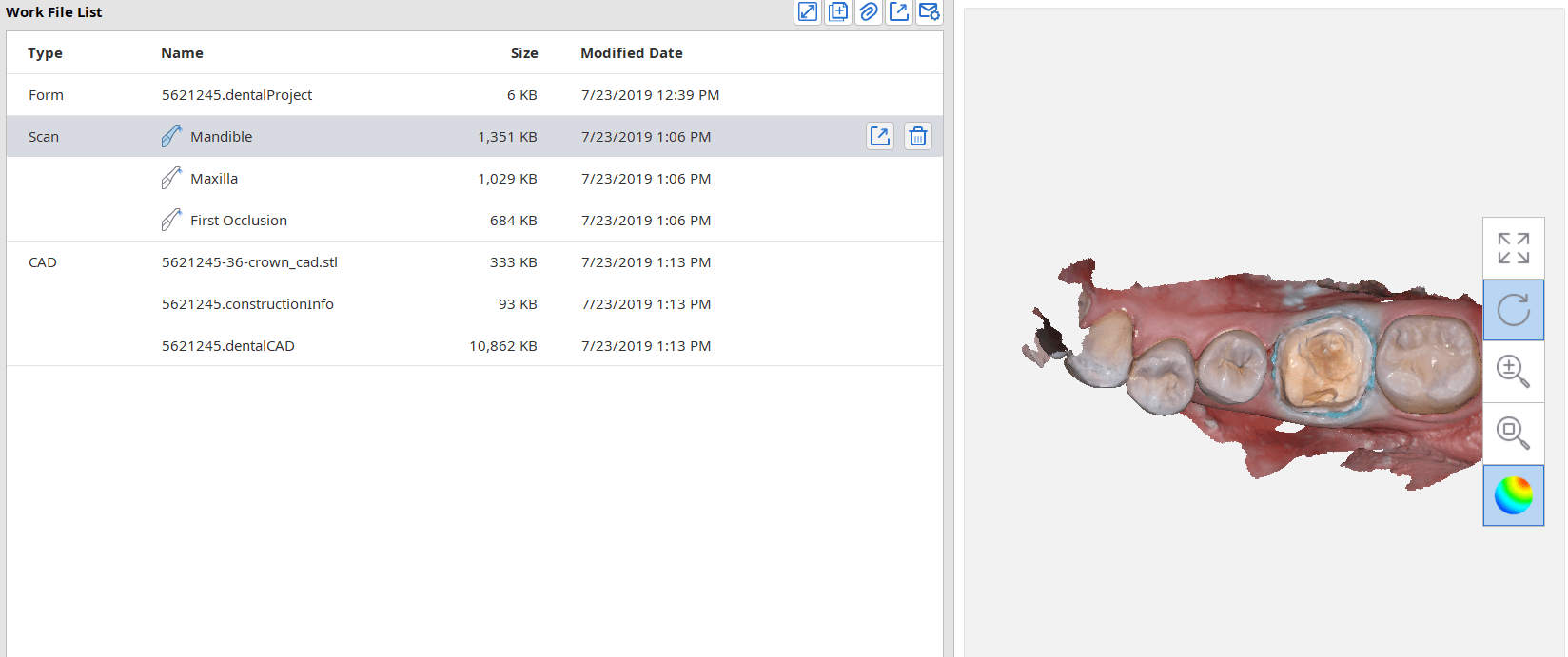

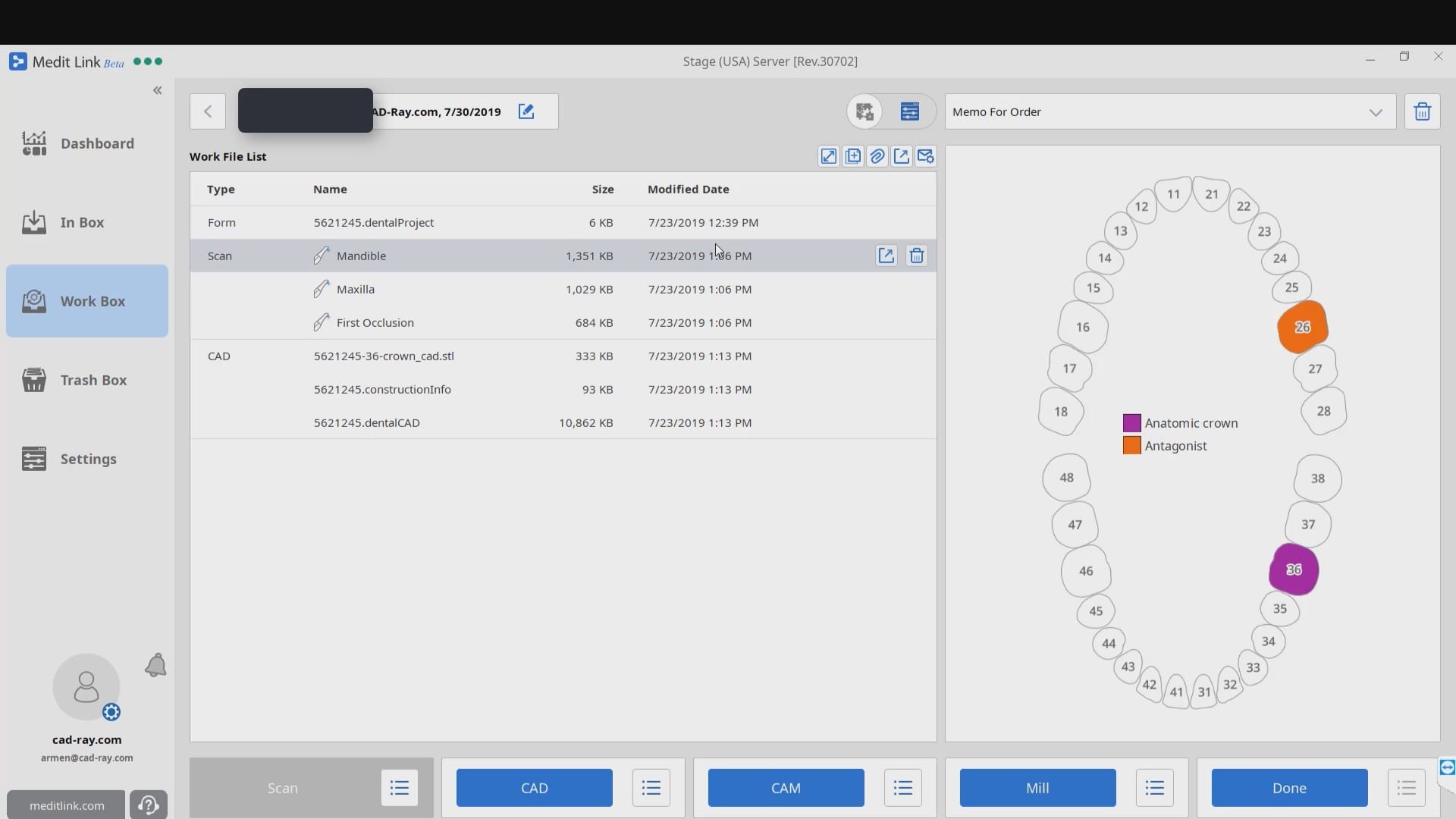

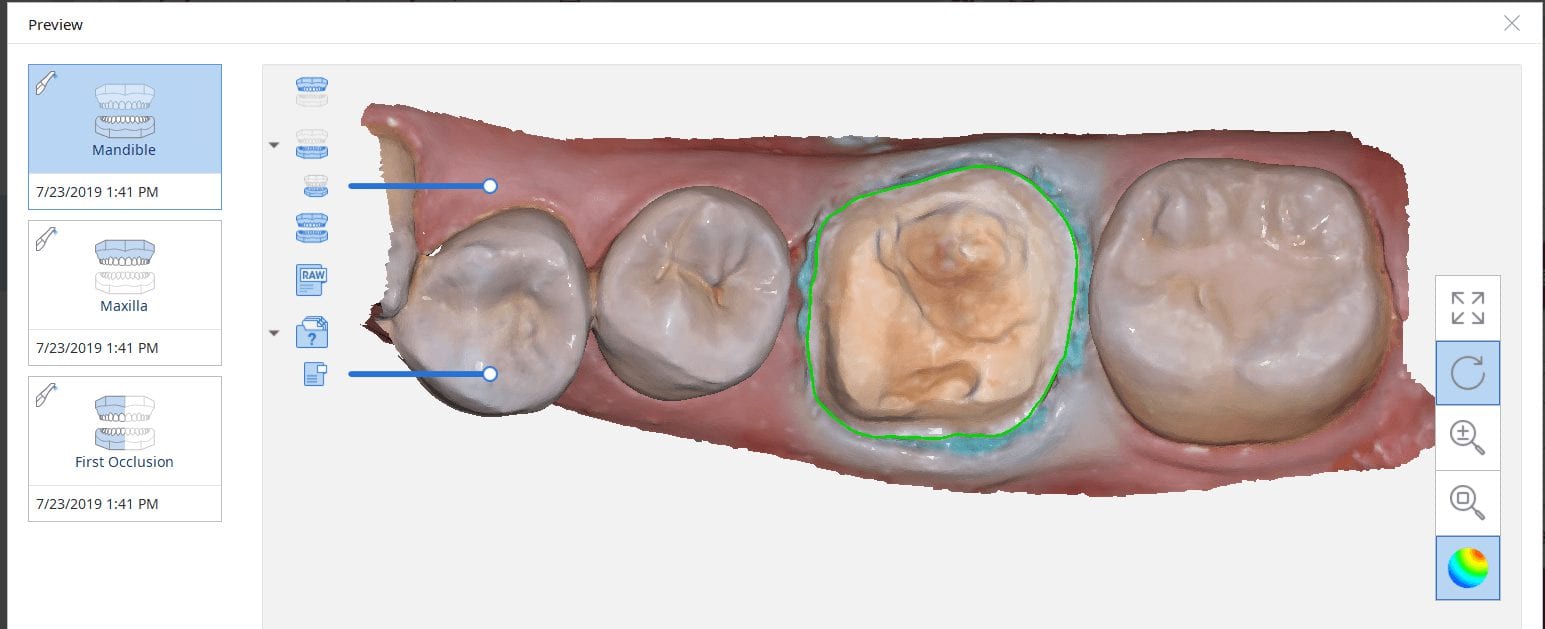

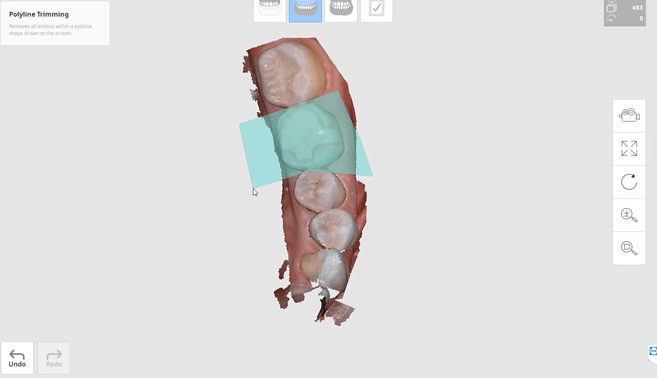

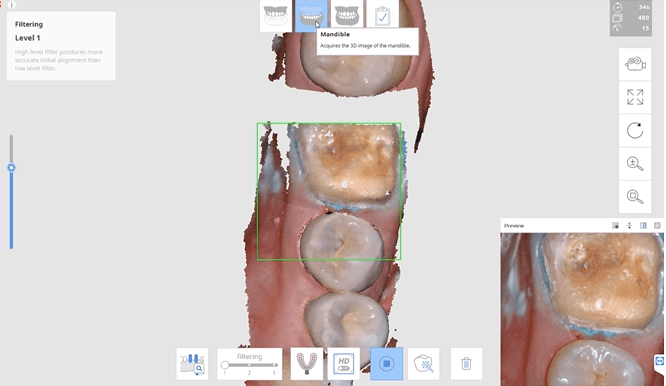

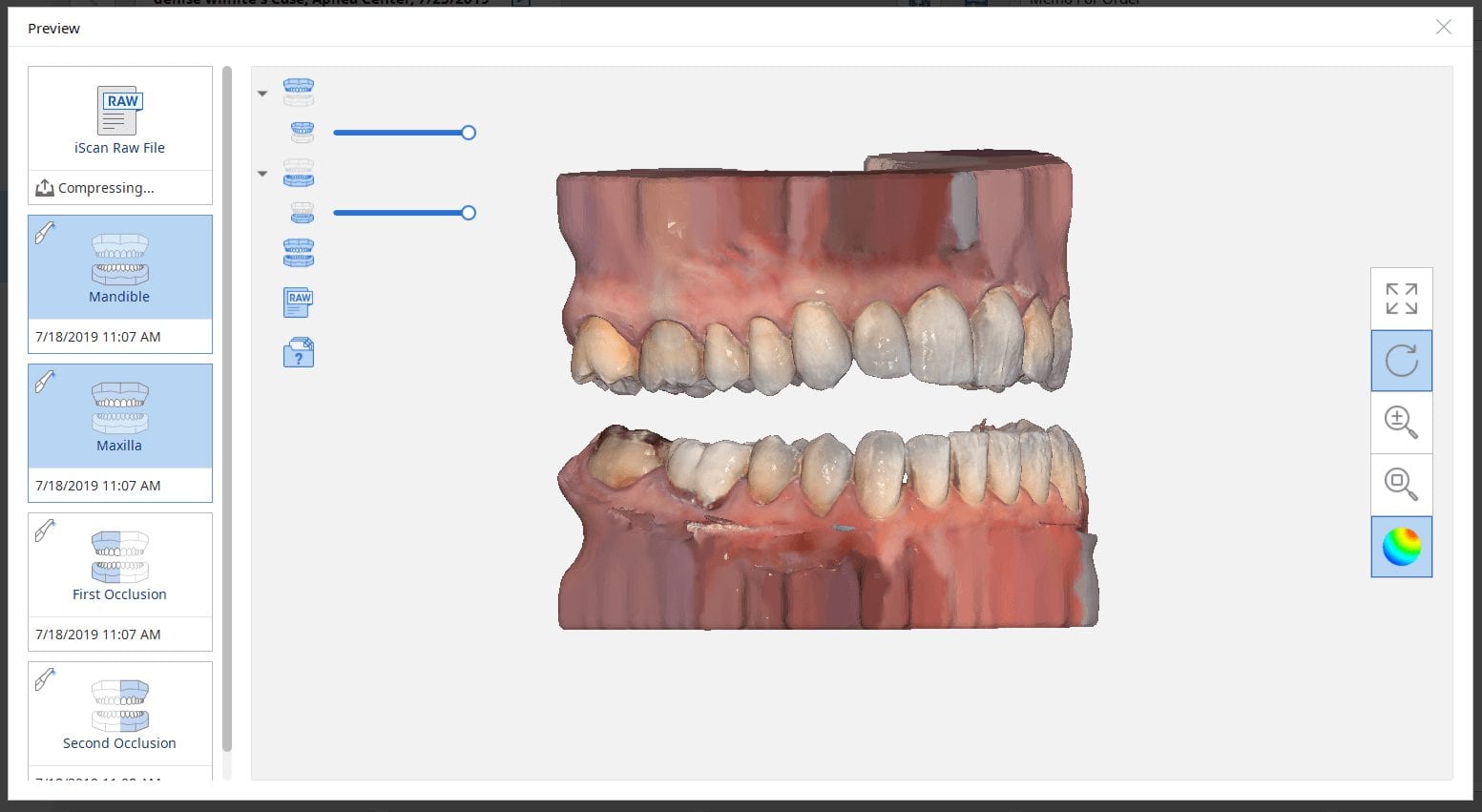

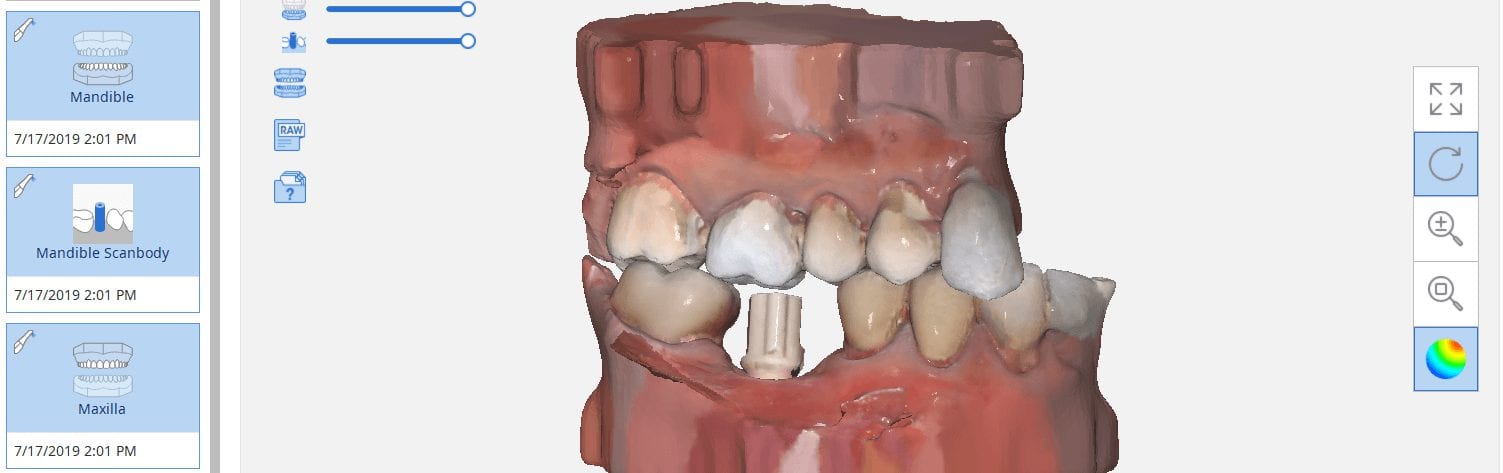

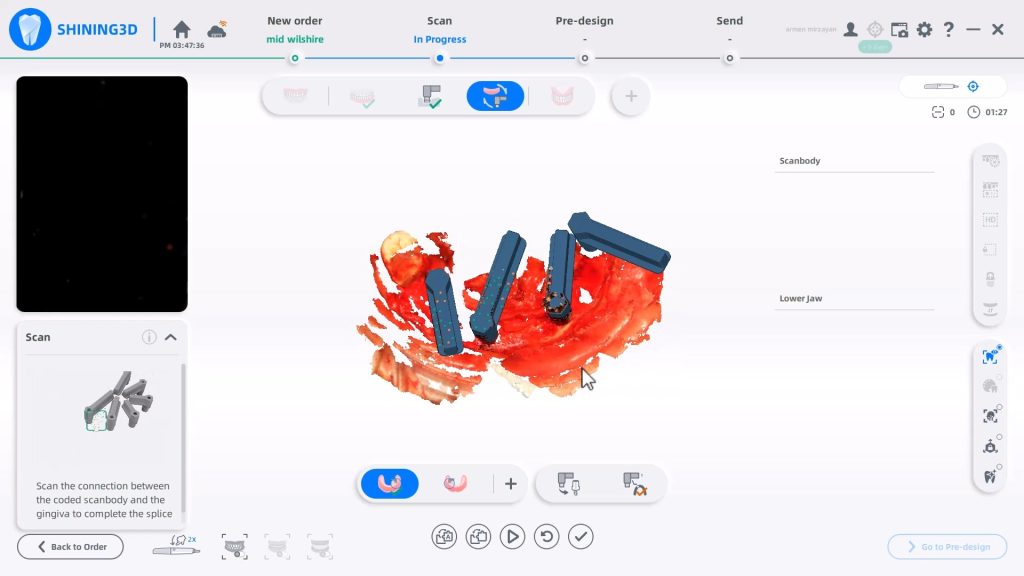

With the Medit i500, after the patient is anesthetized and the area is isolated, the pre-existing crown is imaged in the pre-op catalog box. The area to be prepared is cropped out in anticipation of the imaging the modified preparation.

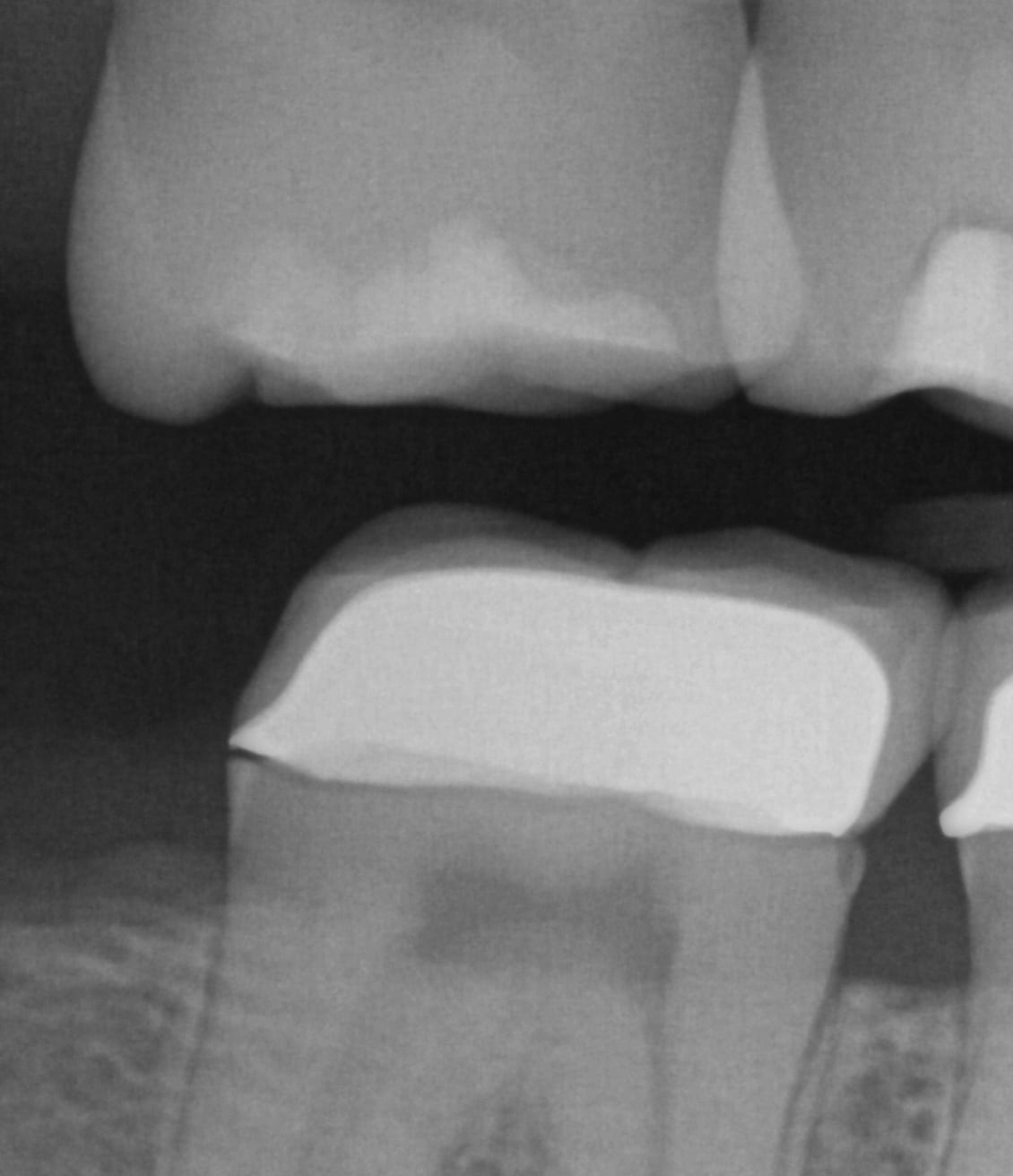

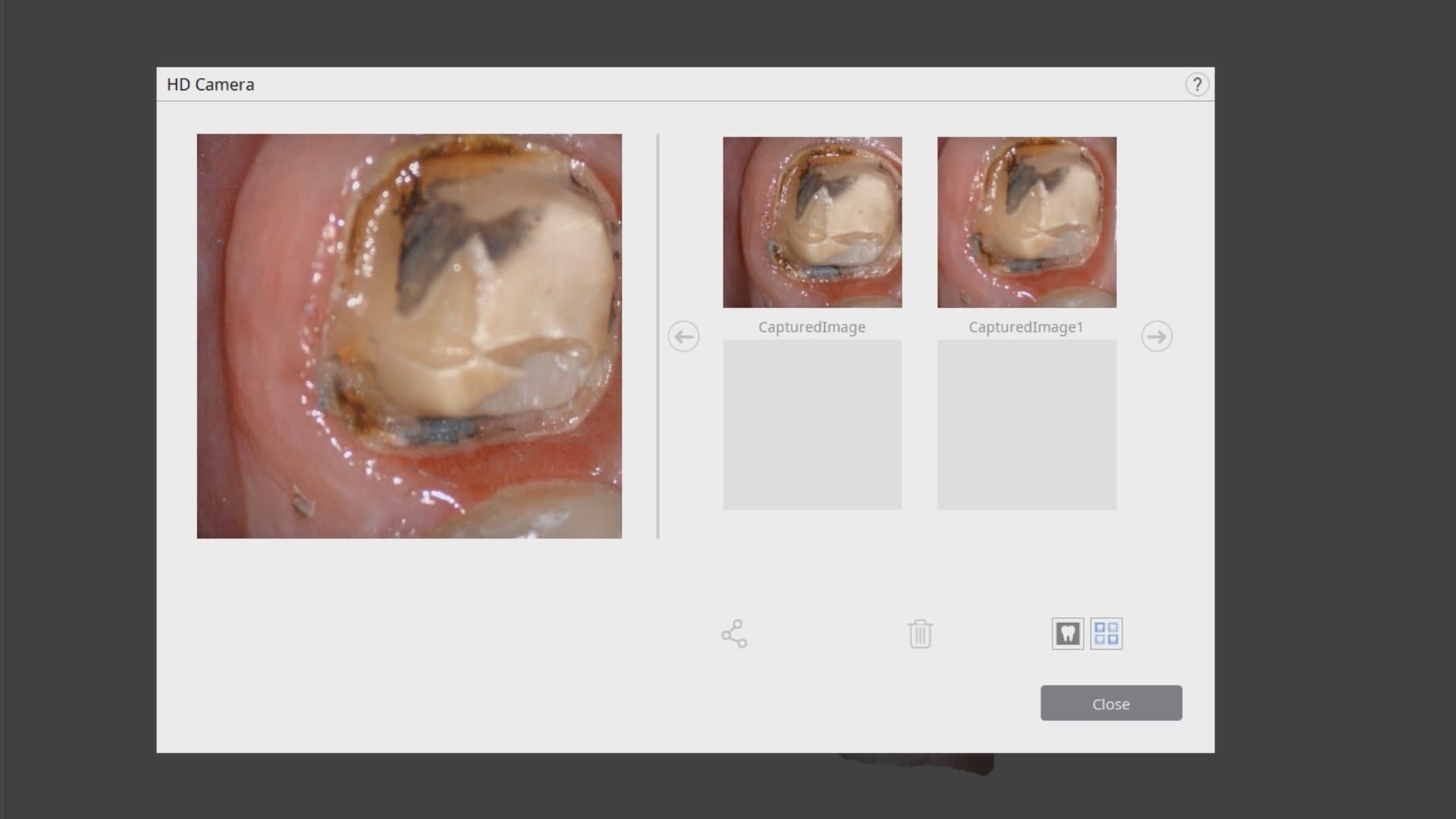

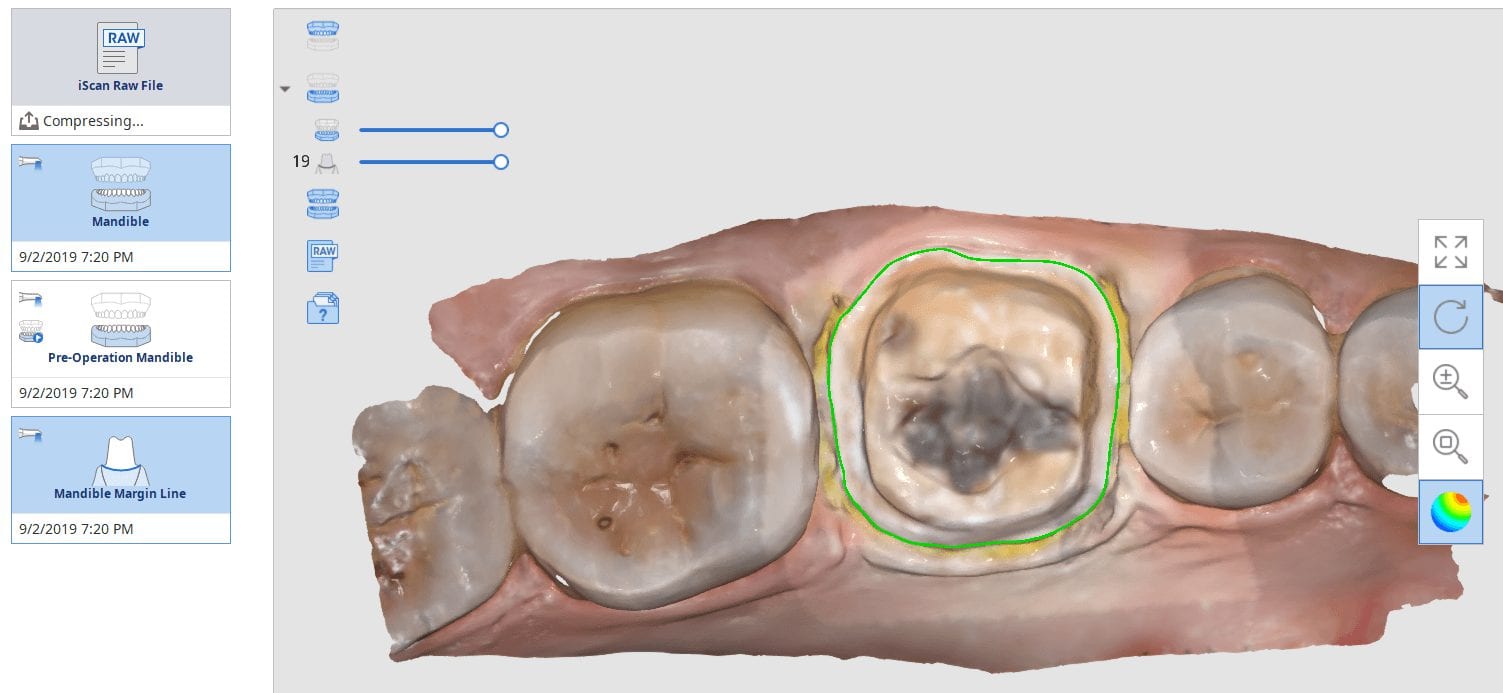

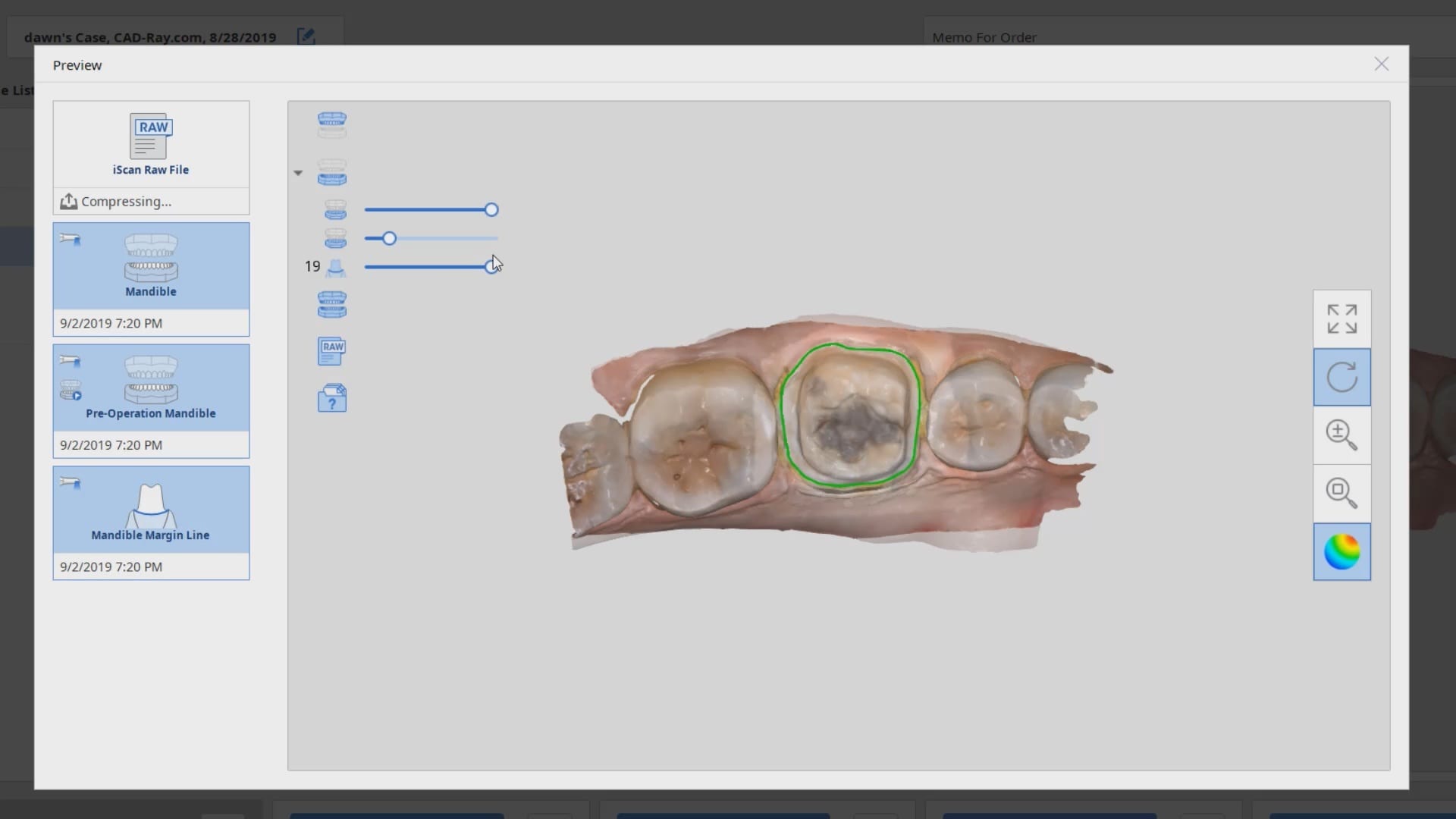

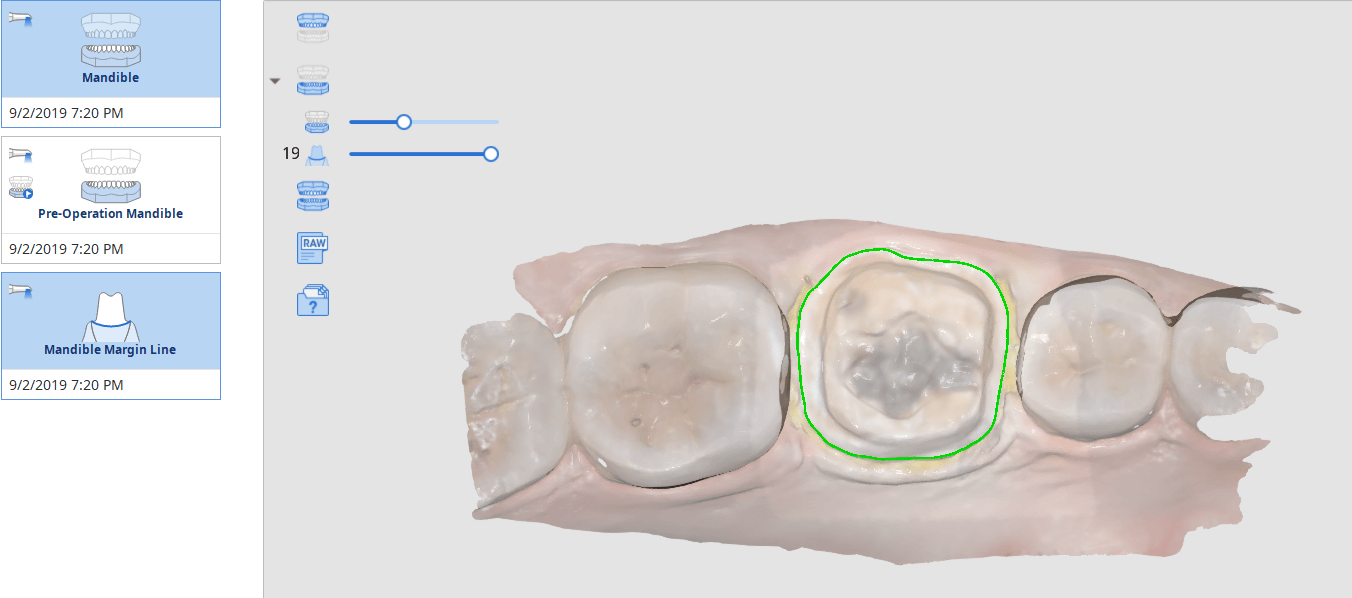

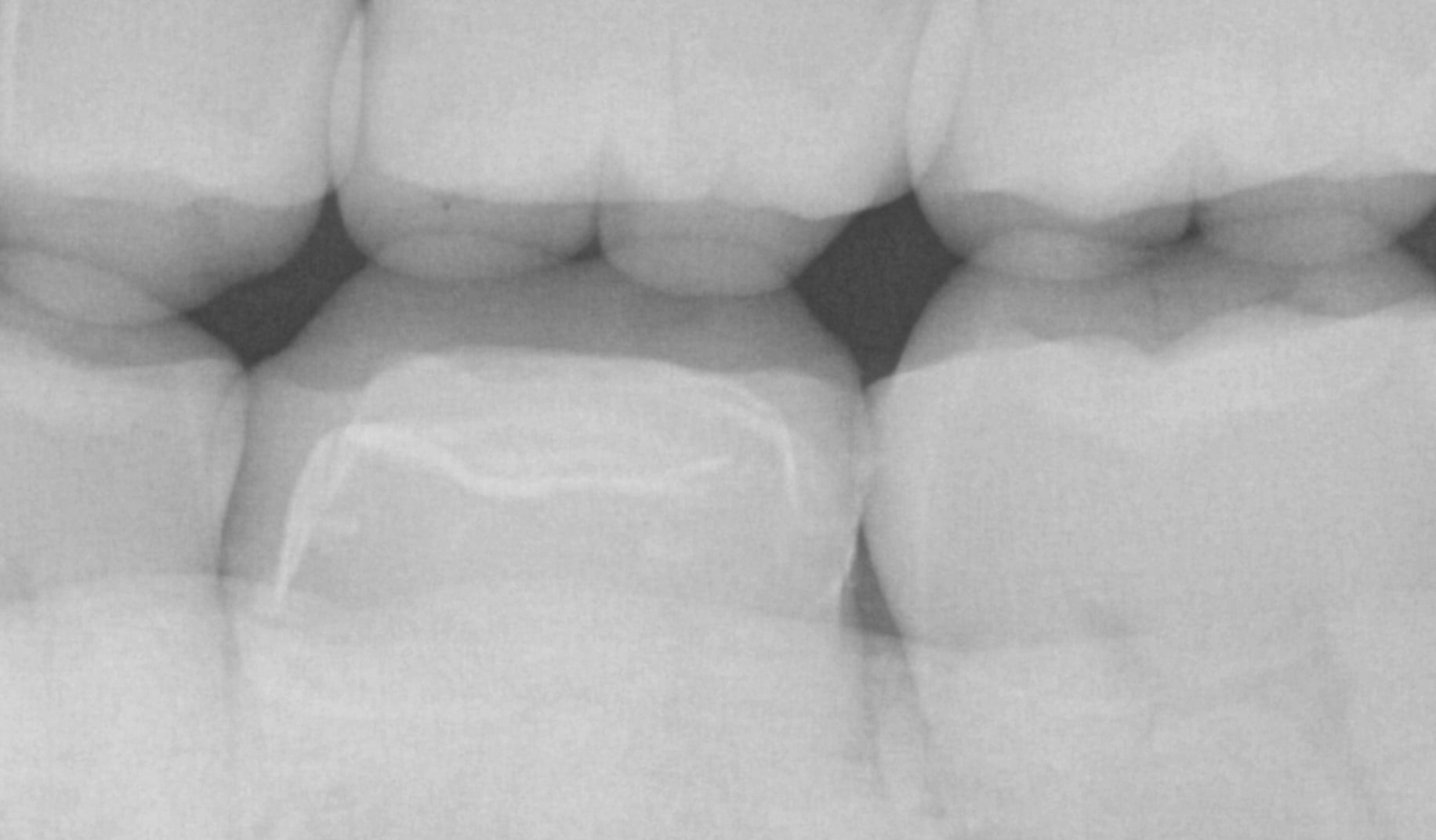

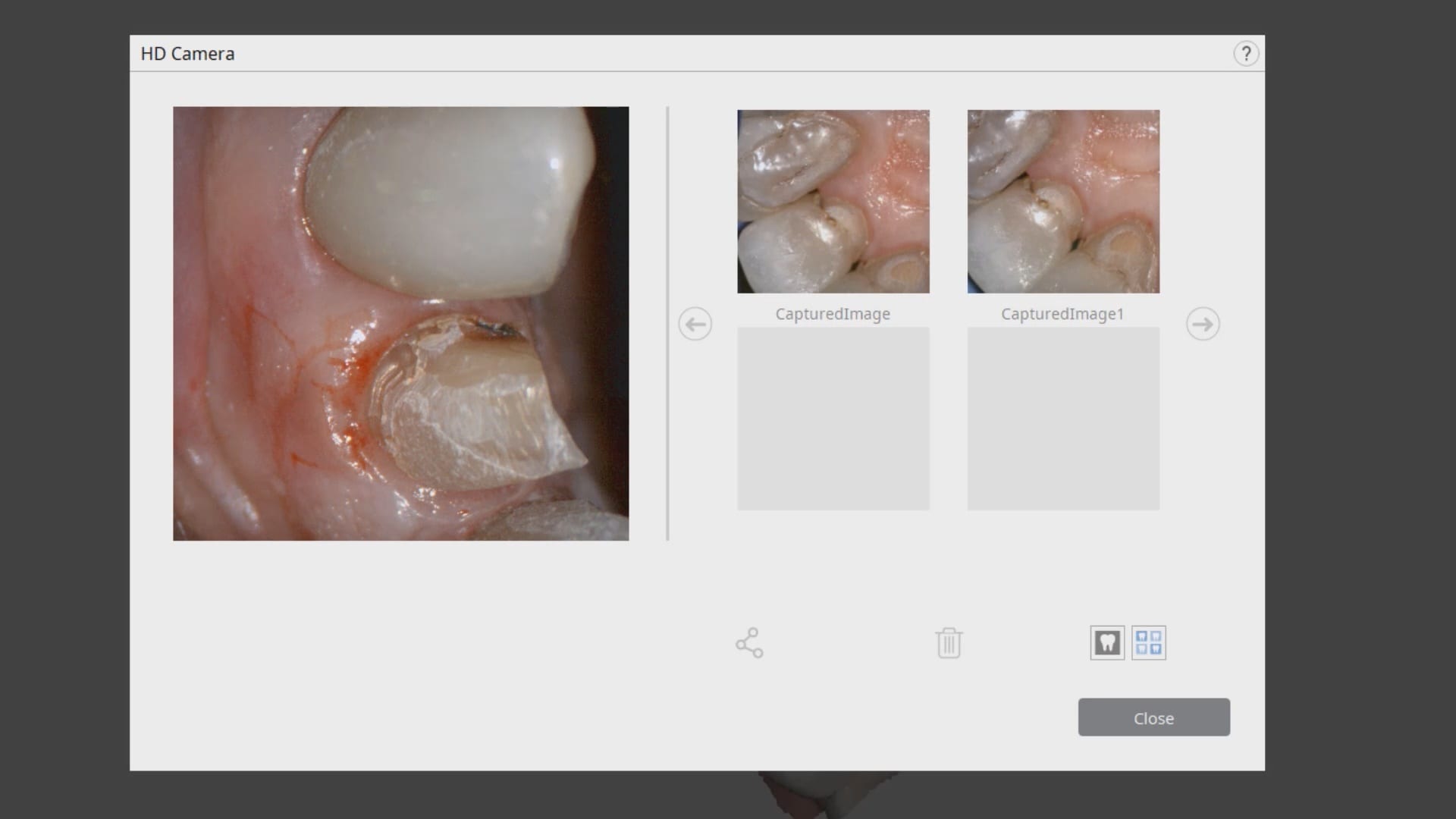

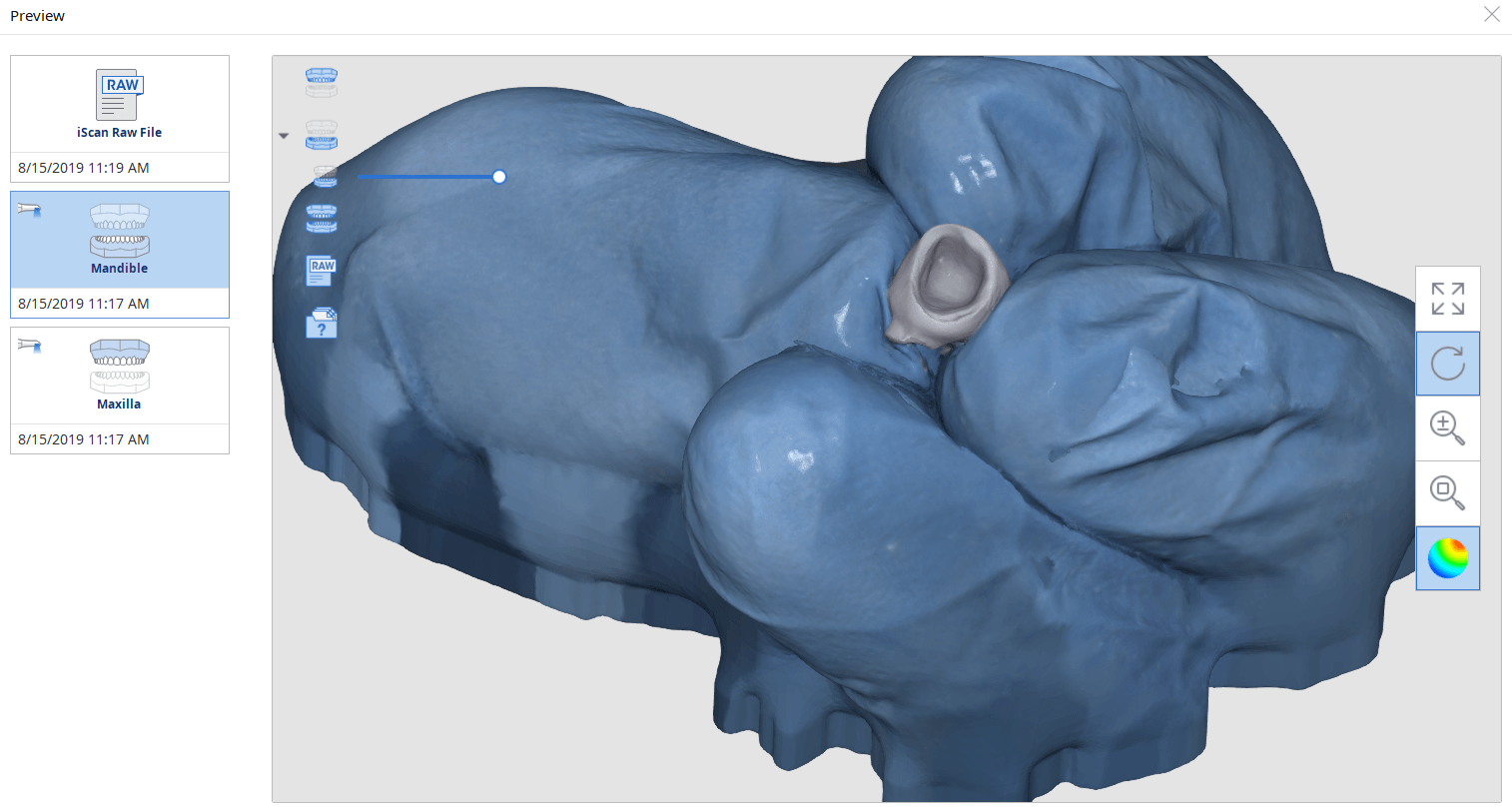

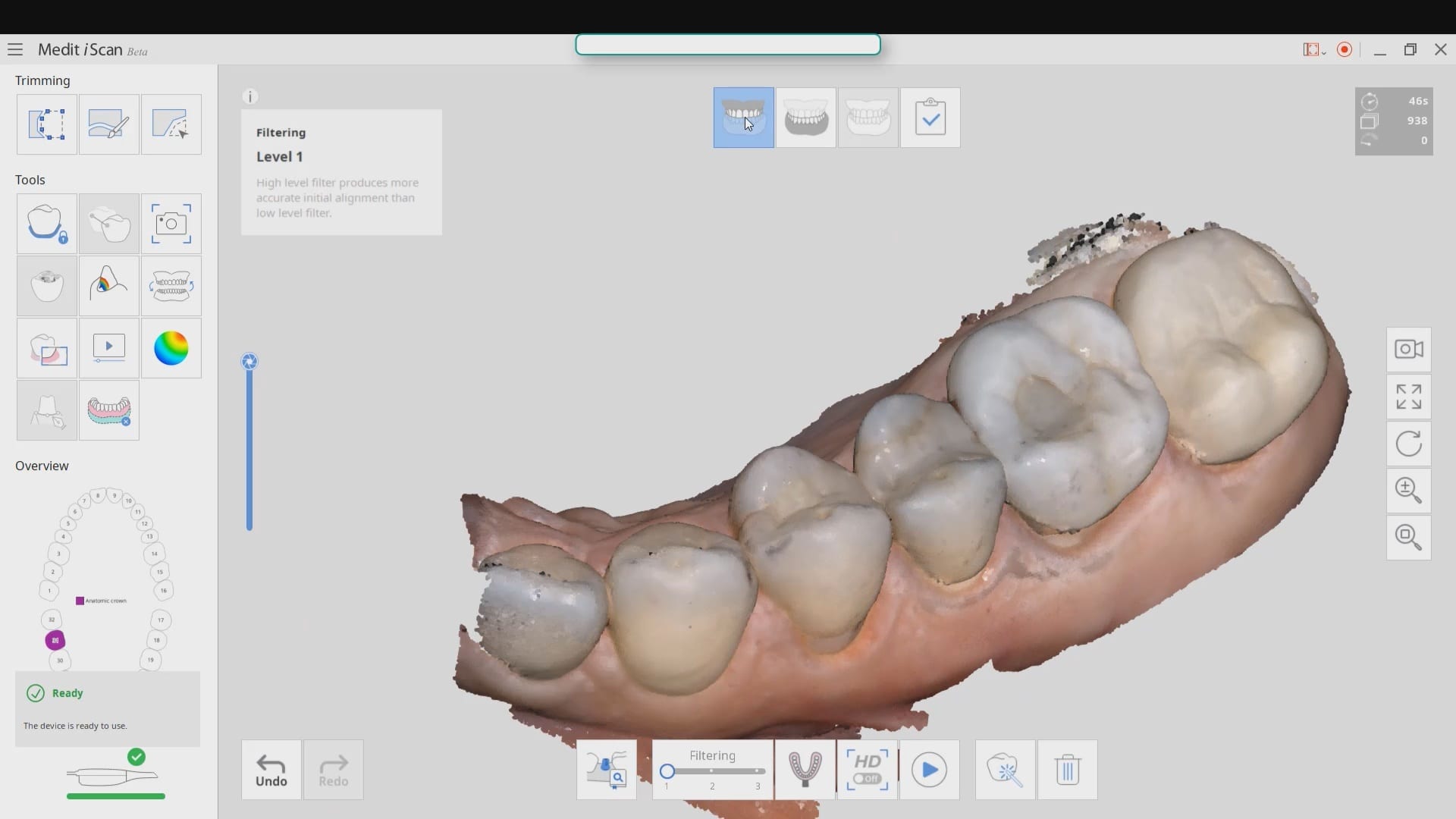

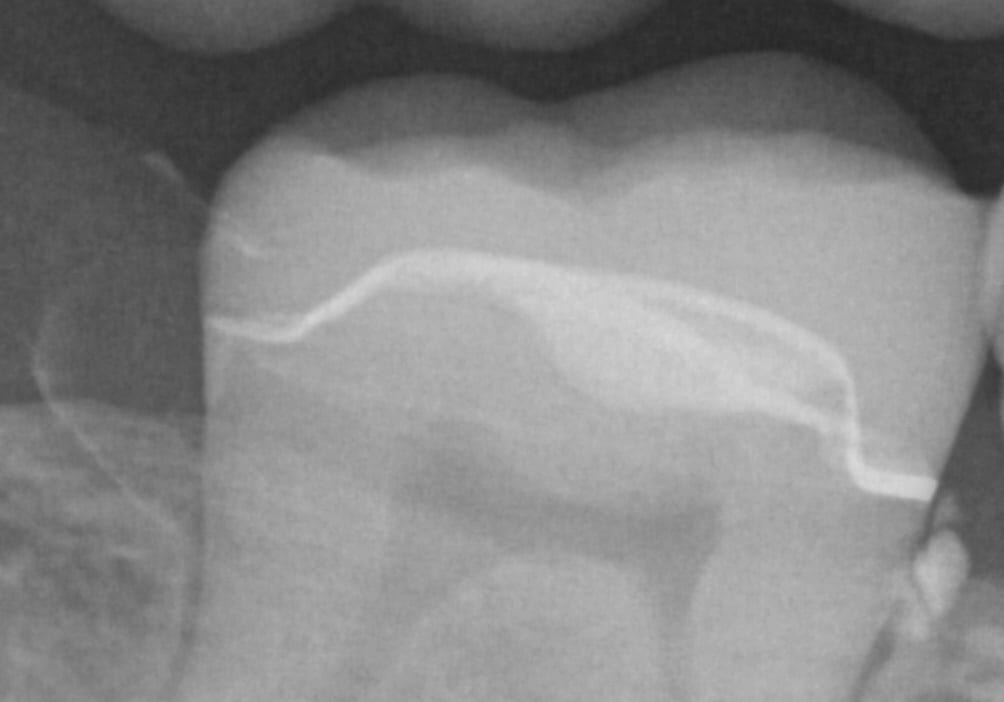

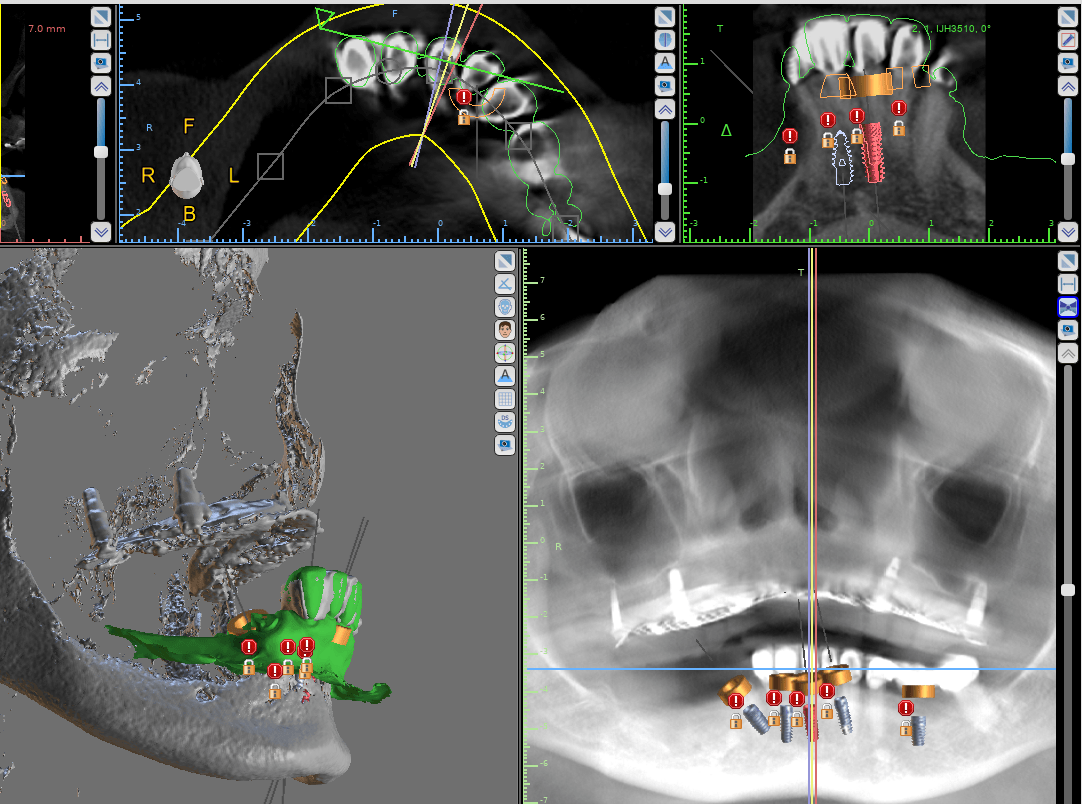

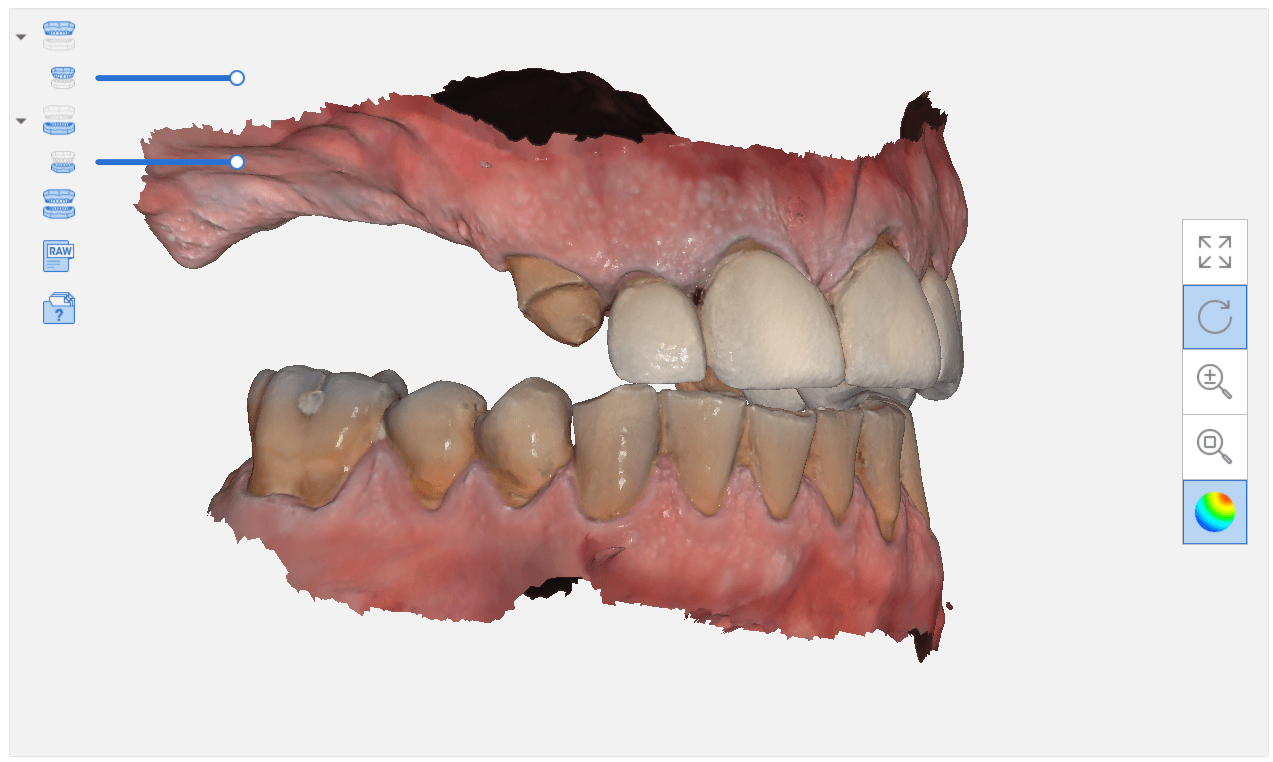

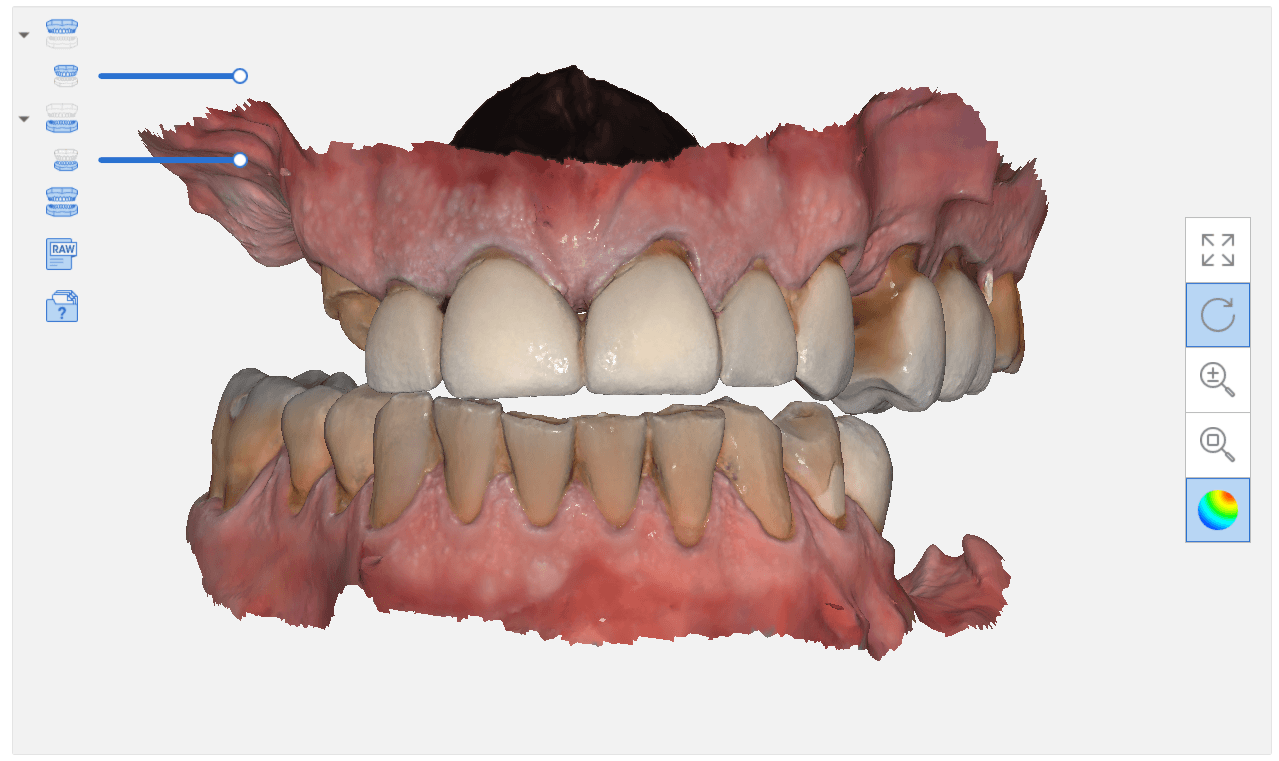

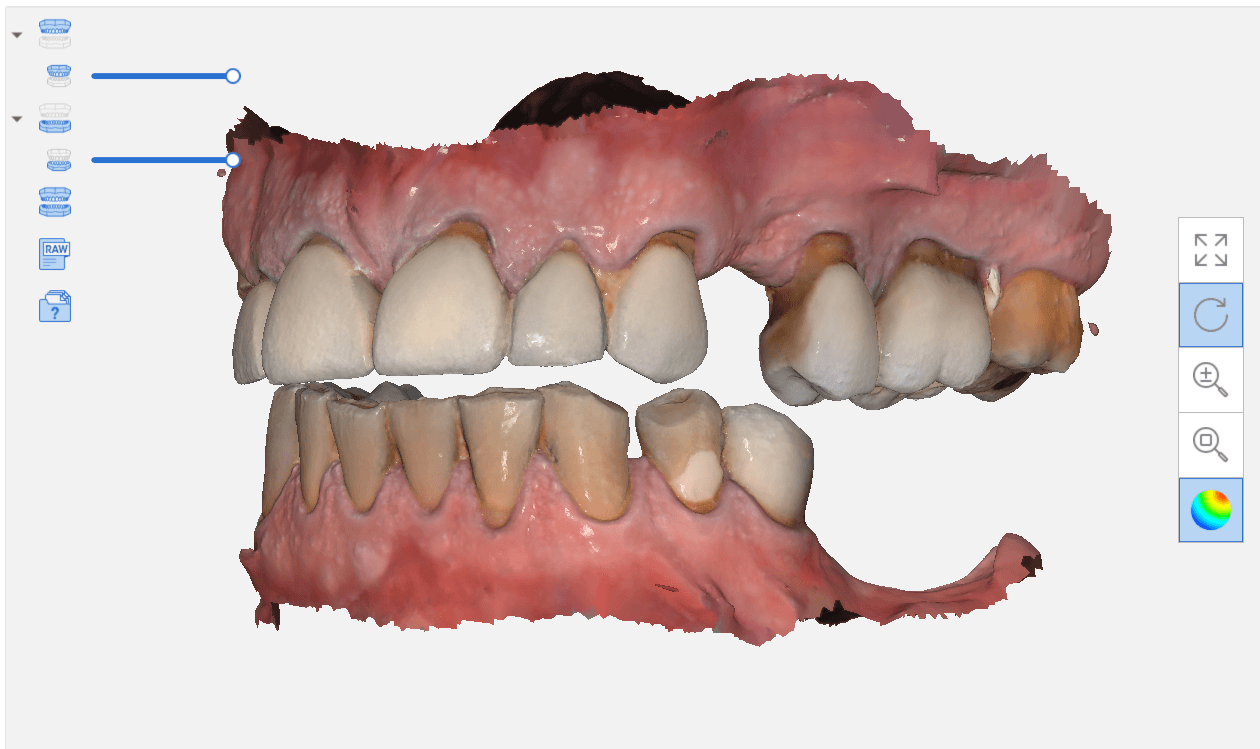

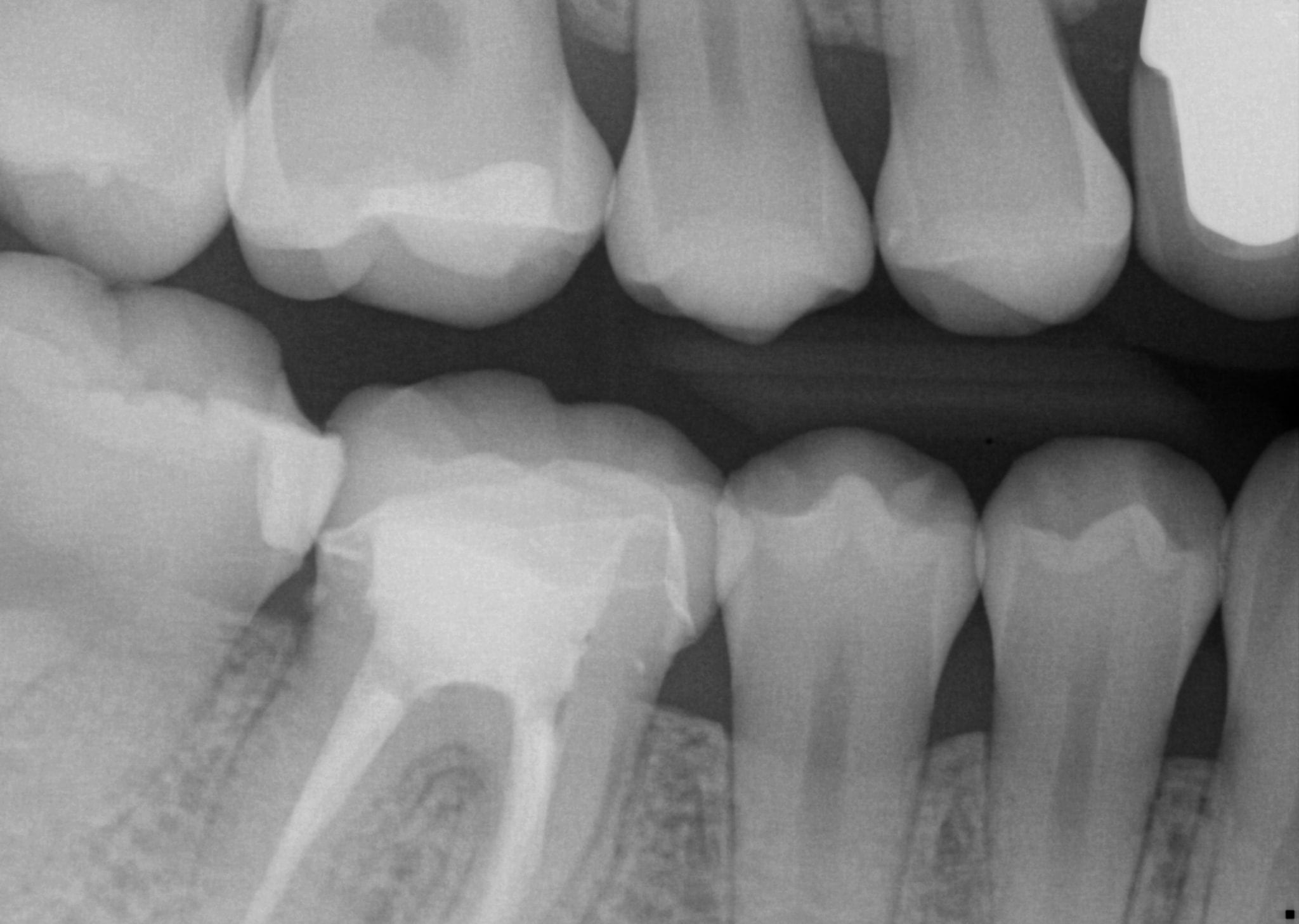

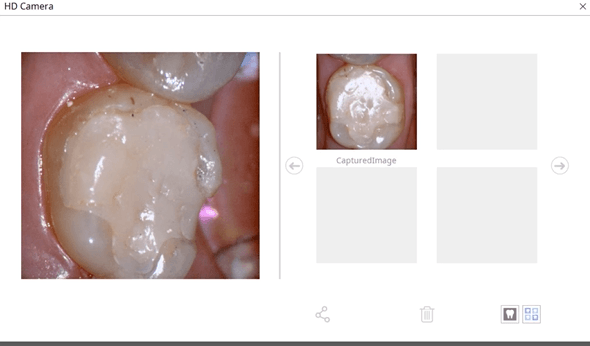

Once the crown is removed, expasyl is packed into the sulcus with a Number 2 cord. With the pre-op bitewings X-ray it was readily apparent that the tissue should be positively displaced in order to capture the margins. It took two layers of cord to achieve hemostasis for imaging with the Medit i500.

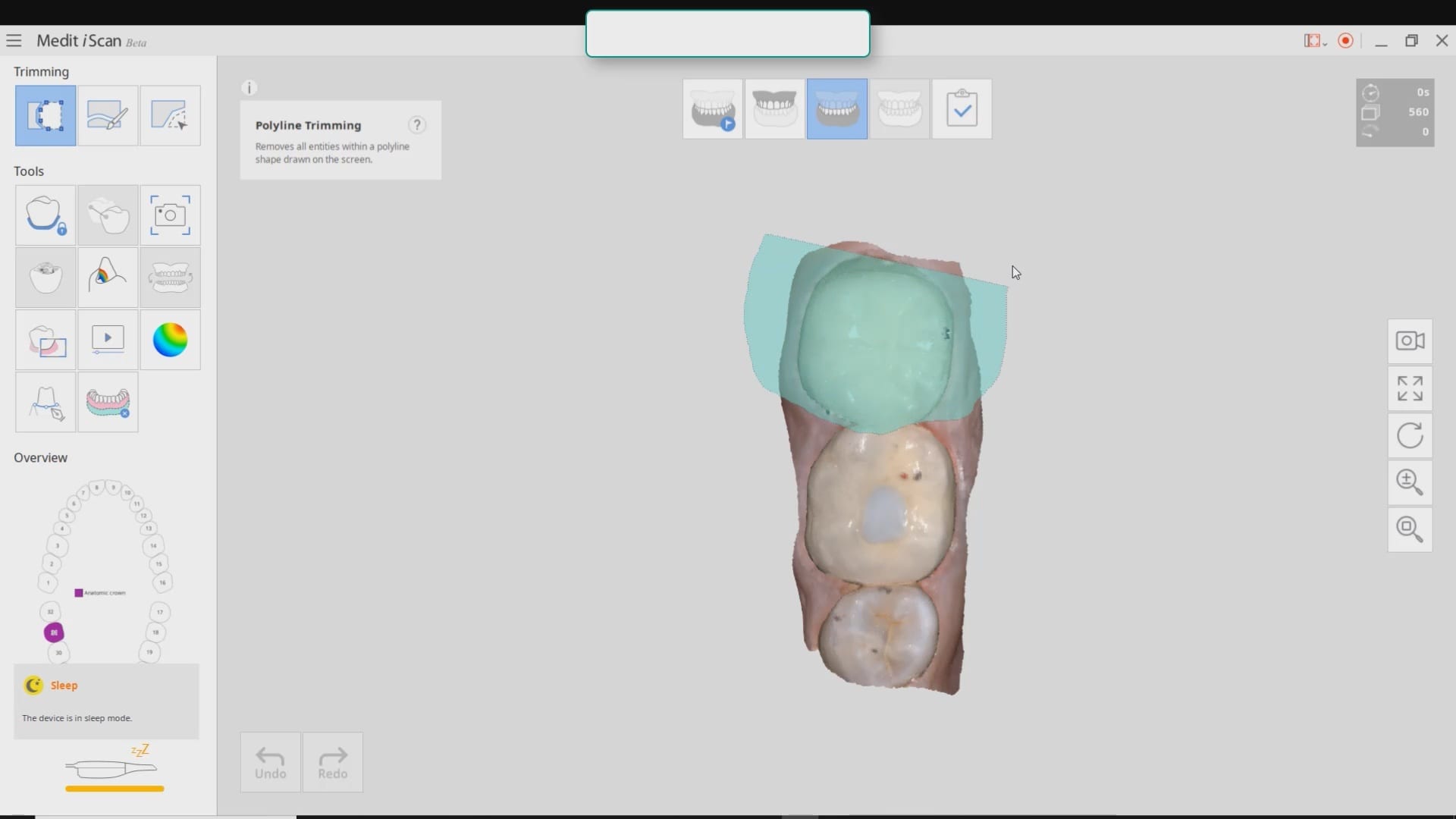

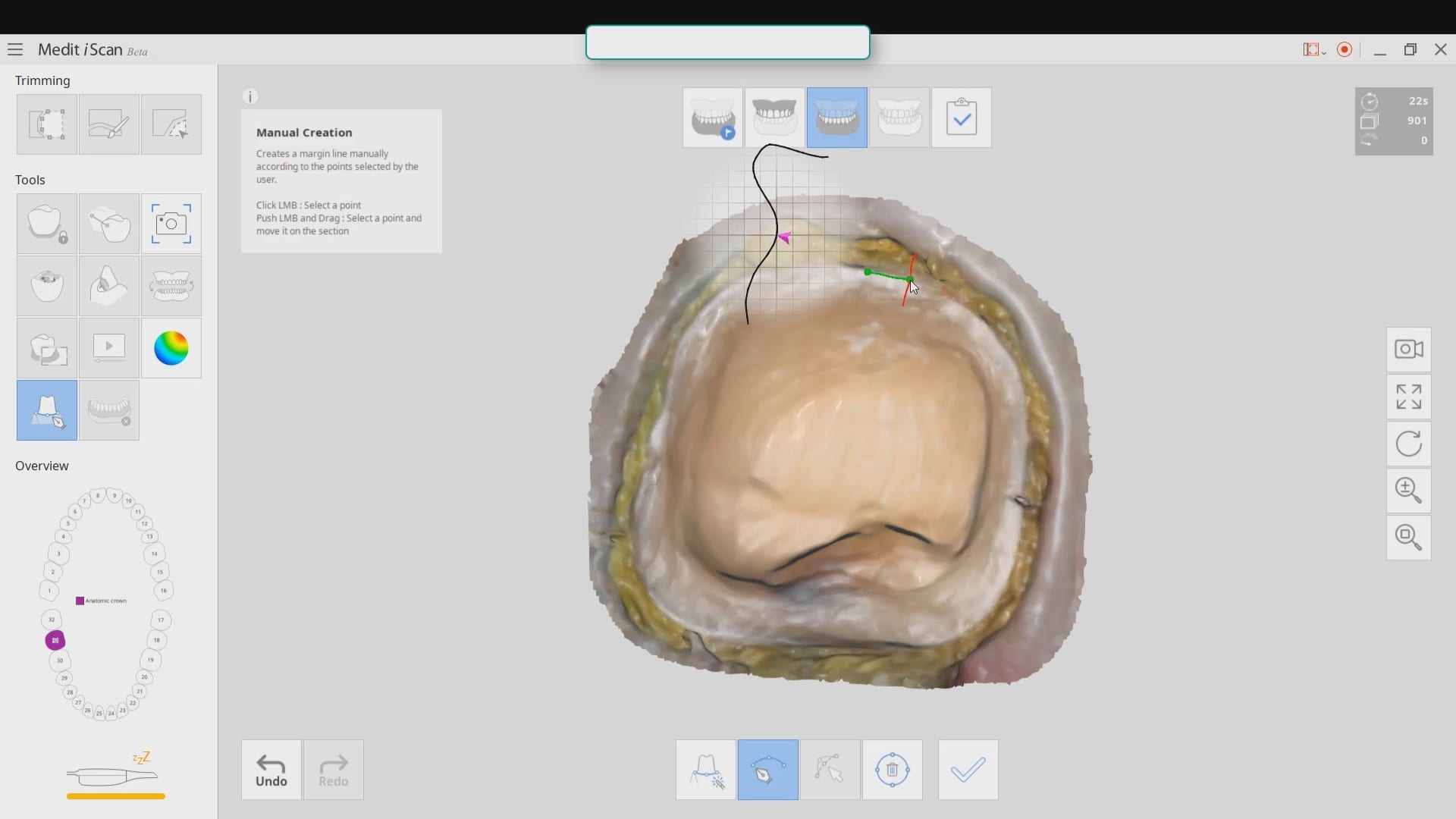

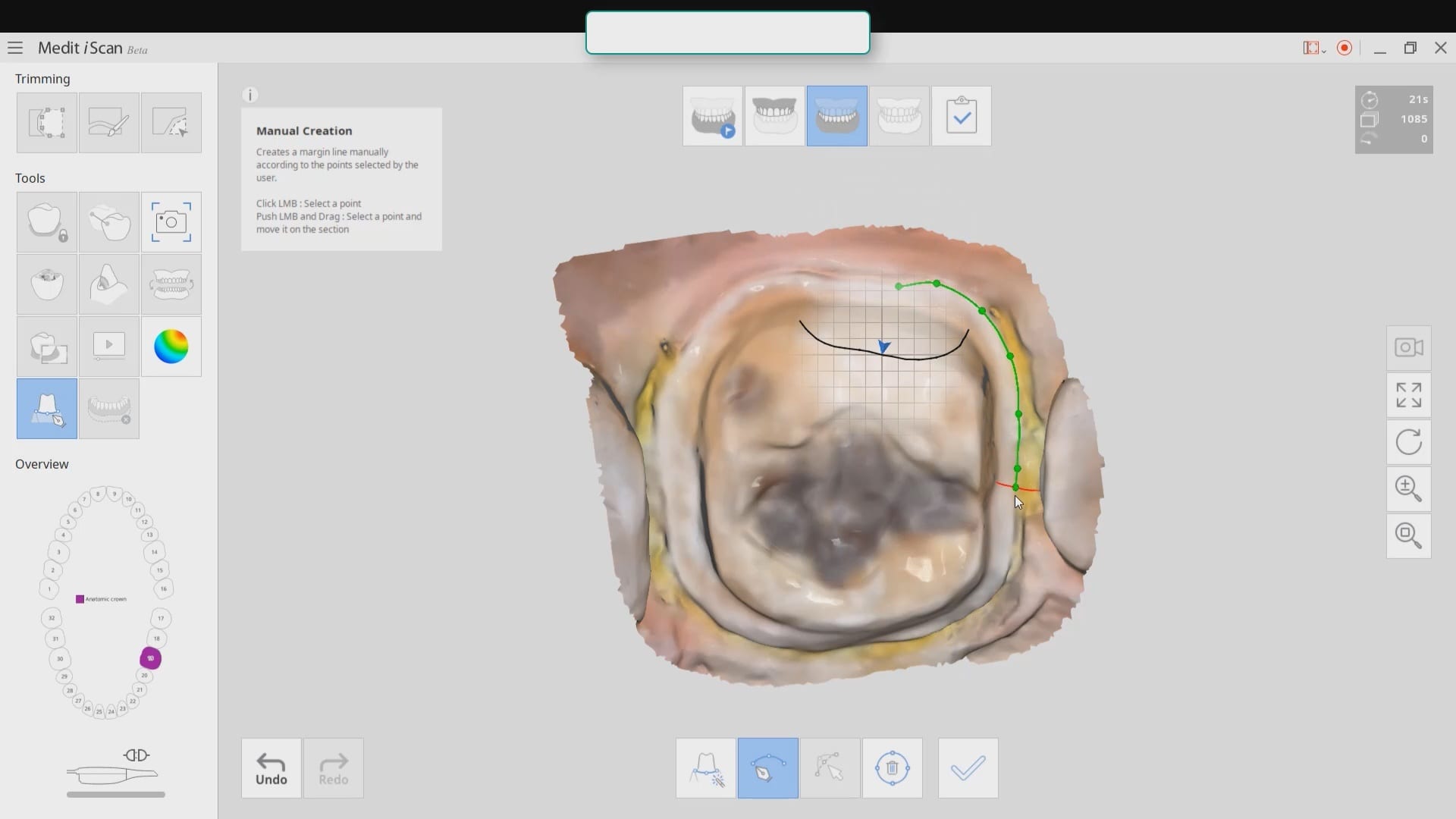

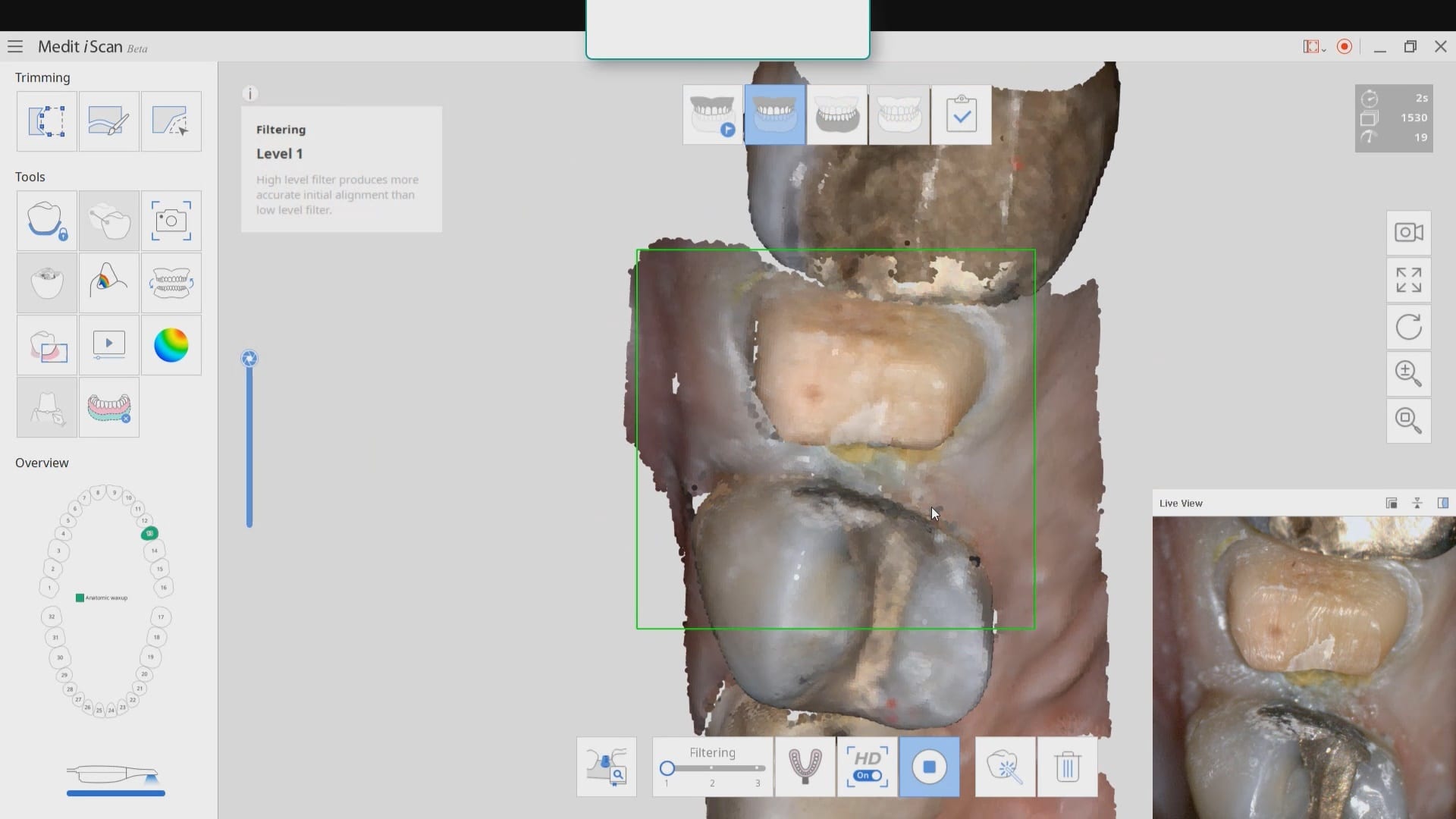

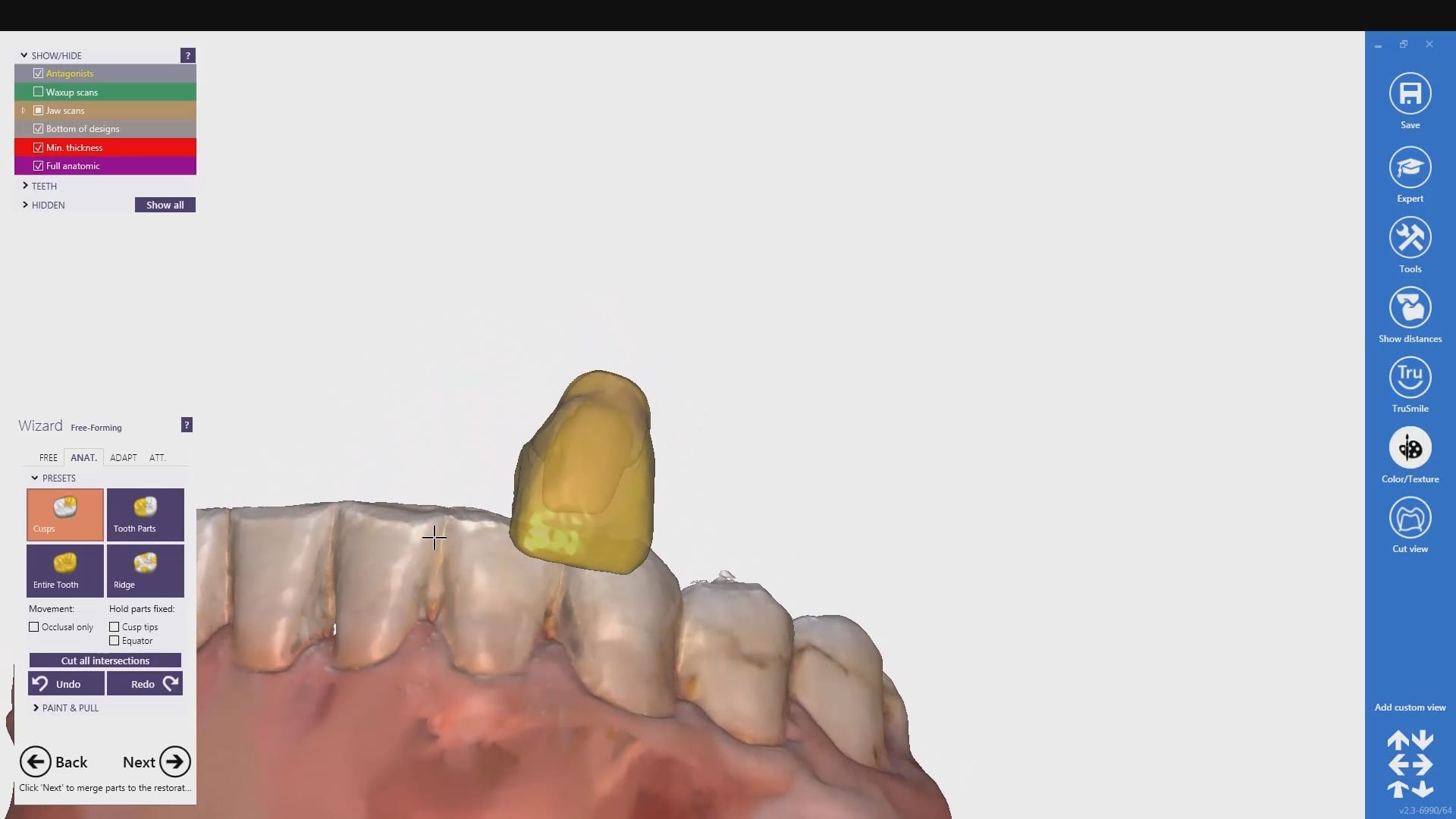

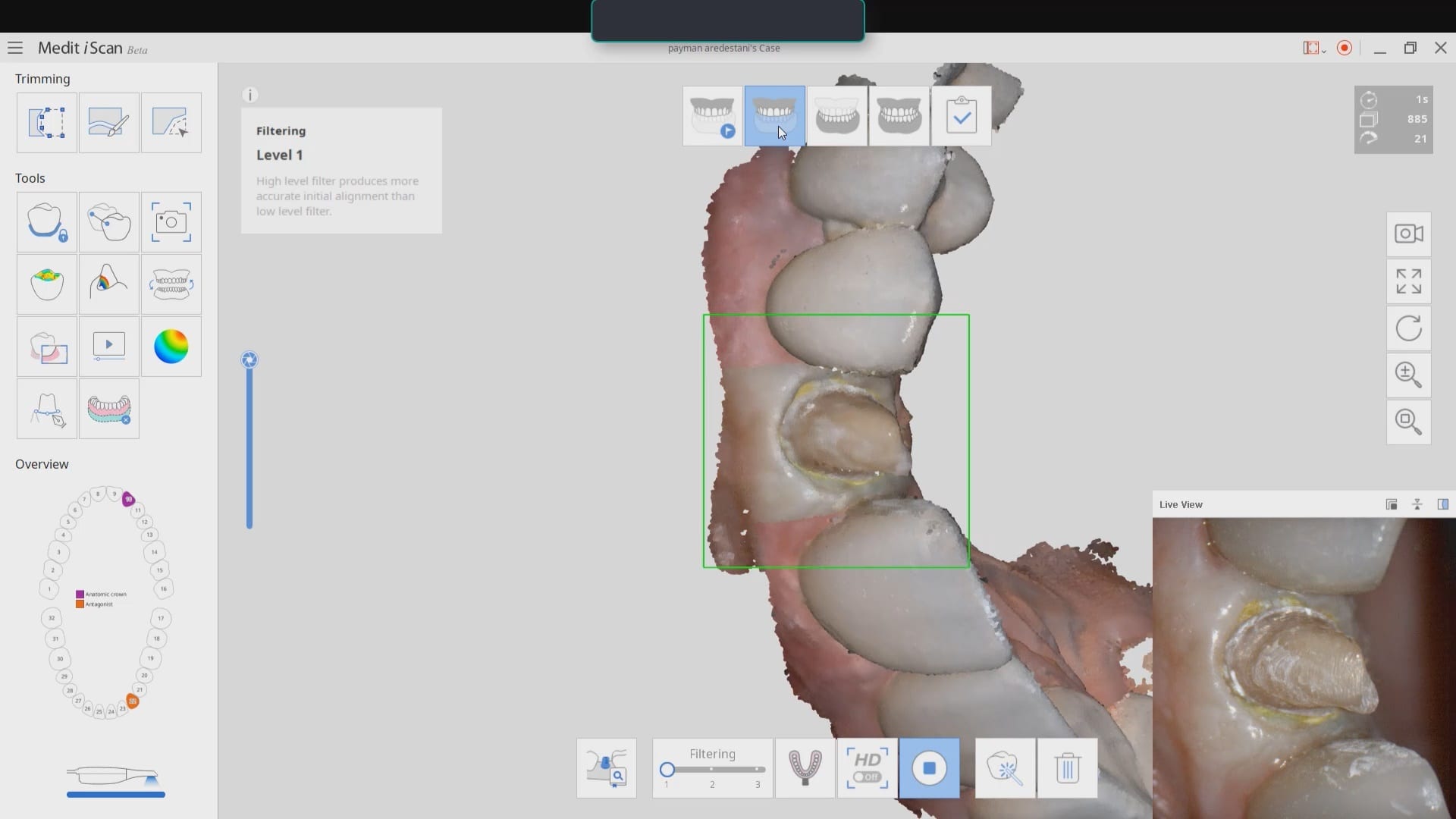

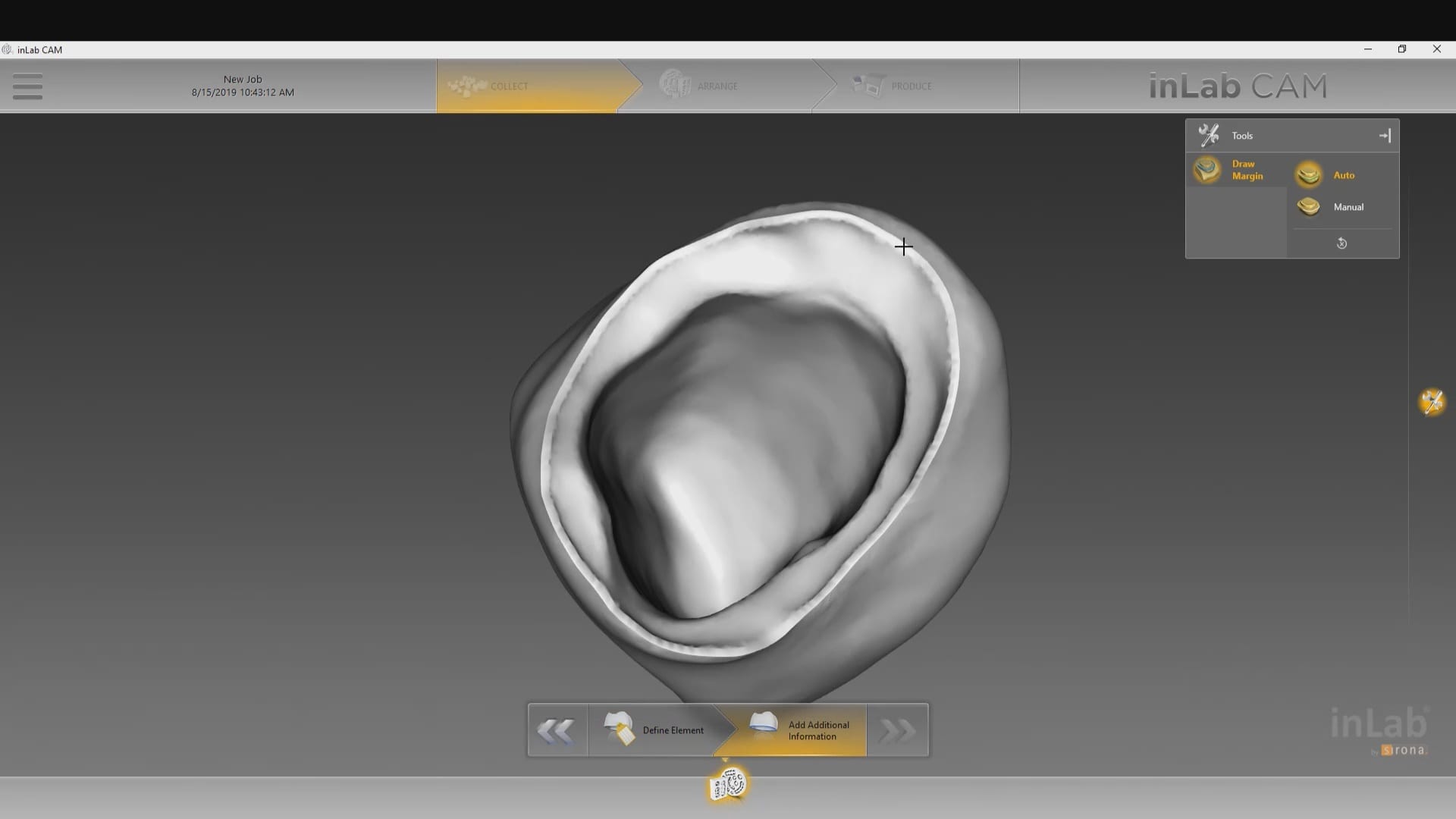

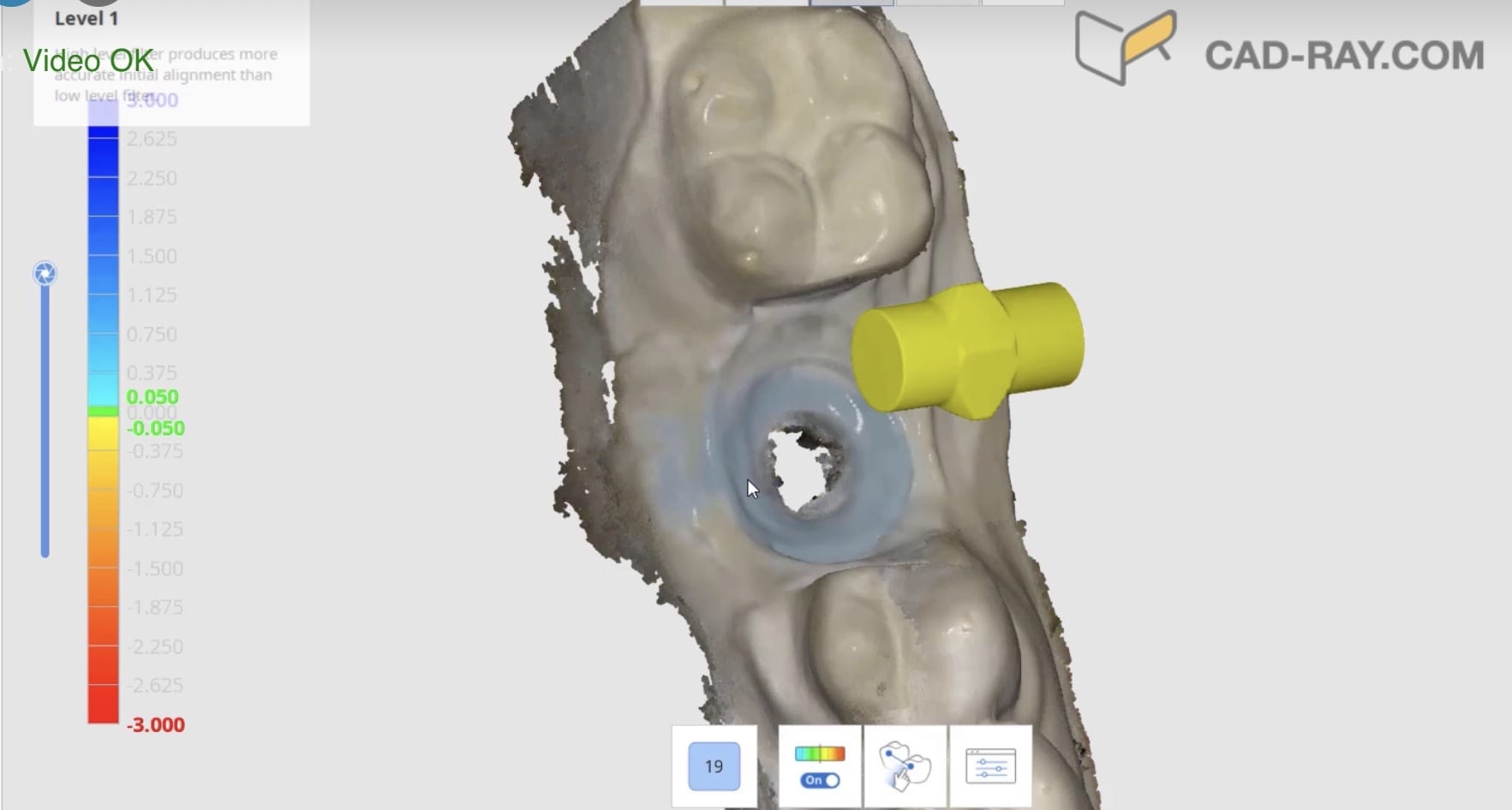

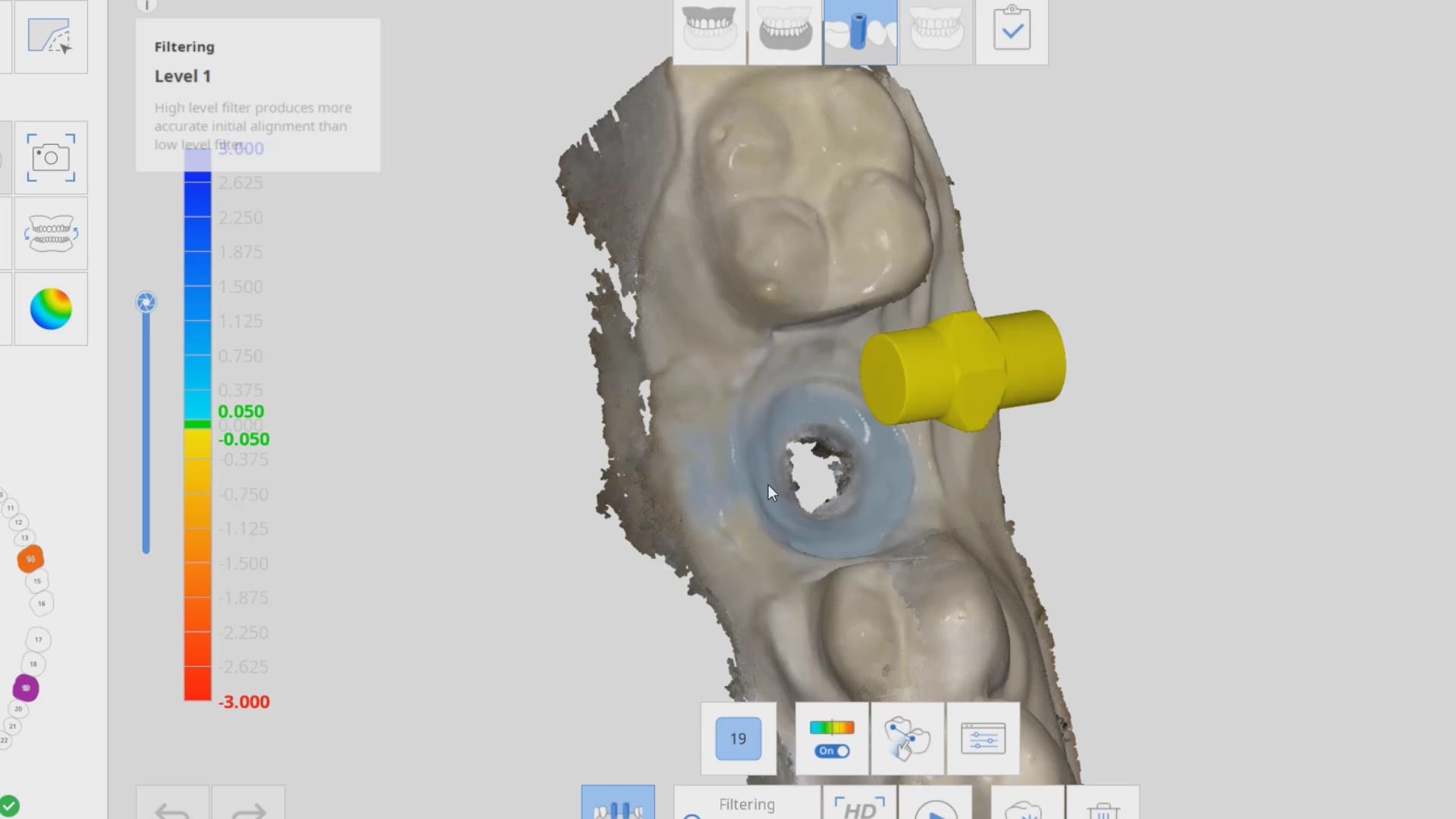

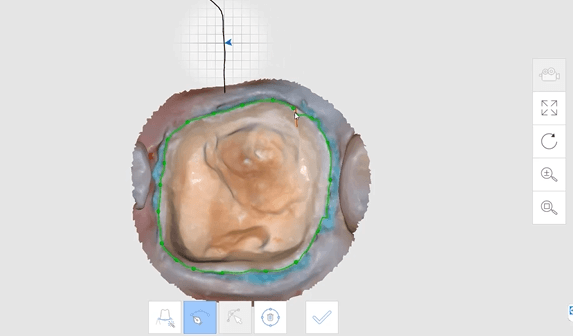

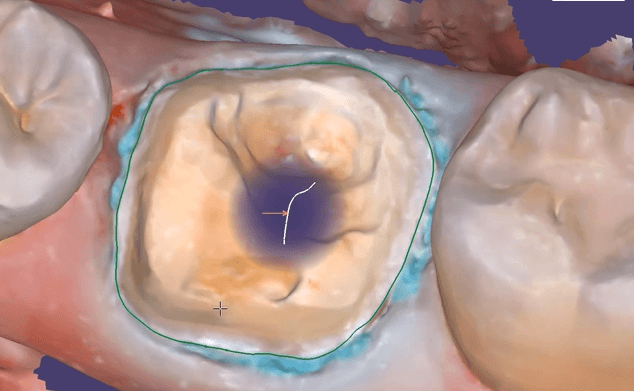

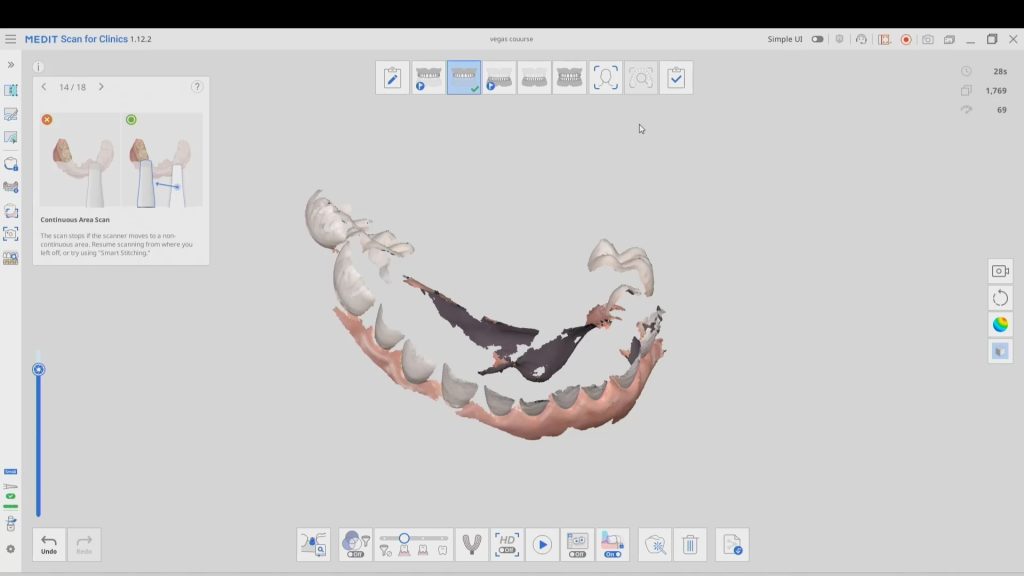

While placing the margin in the native imaging software, it was noted that some tissue was obscuring the margin on the lingual side. The area was isolated both clinically and in the software. It was cropped out and filled in with ‘good data’ after proper protection of the adjacent teeth and margins so that we did not obscure their geometry.

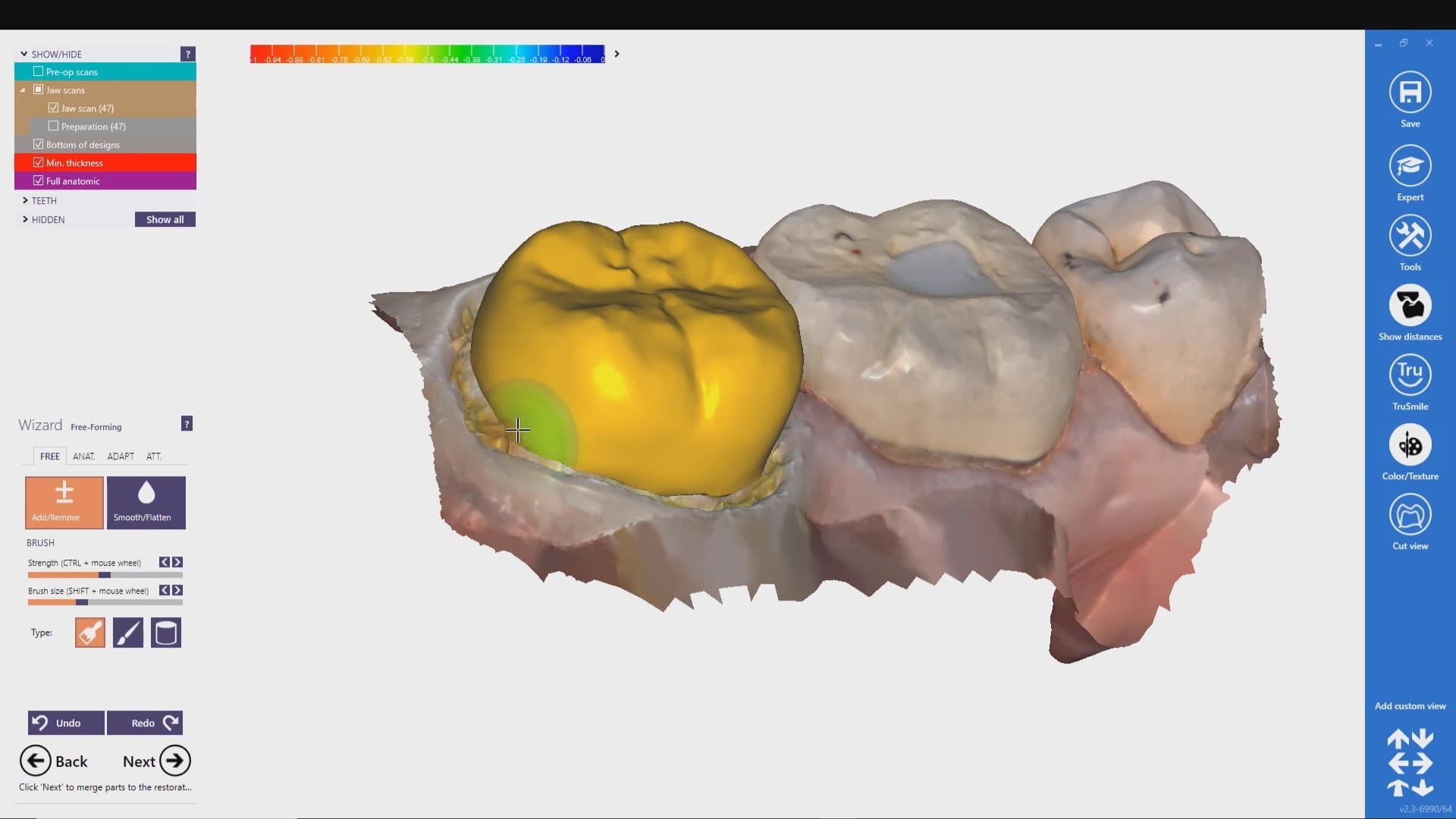

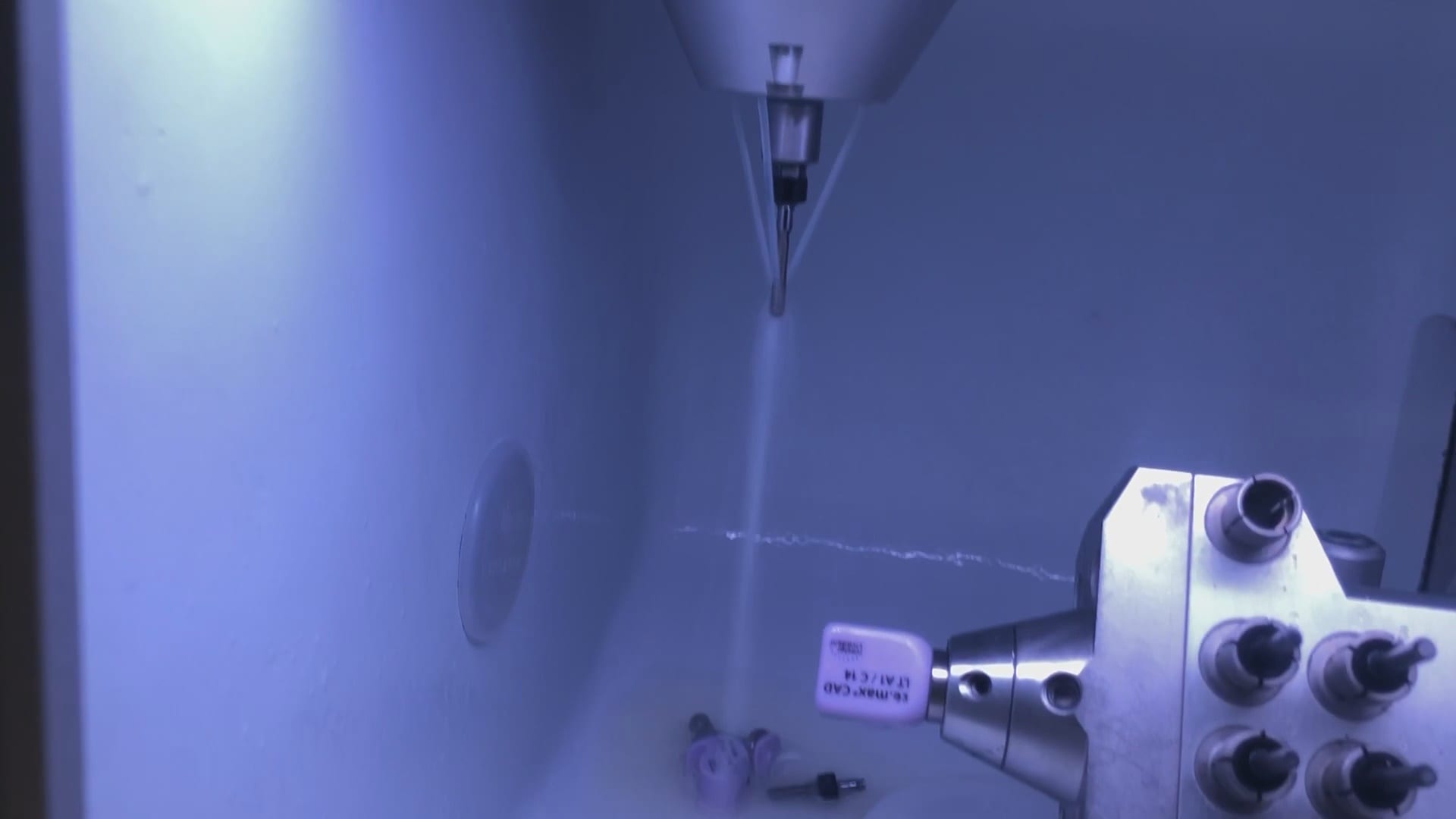

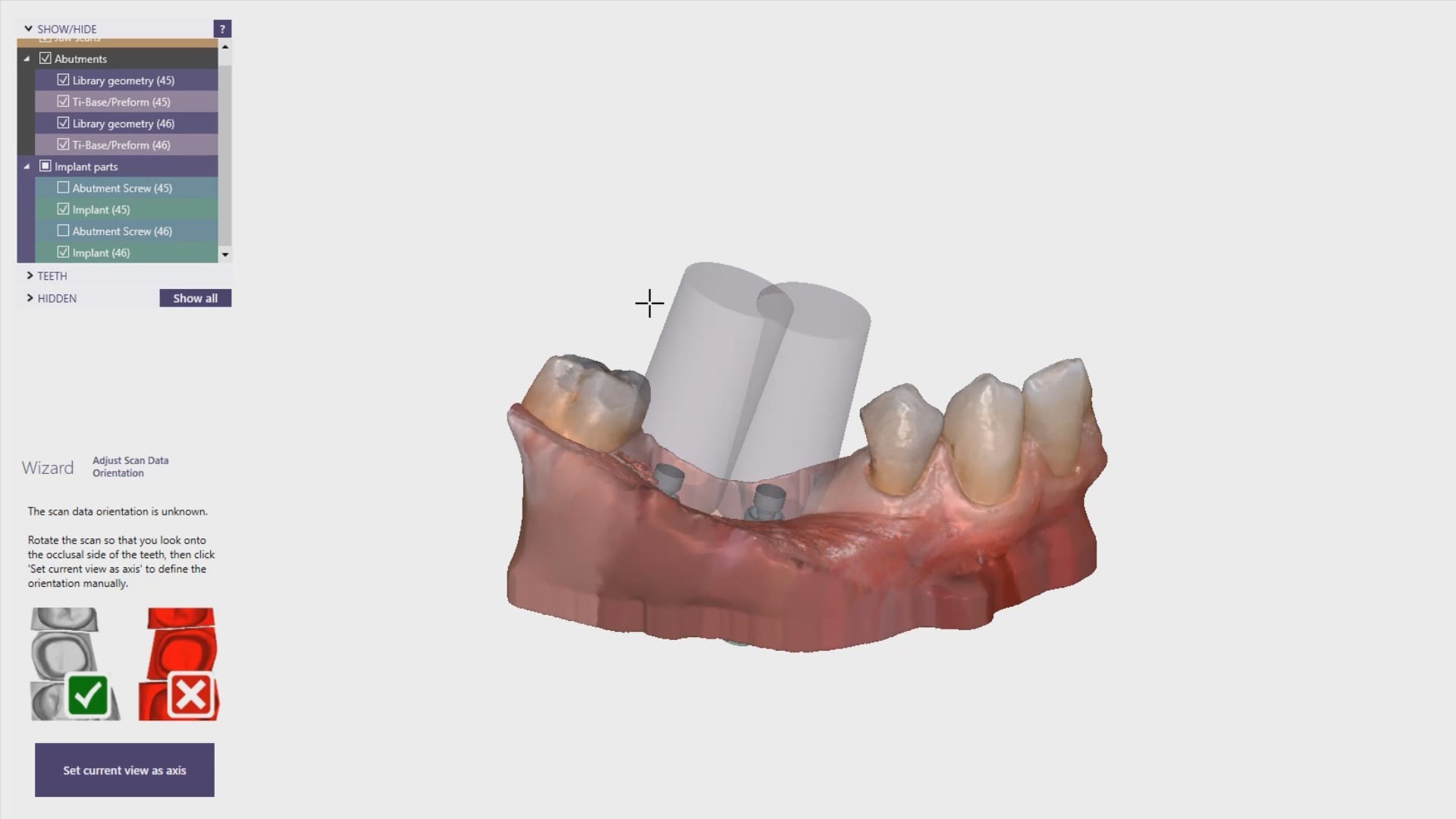

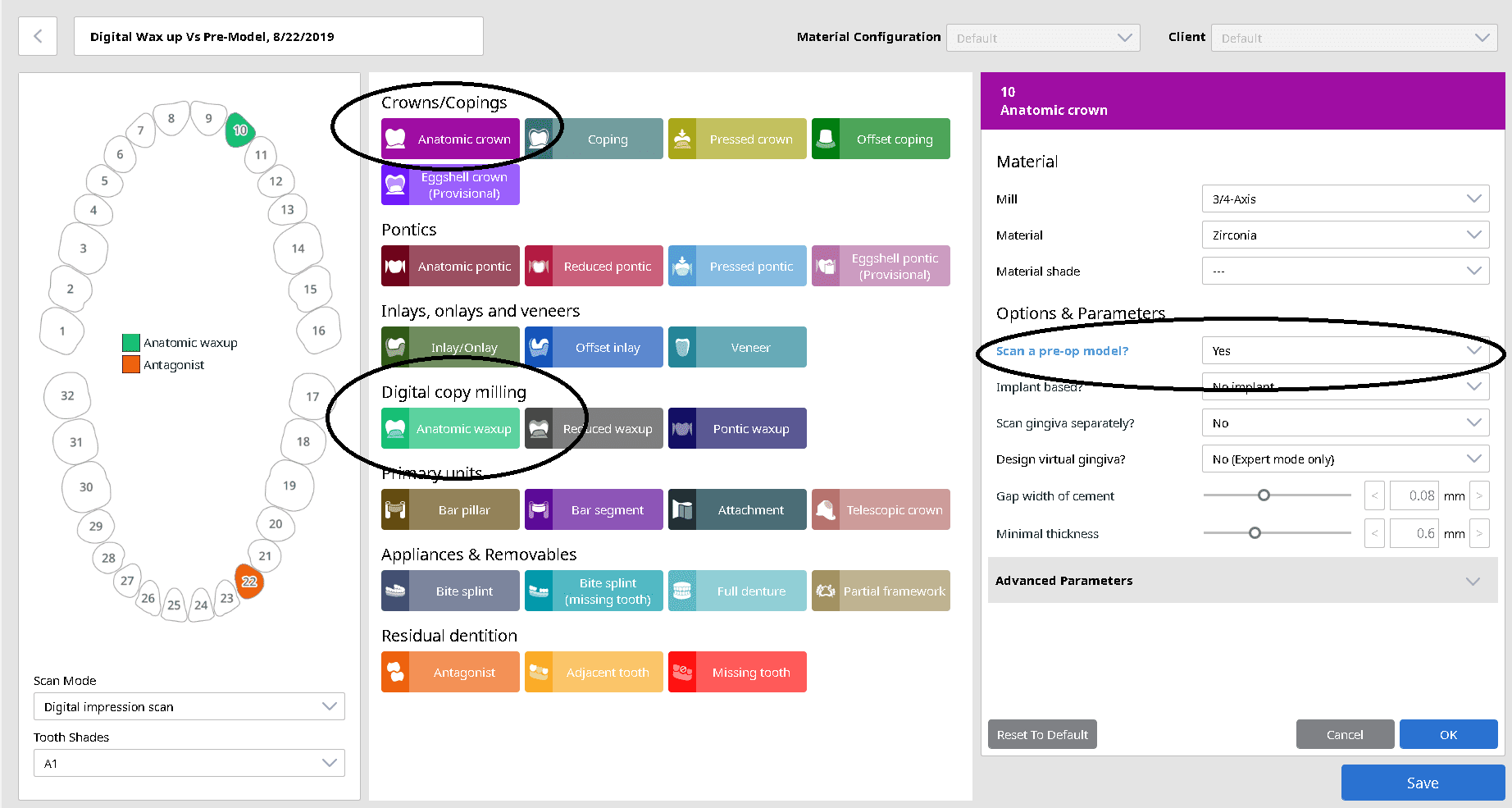

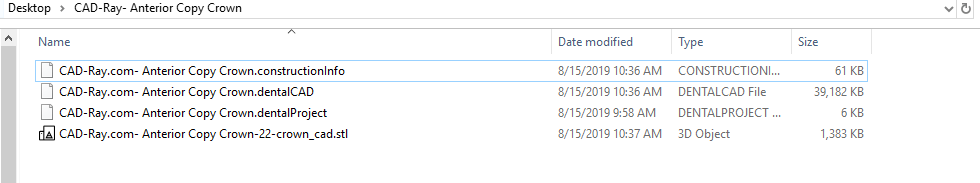

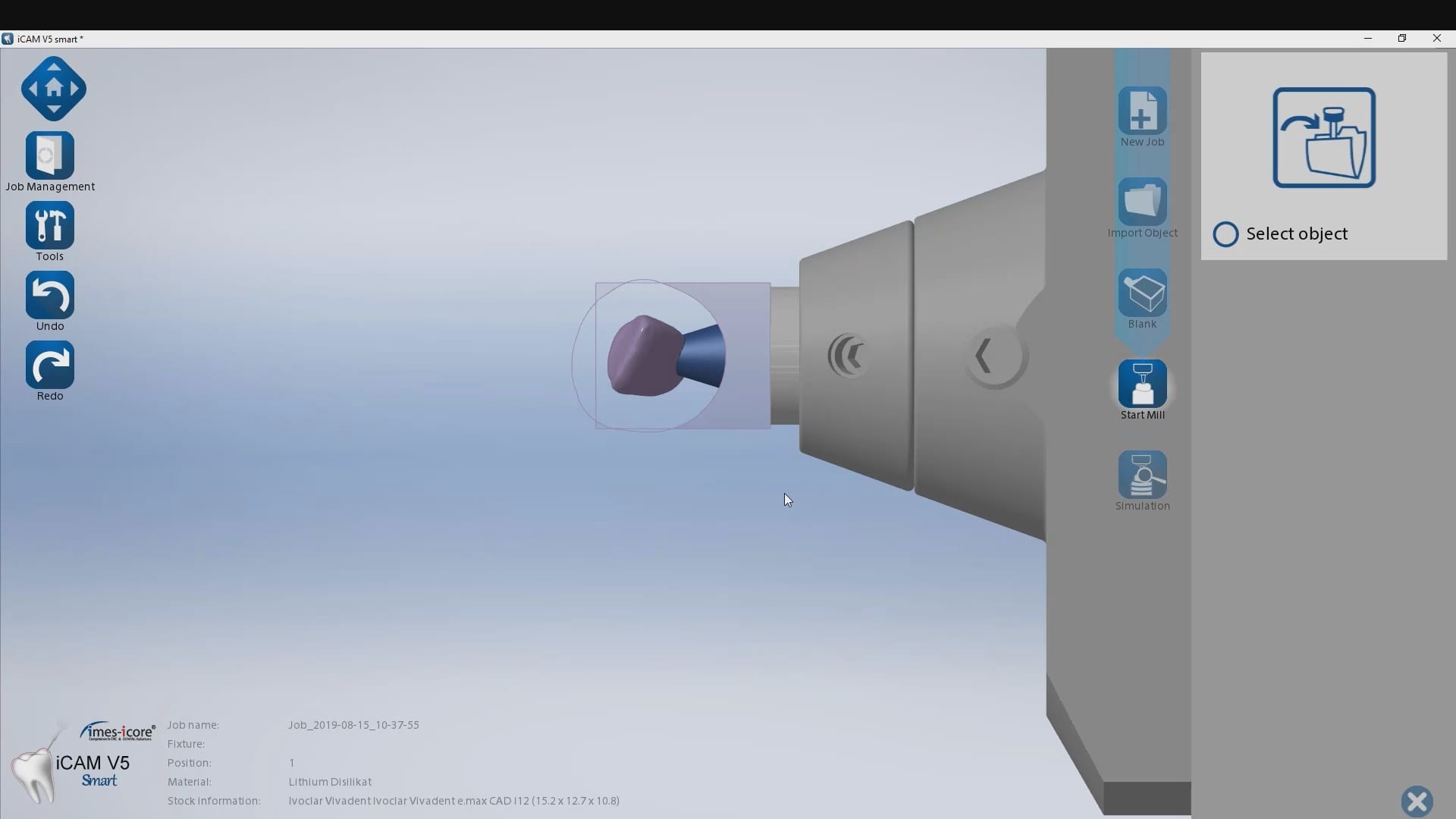

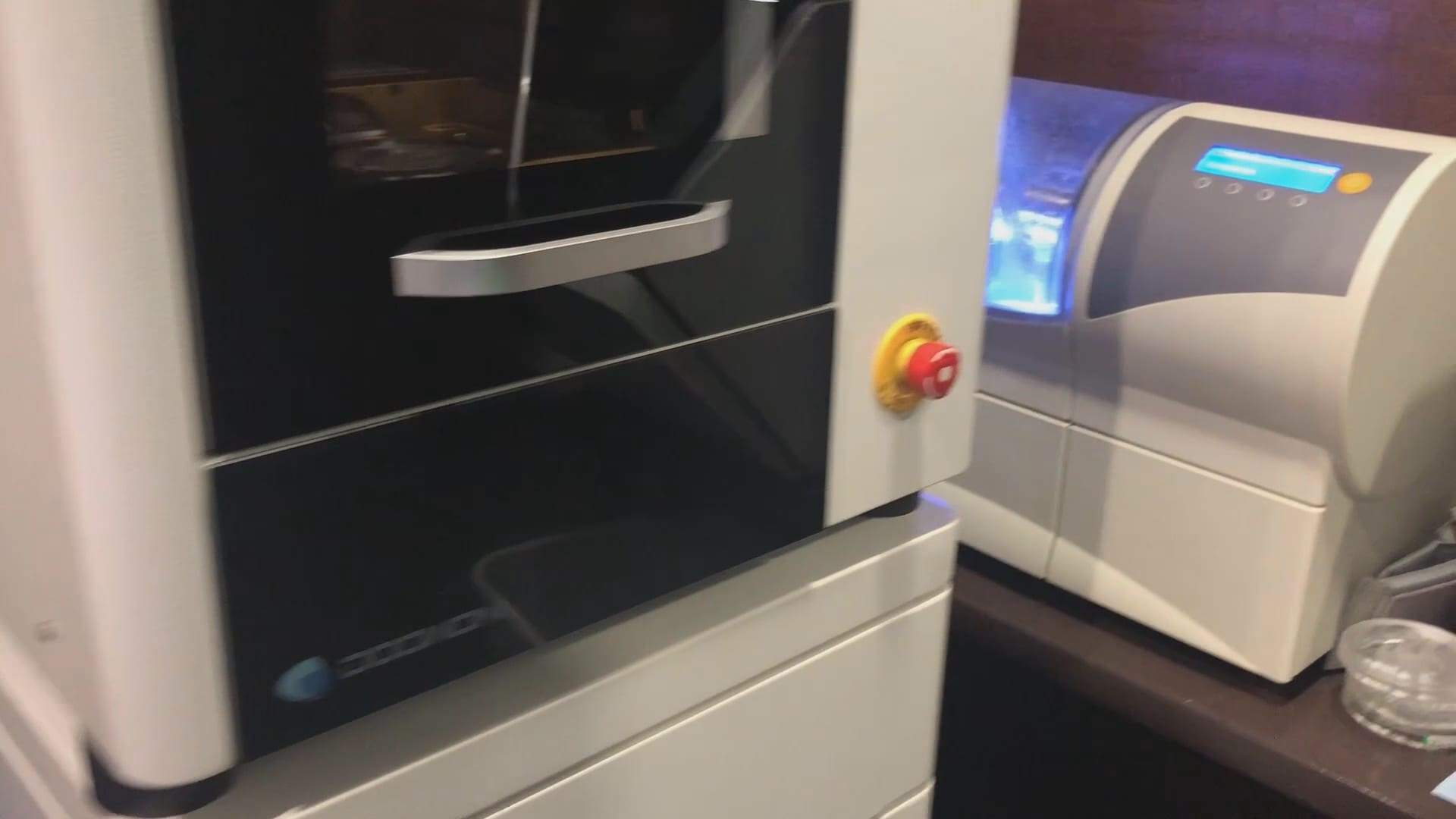

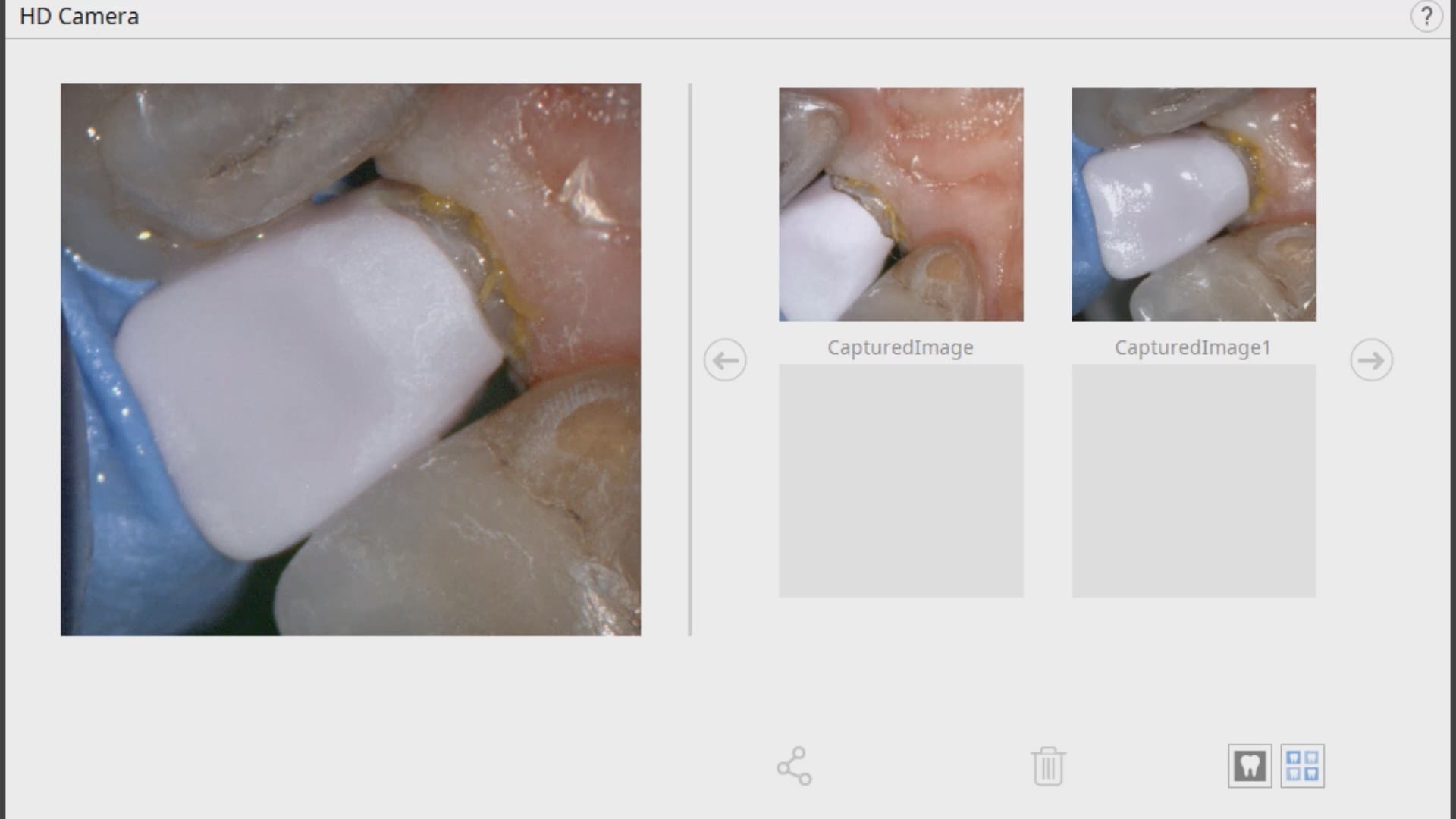

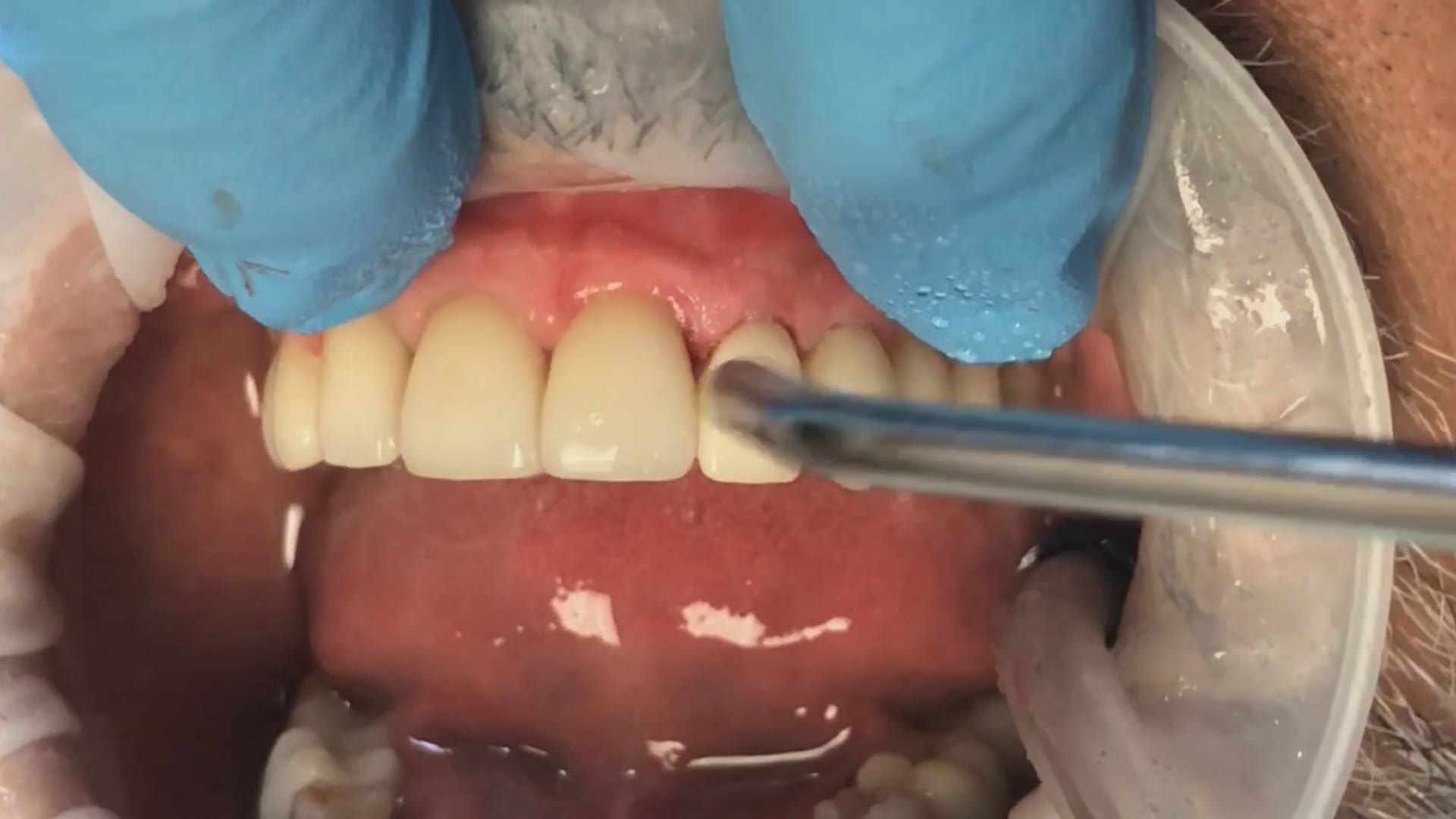

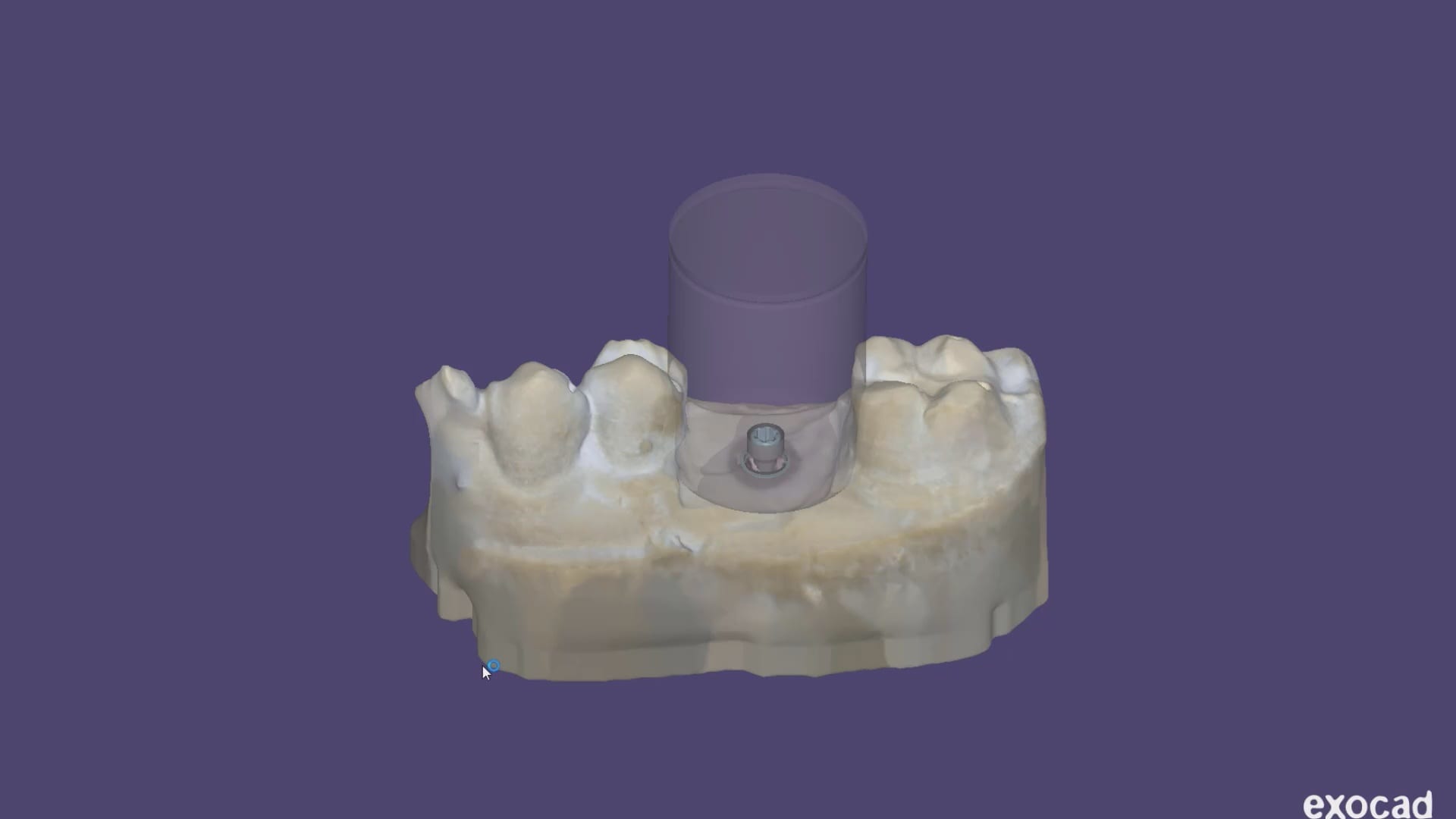

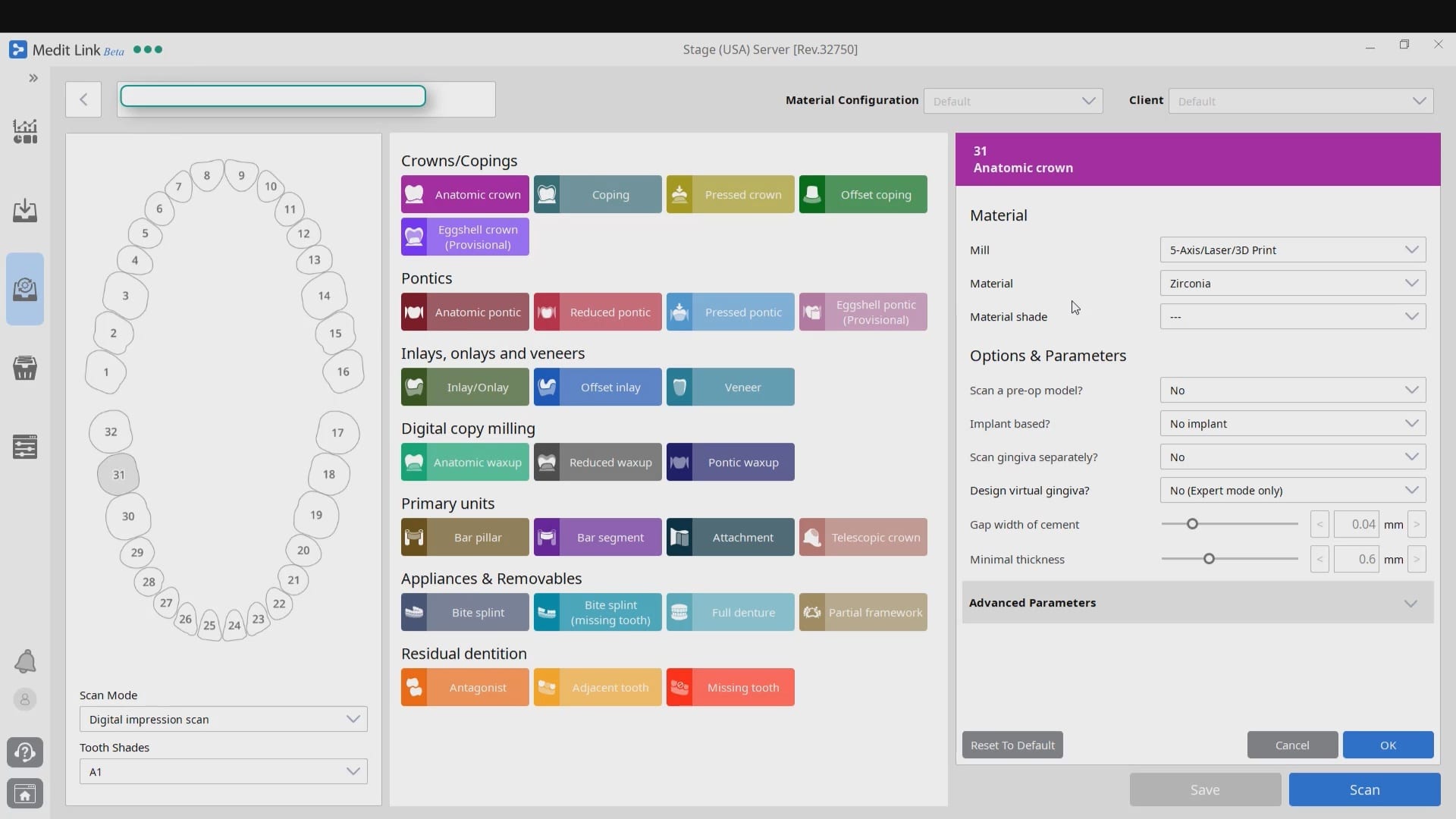

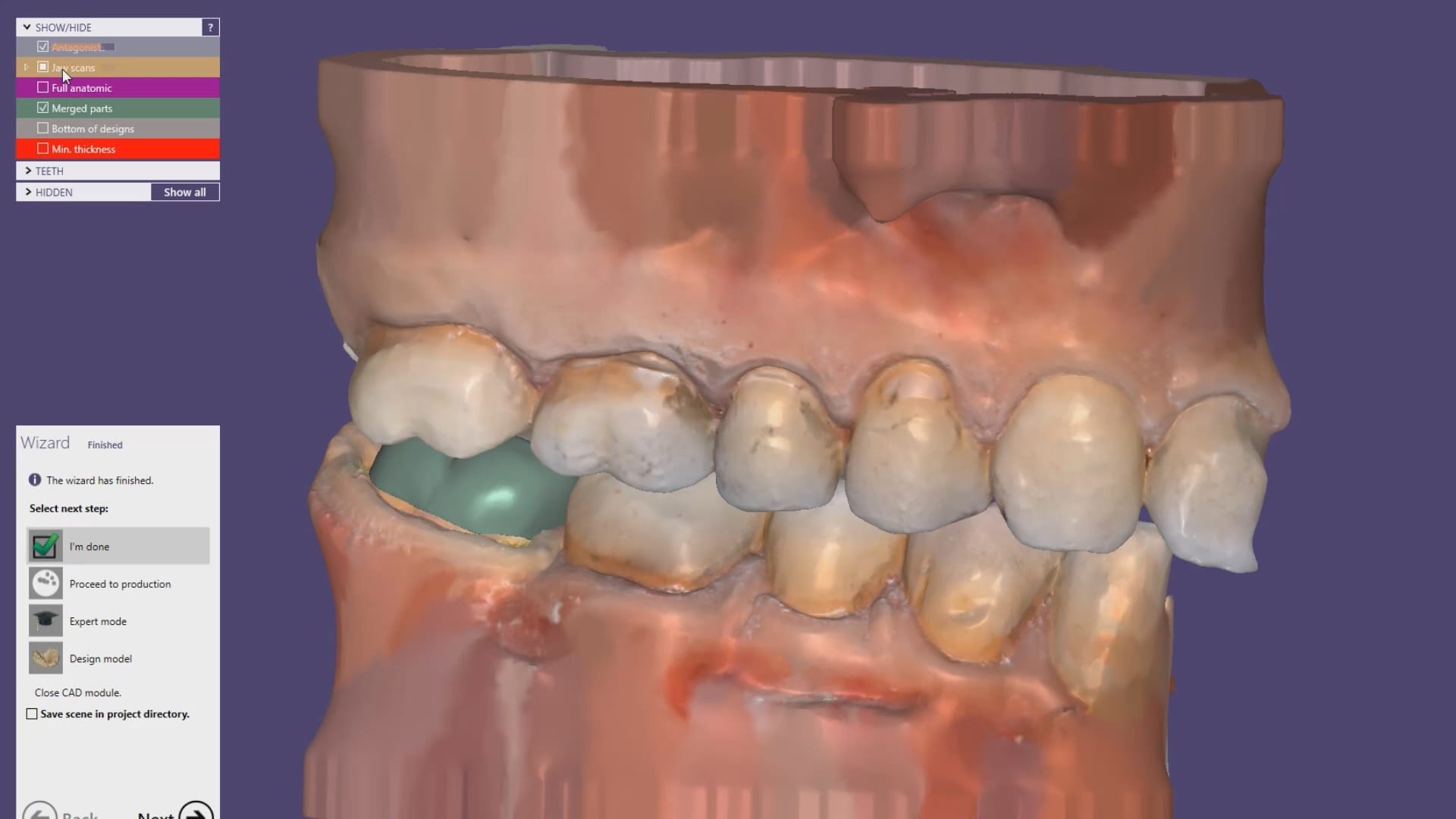

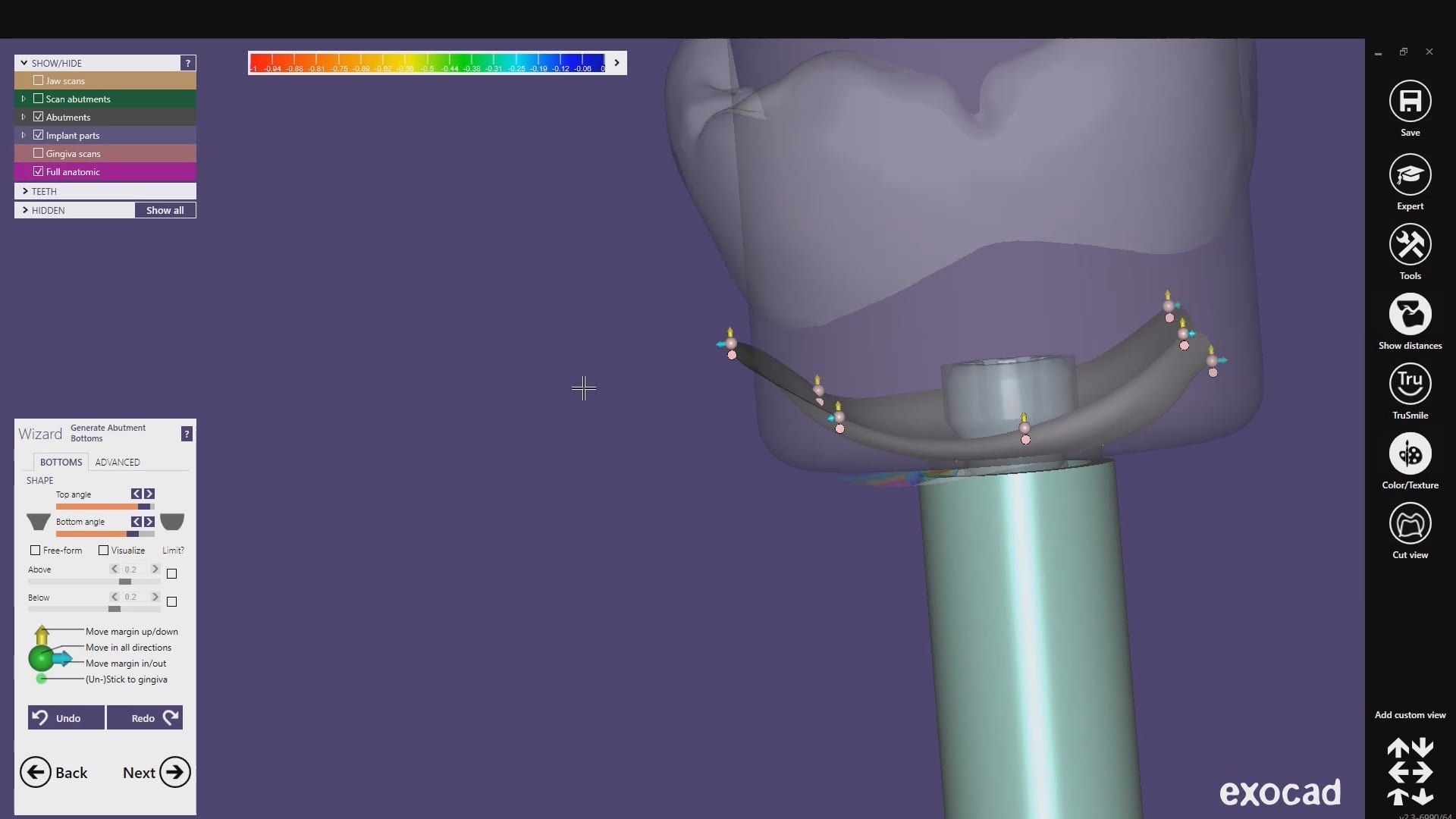

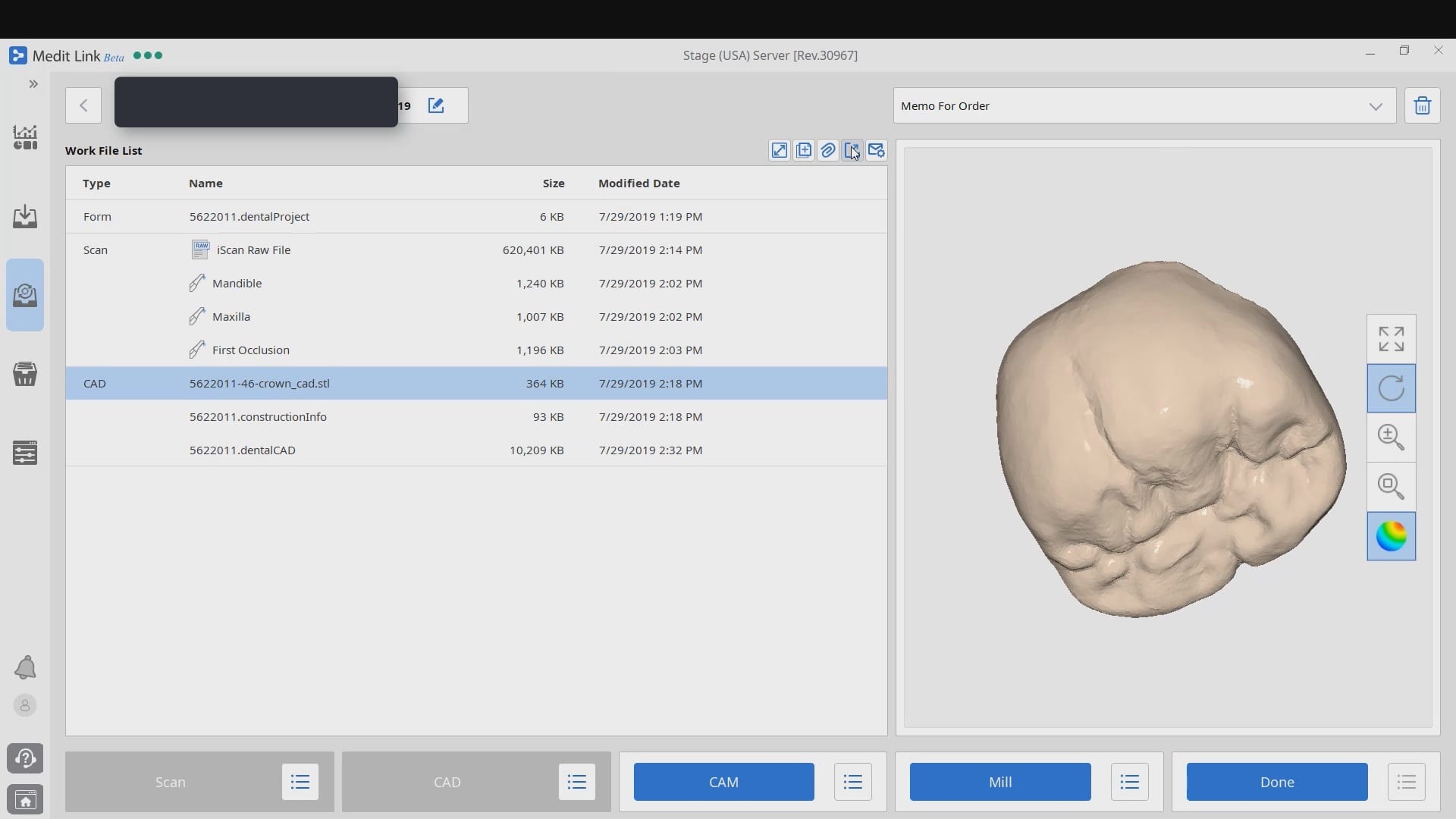

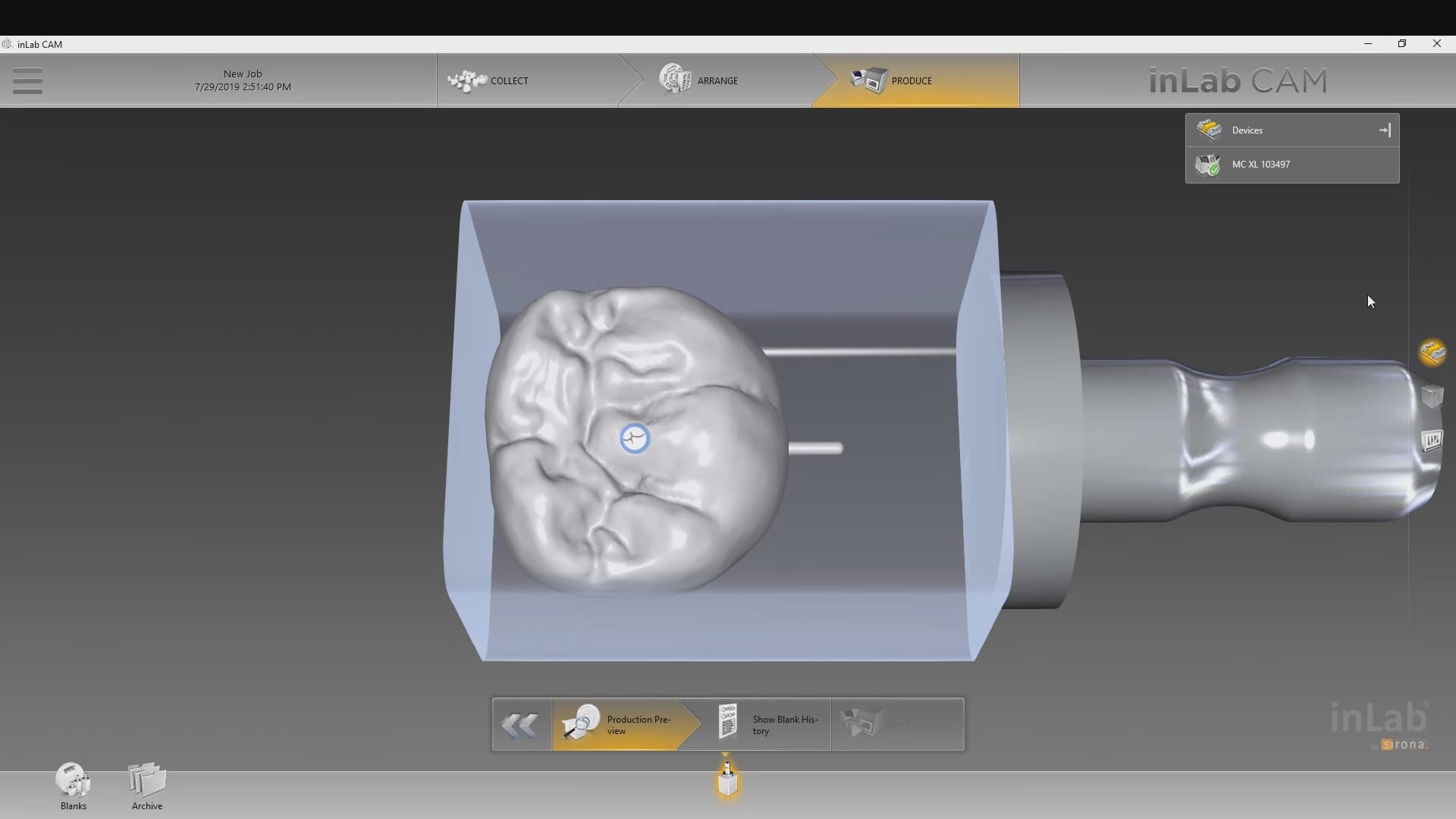

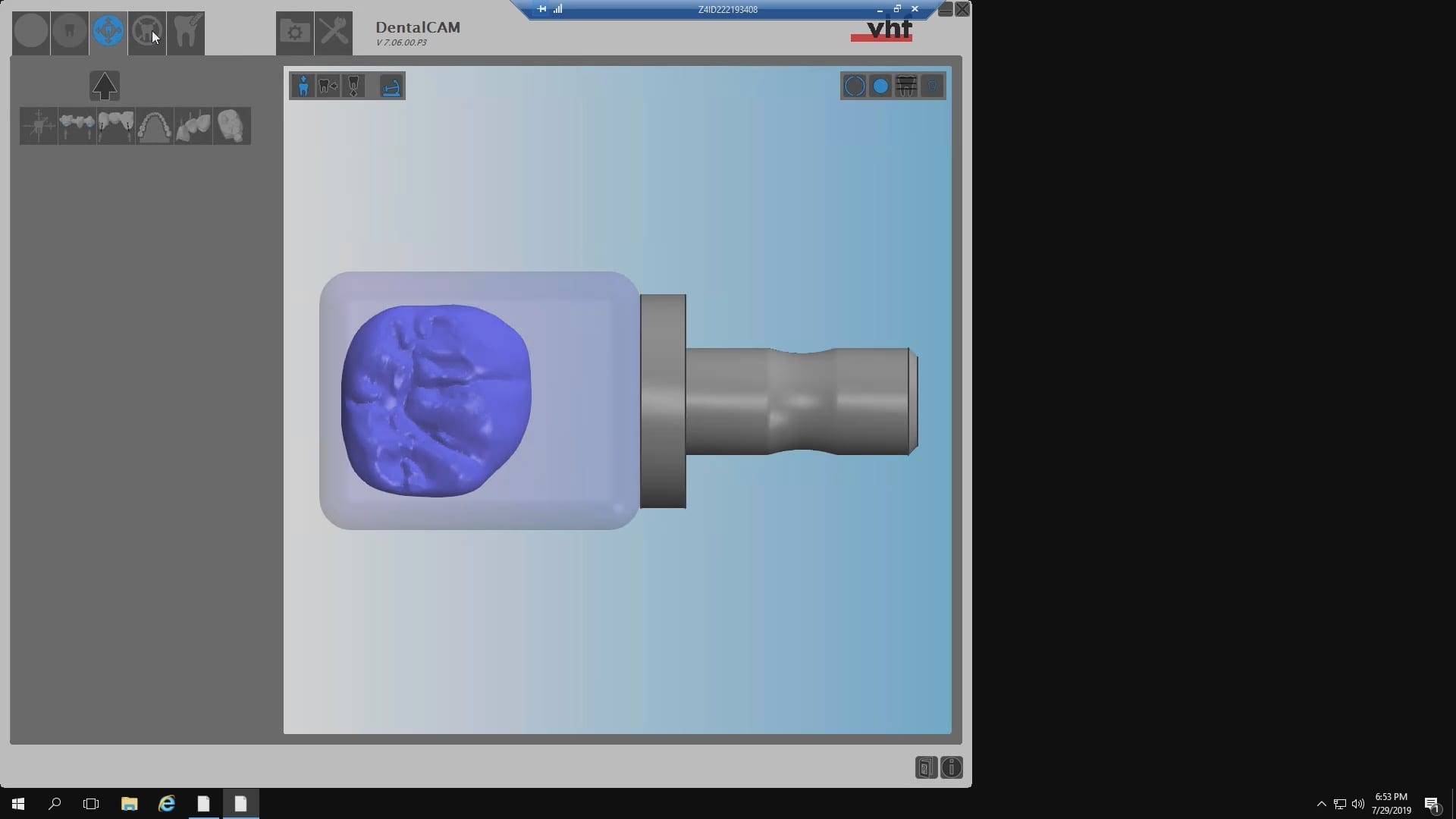

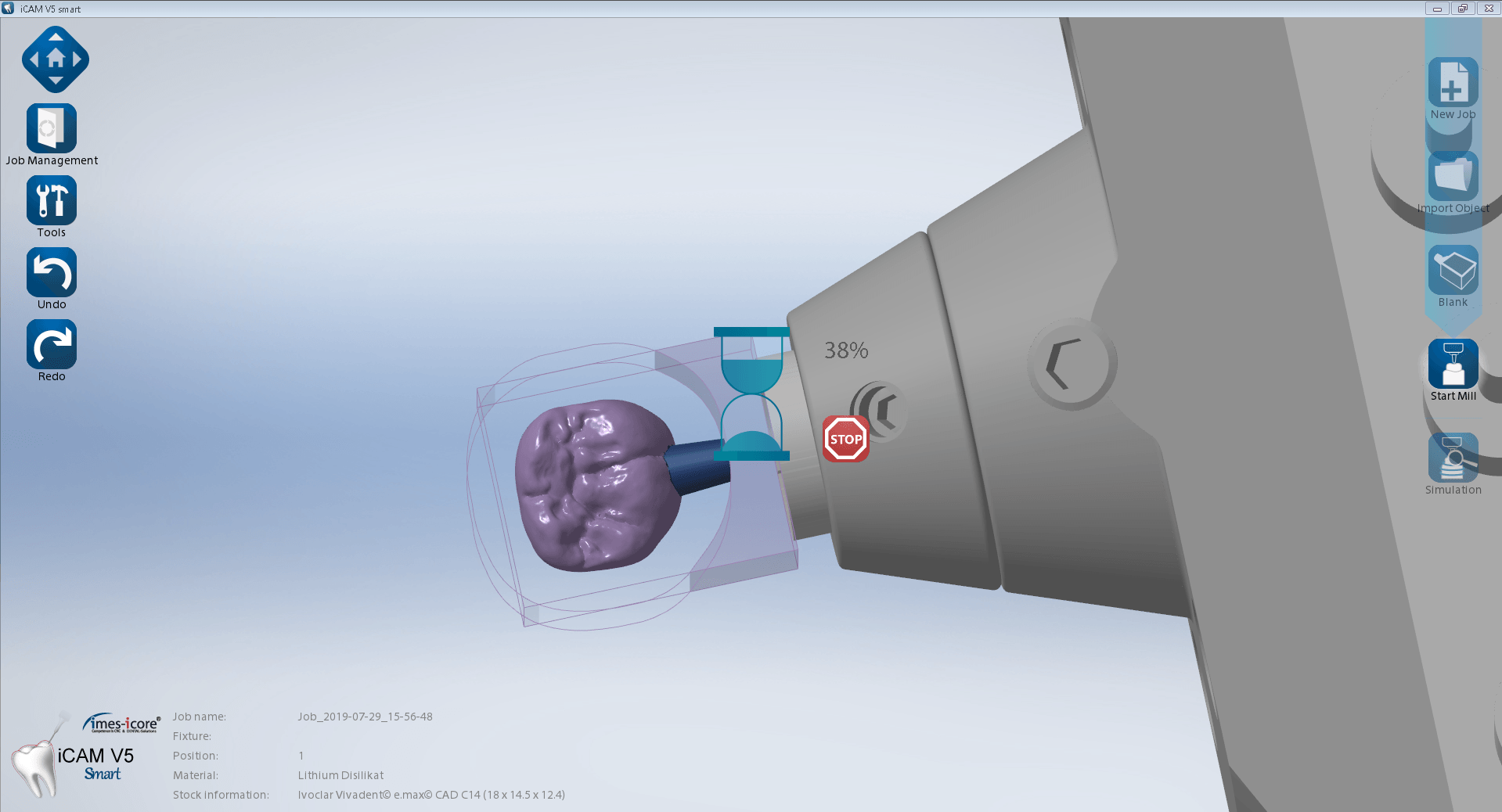

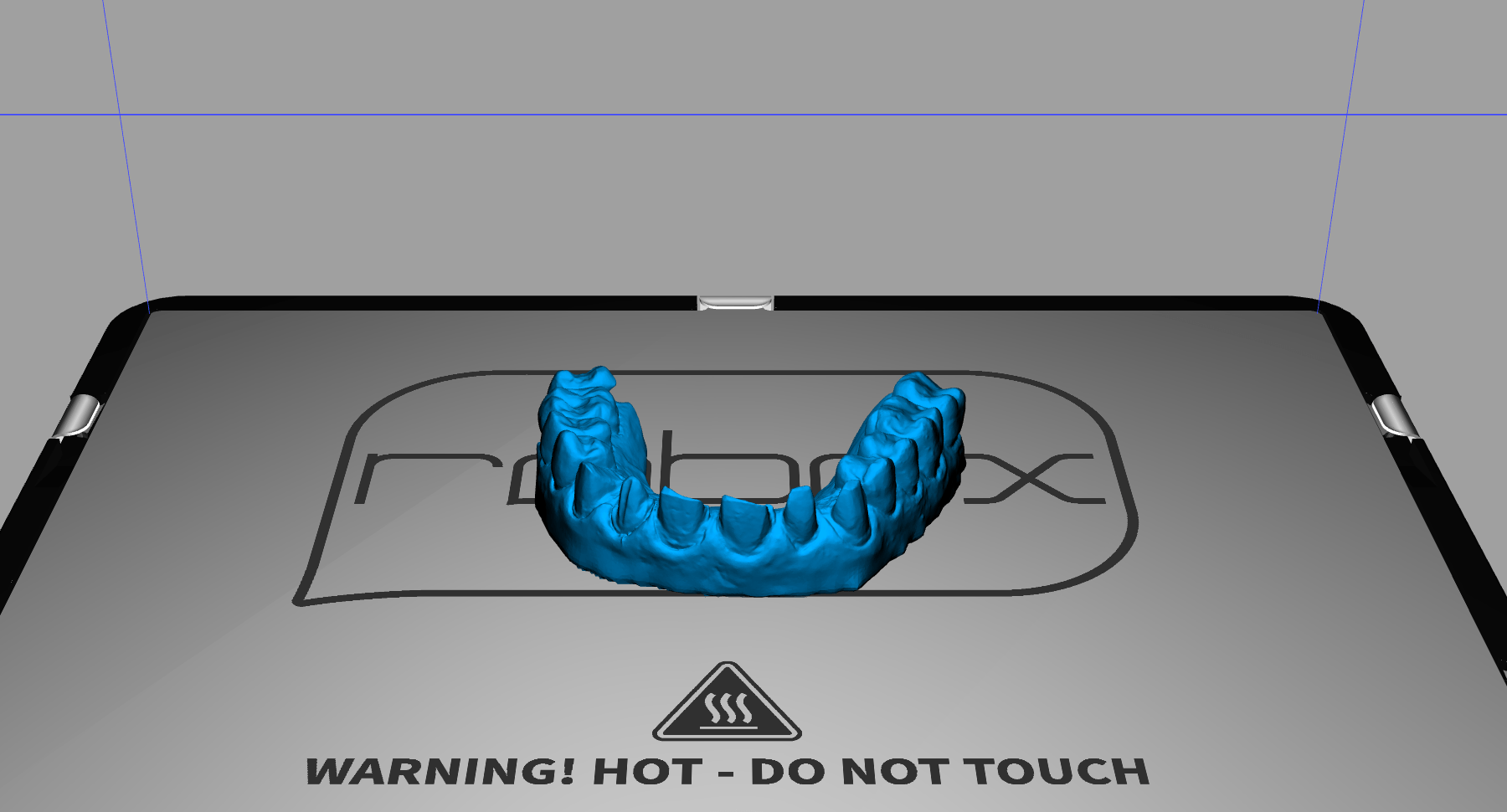

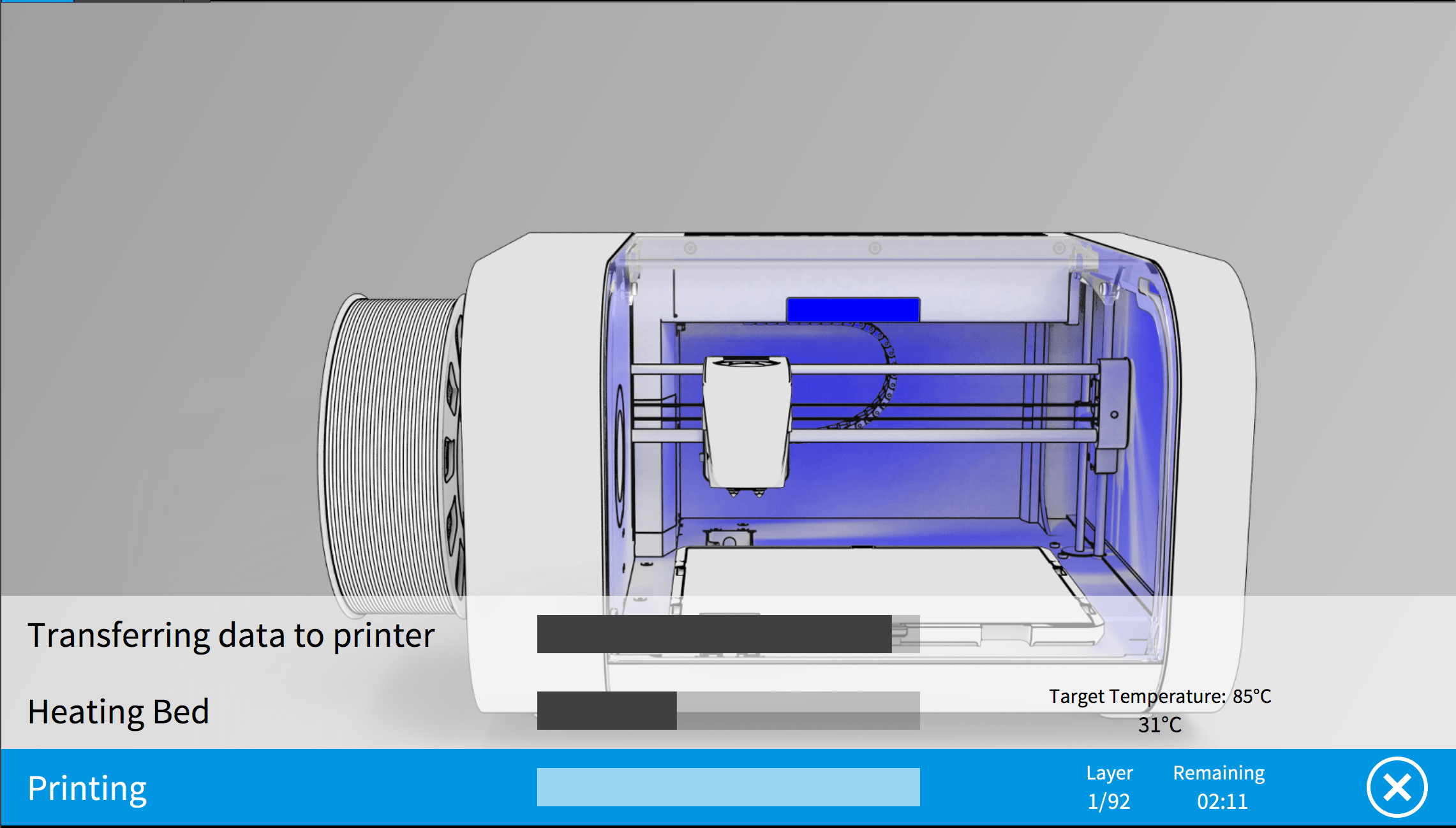

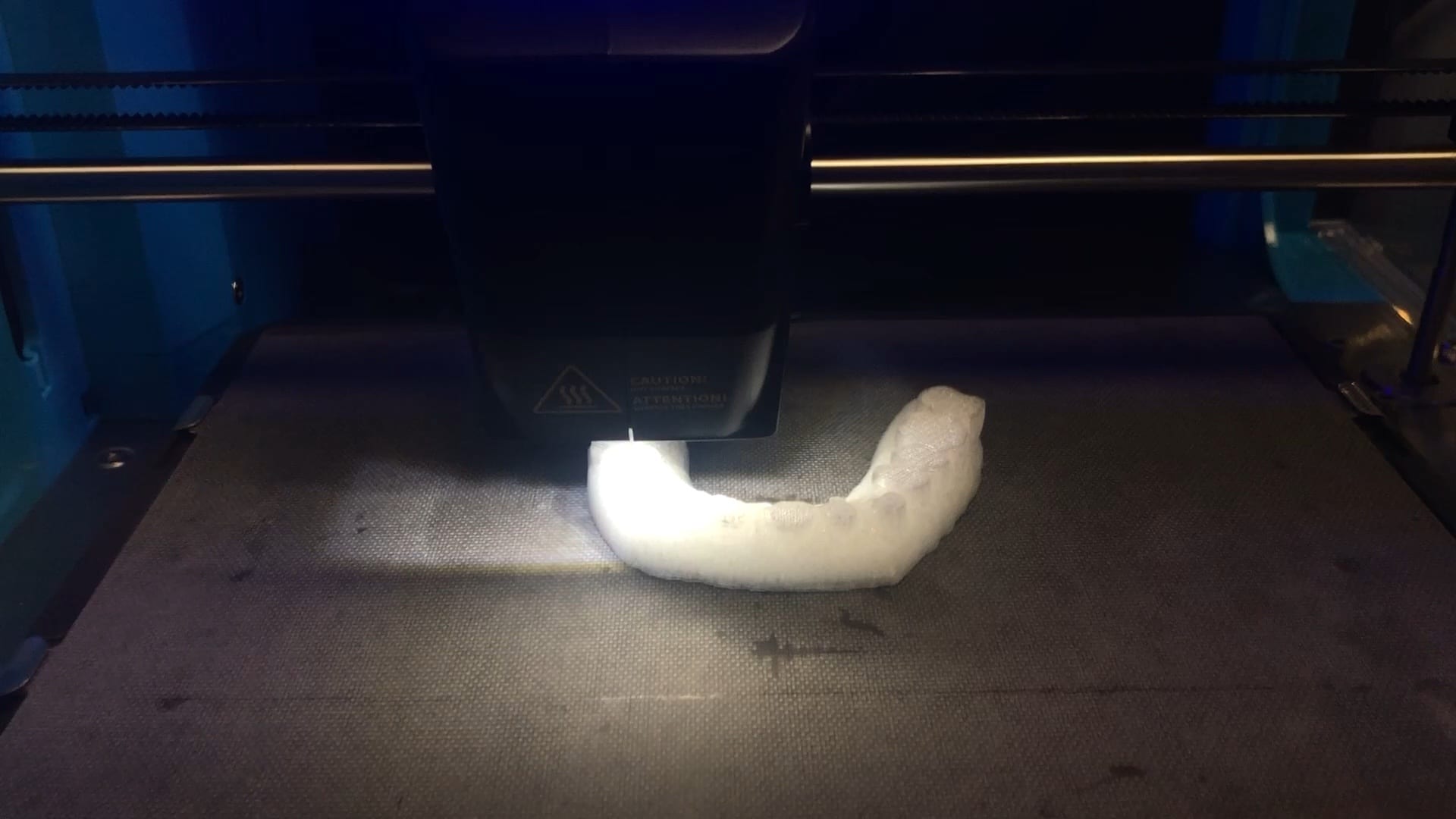

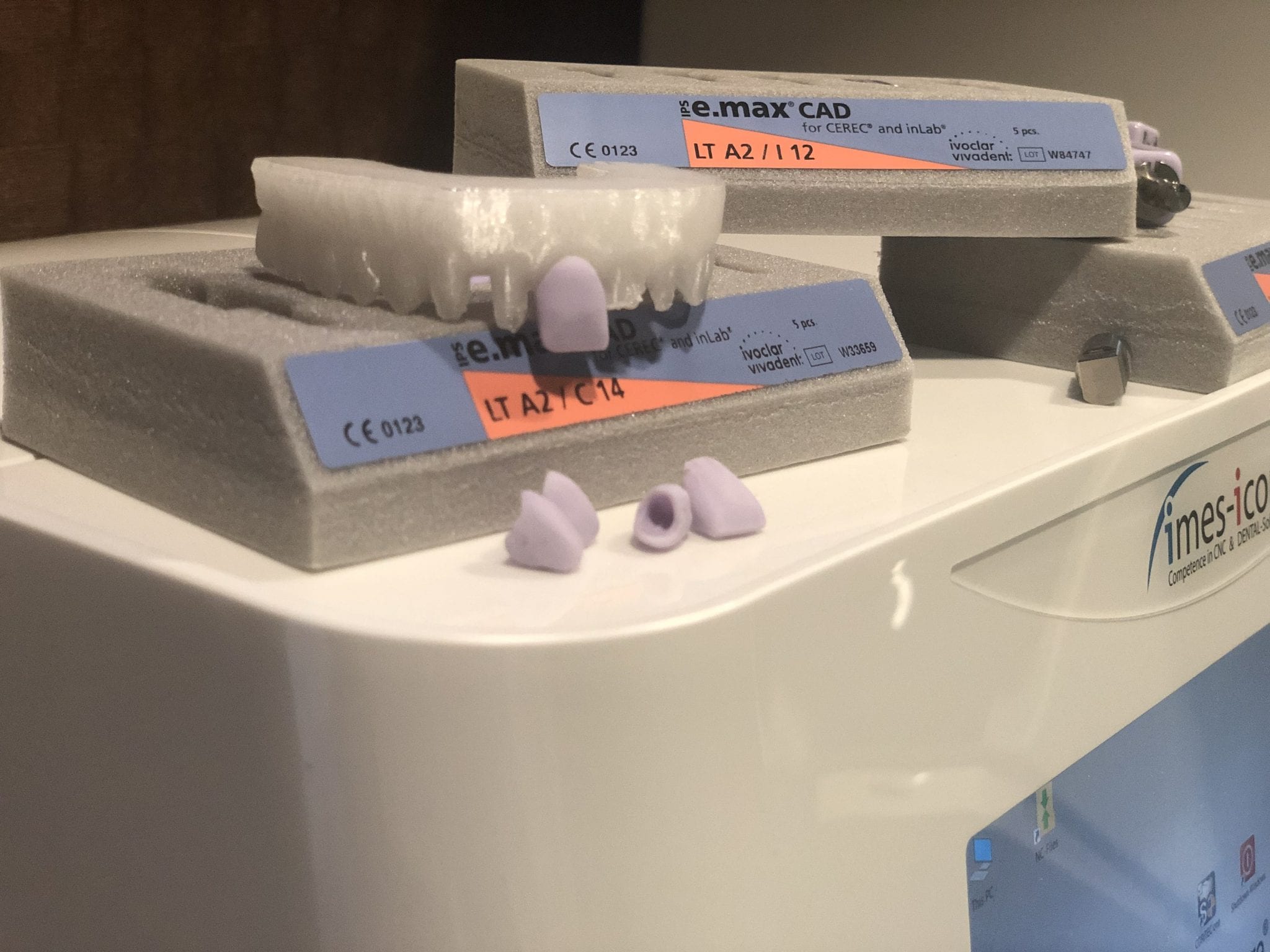

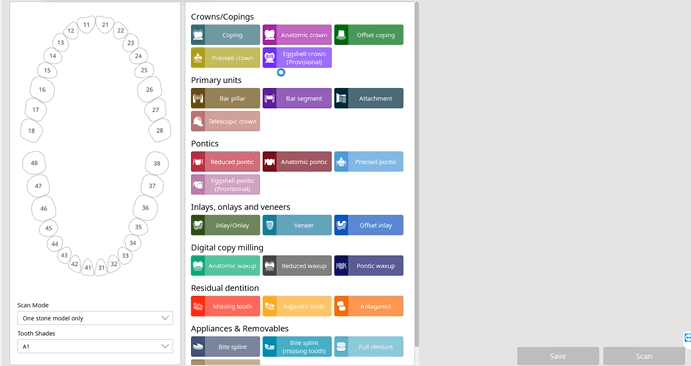

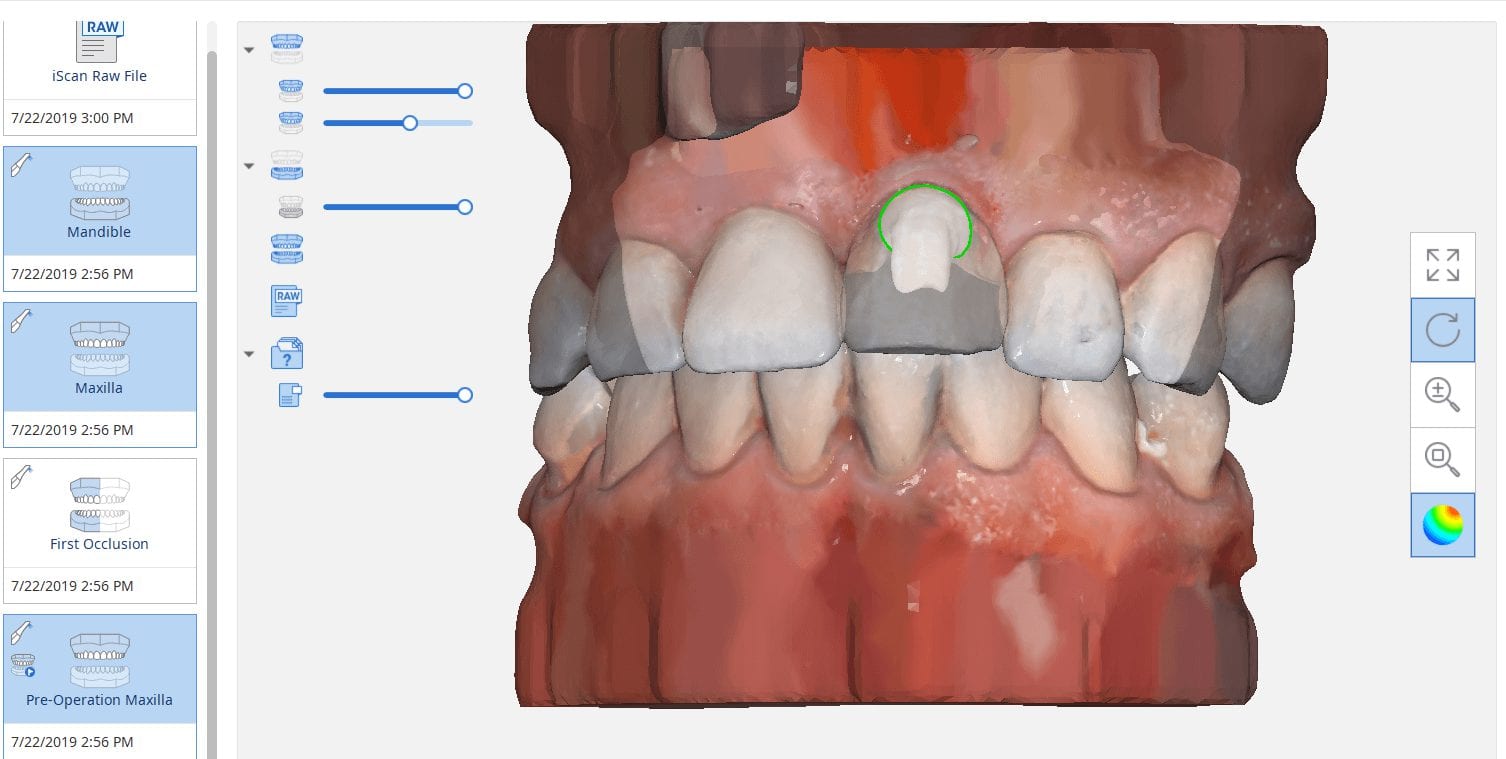

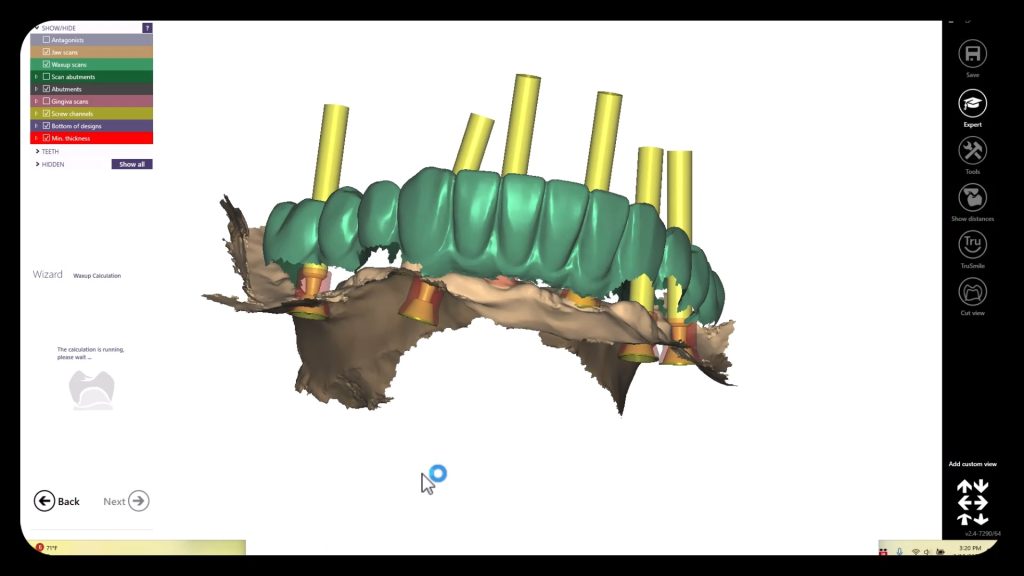

Once the margins are identified and the case is processed it is automatically imported into exocad for design and then sent to the Imes Icore CORiTEC Once for manufacturing. The emax restoration was tried in and then delivered after crystalization.

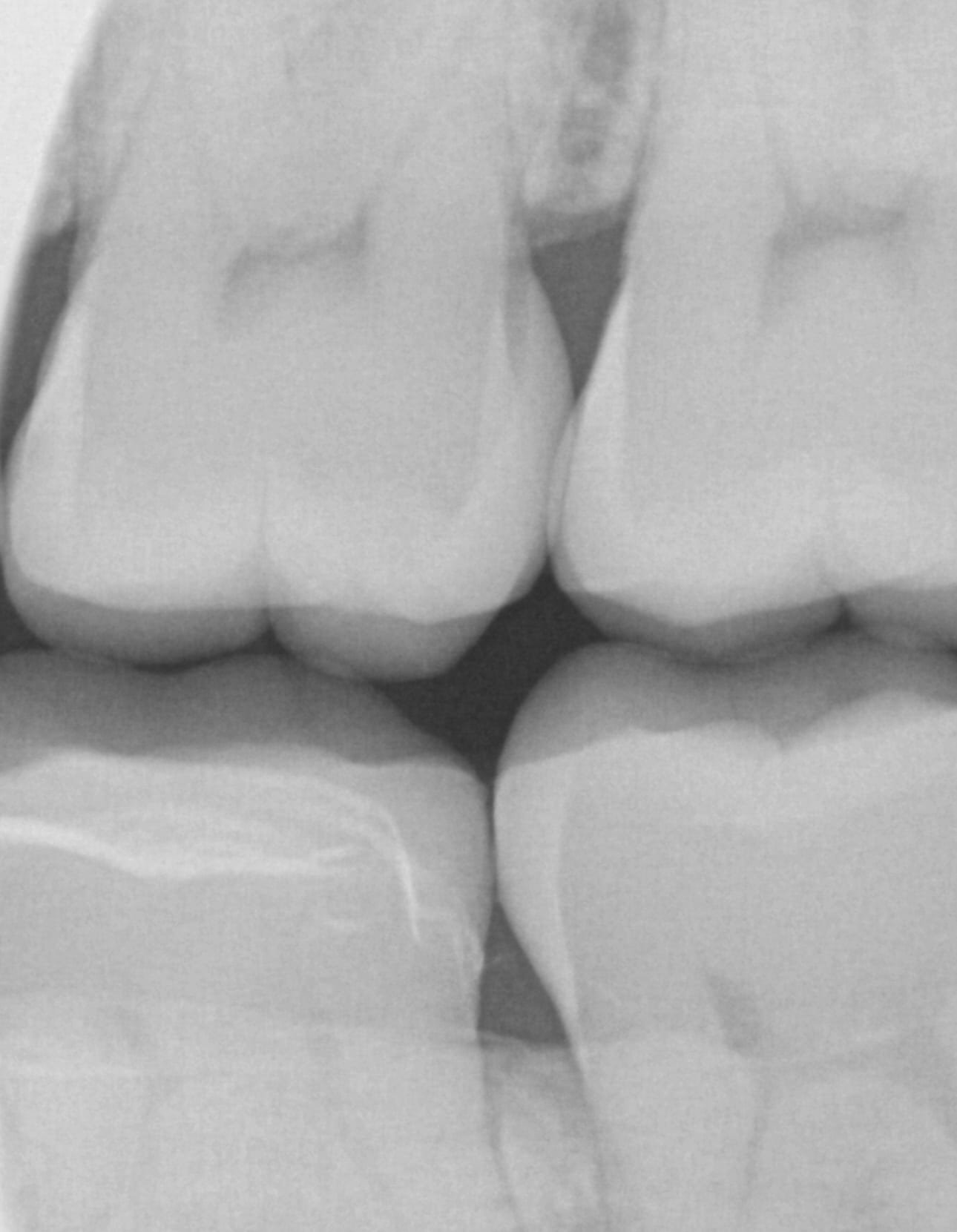

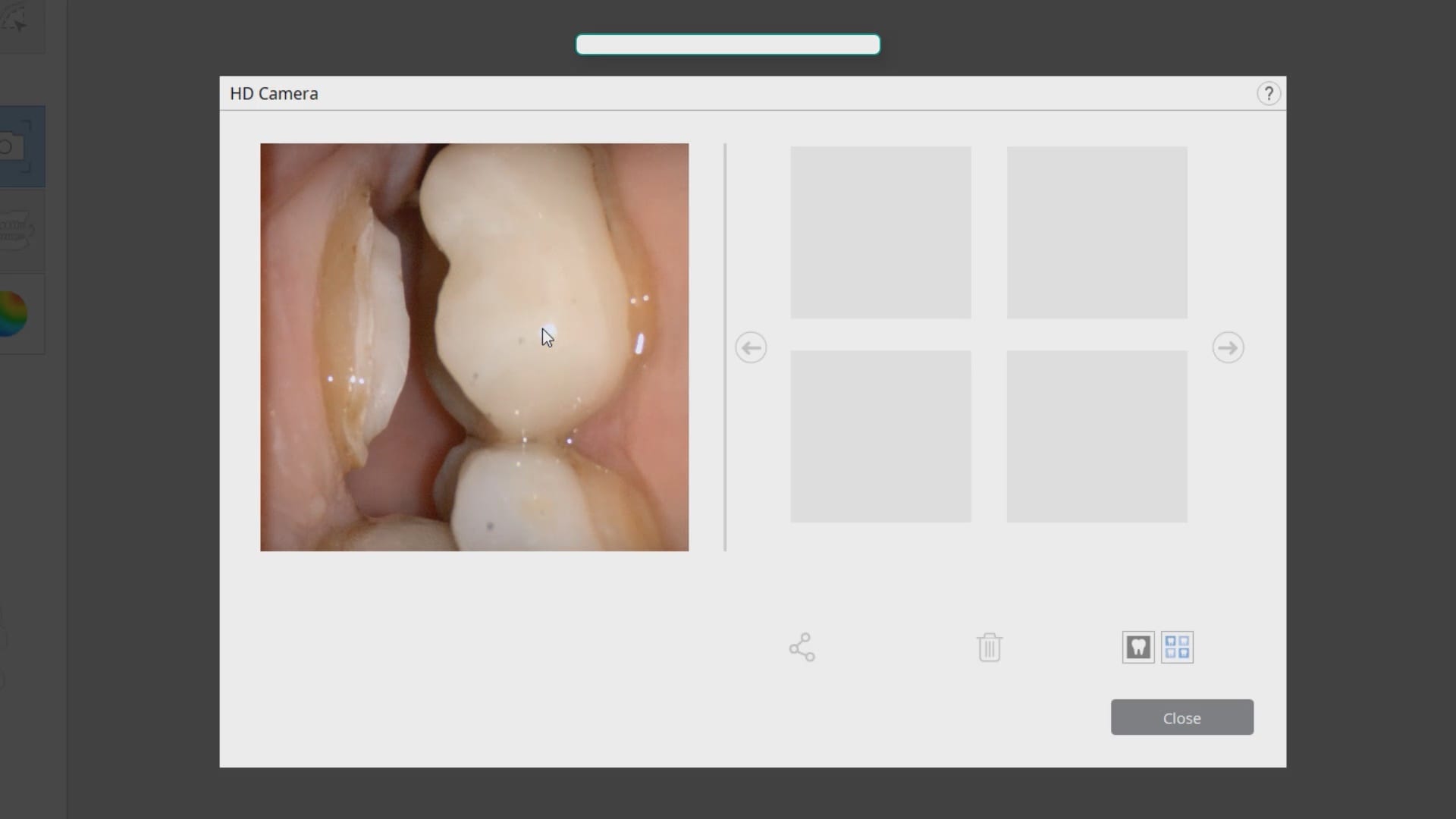

Immediate Post-Op X-Ray taken to verify seat and no excess resin cement

Click Image to Download the OBJ Files And design Along

When we 3D scan the surface of an object, we plot geometric figures (usually triangles) on the surface of that object which is usually round or has some other geometric shape. A satellite beam hitting the surface of the earth is a good way to visualize the scanning process as the photo illustrates.

When we 3D scan the surface of an object, we plot geometric figures (usually triangles) on the surface of that object which is usually round or has some other geometric shape. A satellite beam hitting the surface of the earth is a good way to visualize the scanning process as the photo illustrates.

You must be logged in to post a comment.