We are very pleased with millbox and the imes icore coritec one for a chairside milling solution. We’ve been testing it for a long time and its CAM (millbox) is very intuitive and the results are always predictable. It can mill titanium abutments, emax, and zirconia blocks.

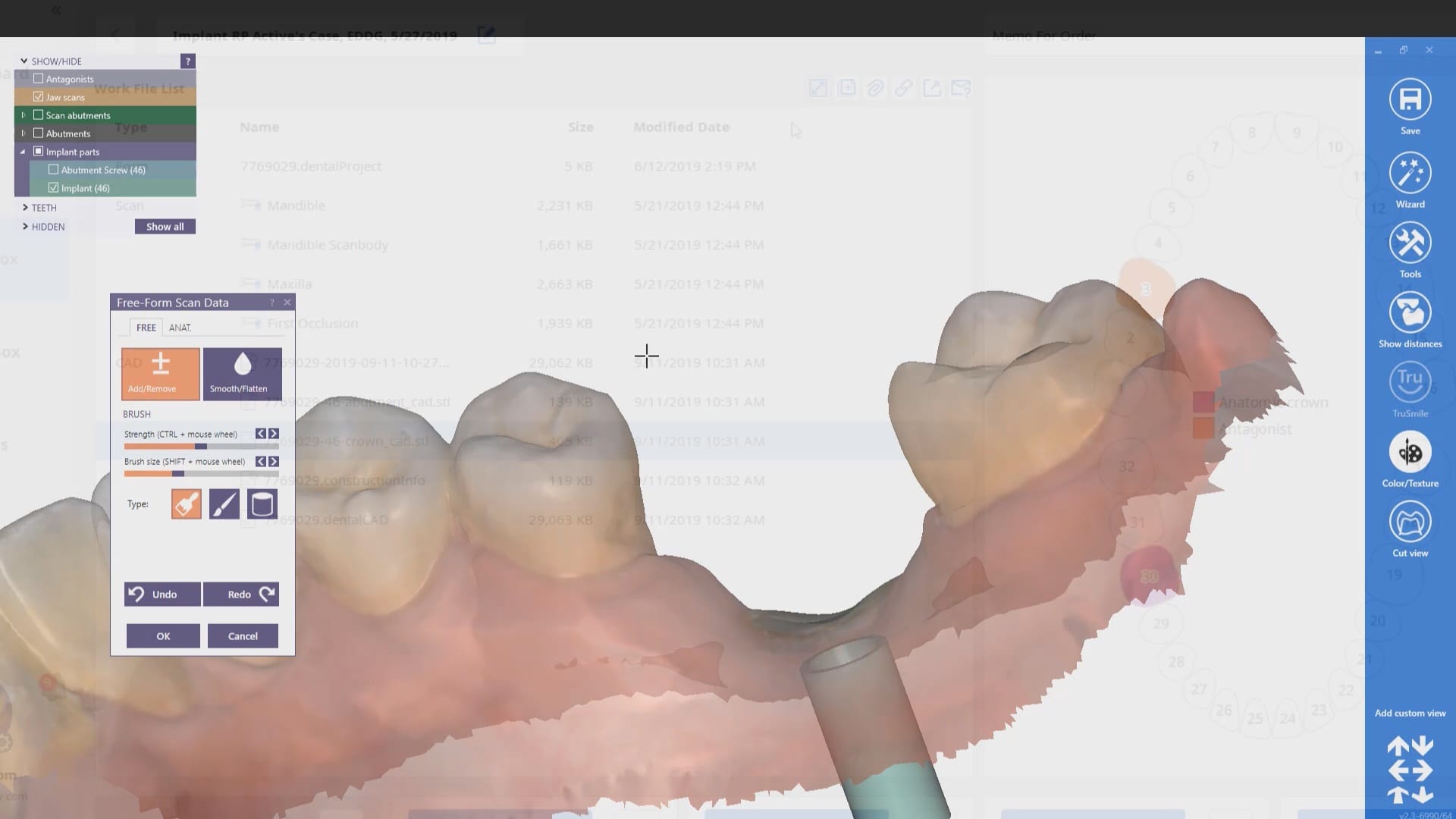

The following videos illustrate how you can image a scanbody intra-orally and then design it in cad software. Here we used exocad to identify the biomax RP implant and designed both the custom titanium abutment and the suprastructure, both of which were milled with the CORiTEC ONE

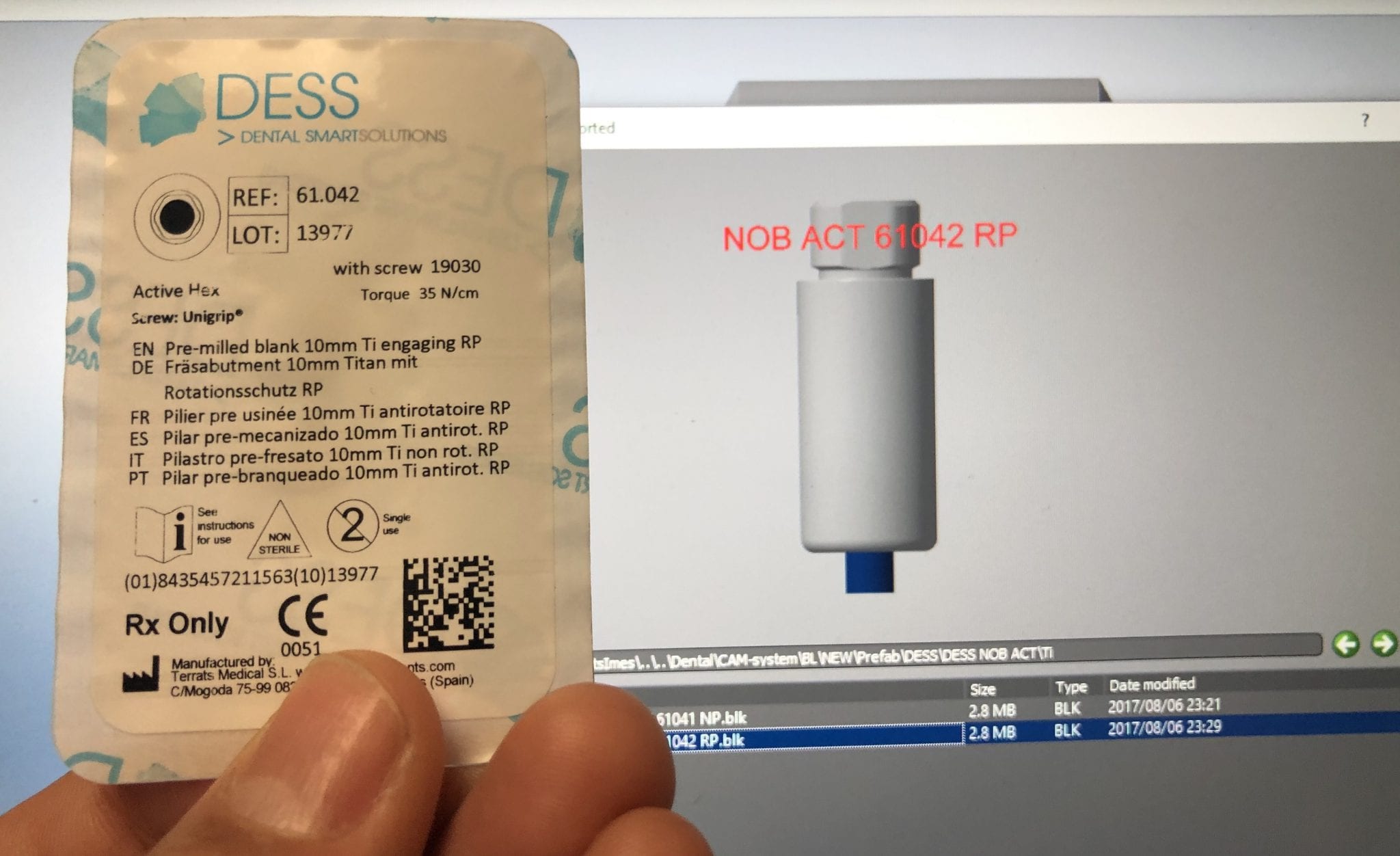

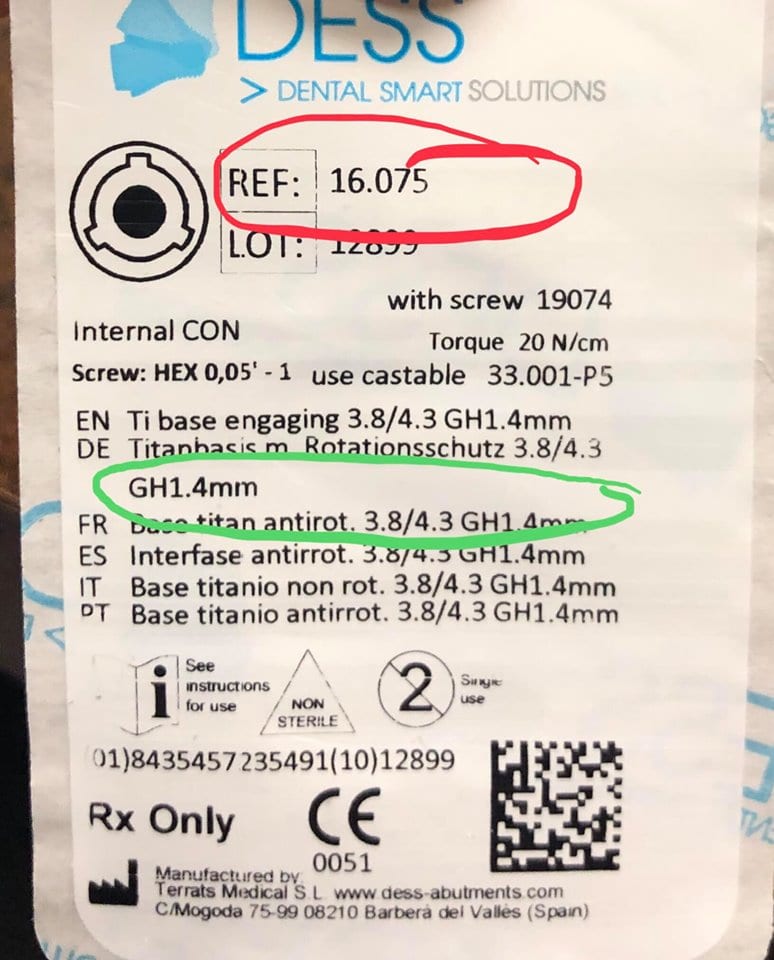

There are so many implant and component libraries in cad/cam dentistry which can lead to a lot of confusion. What we highly recommend is that you visually compare the part numbers that you will be using with the part numbers displayed on the millbox software. One letter or number difference and the mistakes will have a profound impact on the bottom line of a dental practice

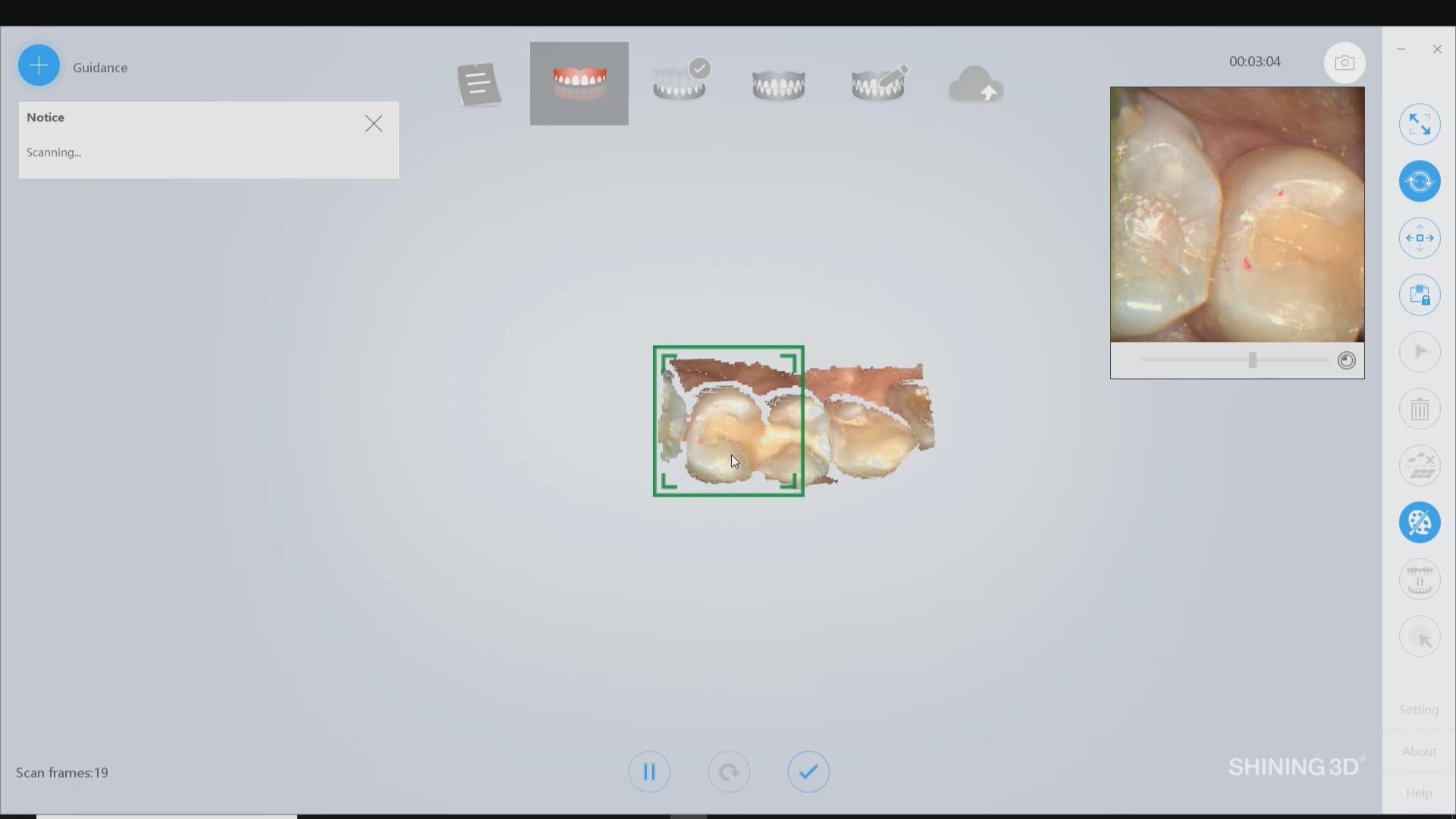

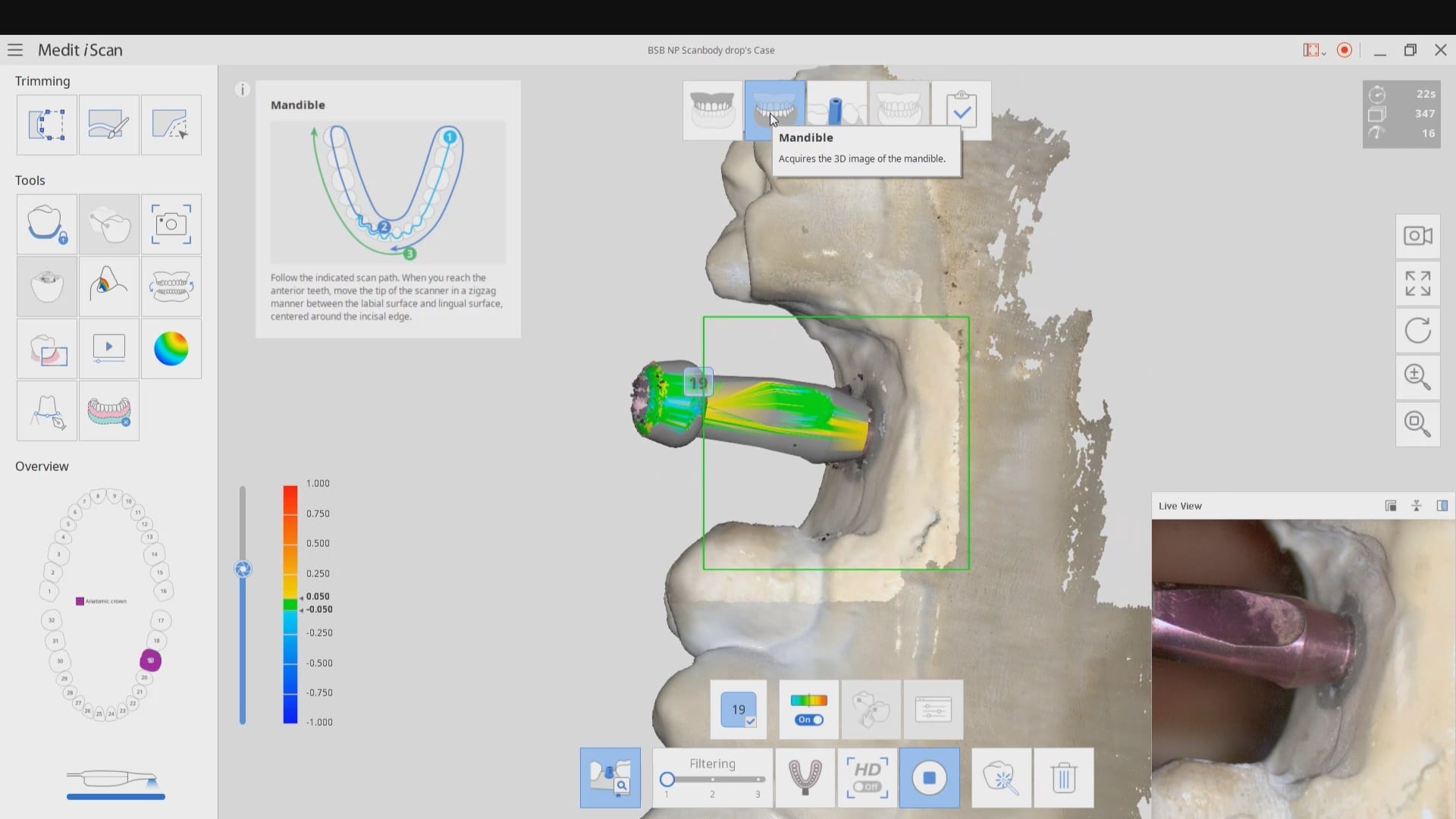

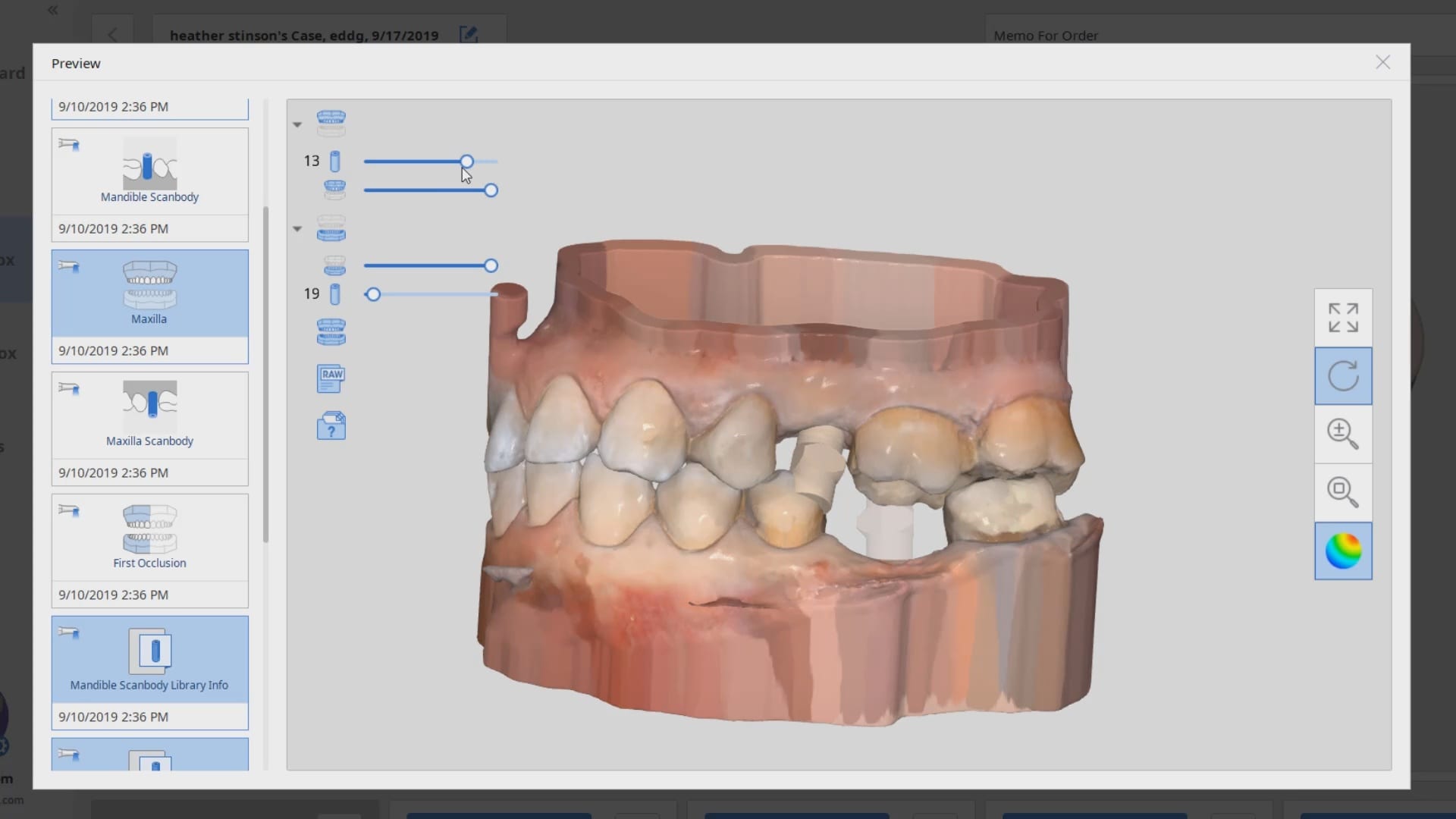

Medit has launched a software that is the greatest advancements in digital dentistry in more than a decade! With artificial intelligence, you can identify the scanbody during intra-oral digital scans. This has many implications for accurate scan captures and skipping multiple steps in the design process in CAD software like exocad.

But there is more! This will knock your socks off. You can build your own custom library for scanbodies or you can use geometries of abutment libraries from your favorite implant line. In this article we show how to import the stl file for a physical impression abutment (Closed Tray- Blueskybio Part #MIJH) and use it as a scanbody. Just watch the following videos

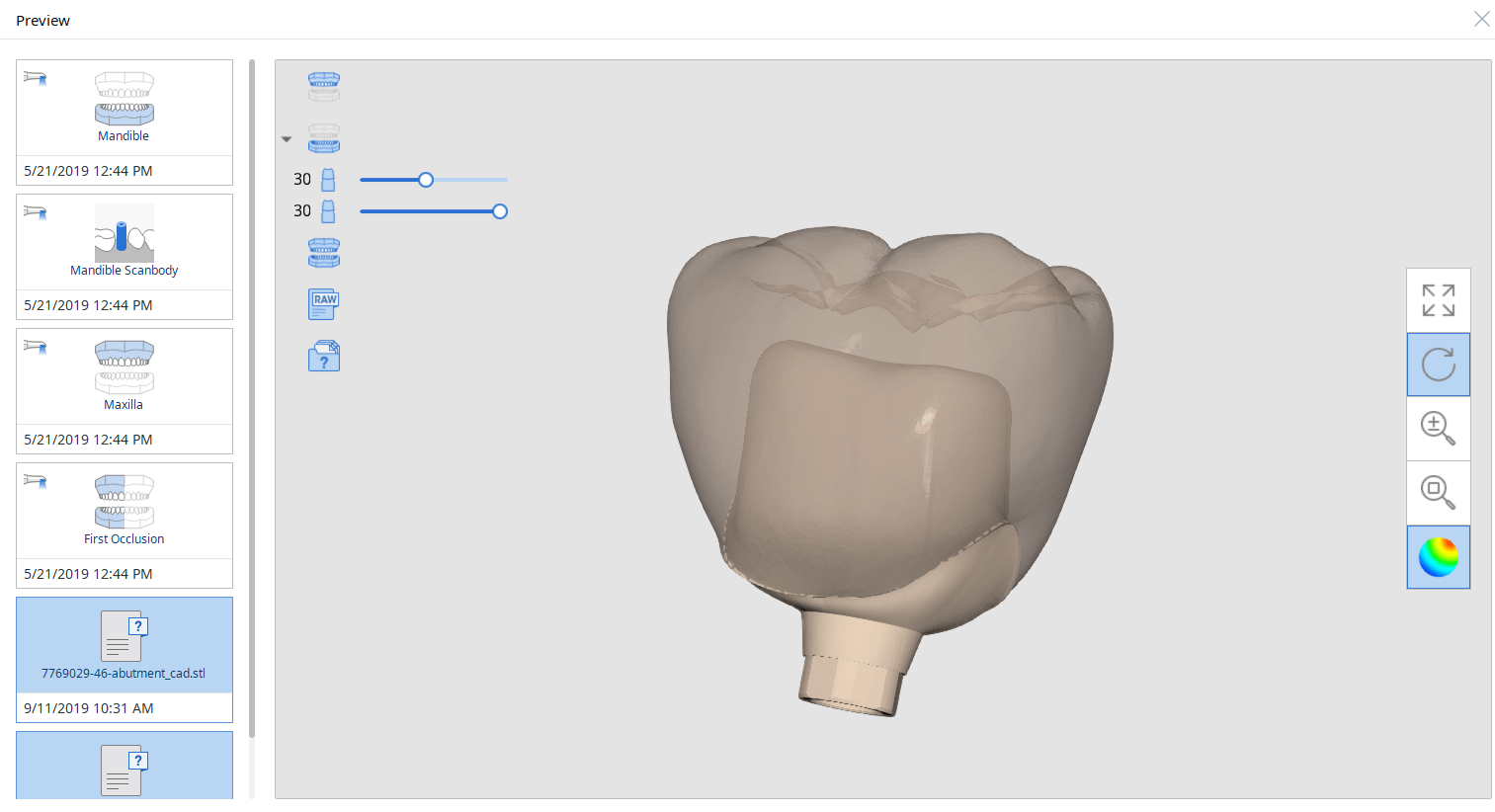

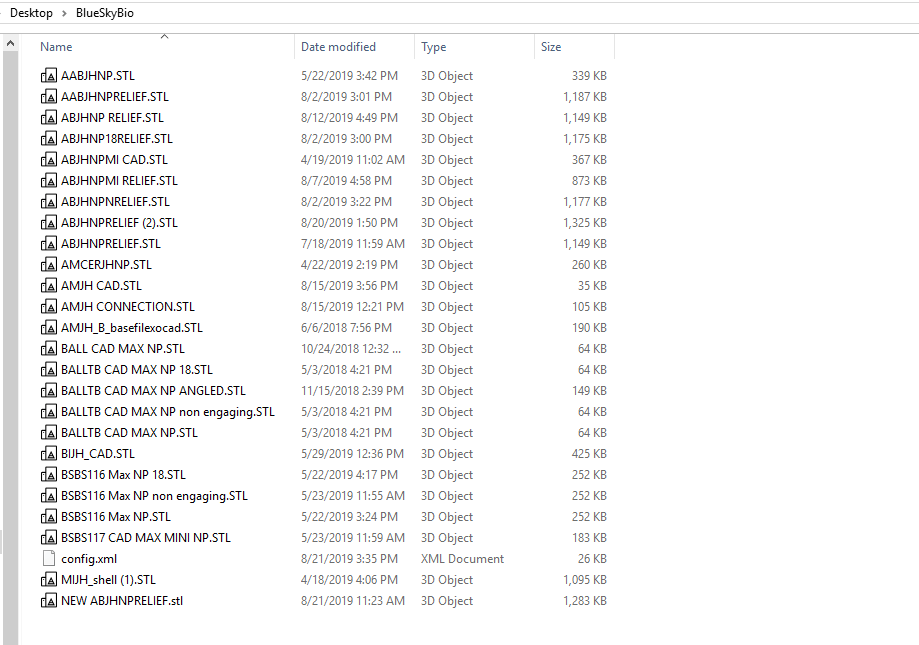

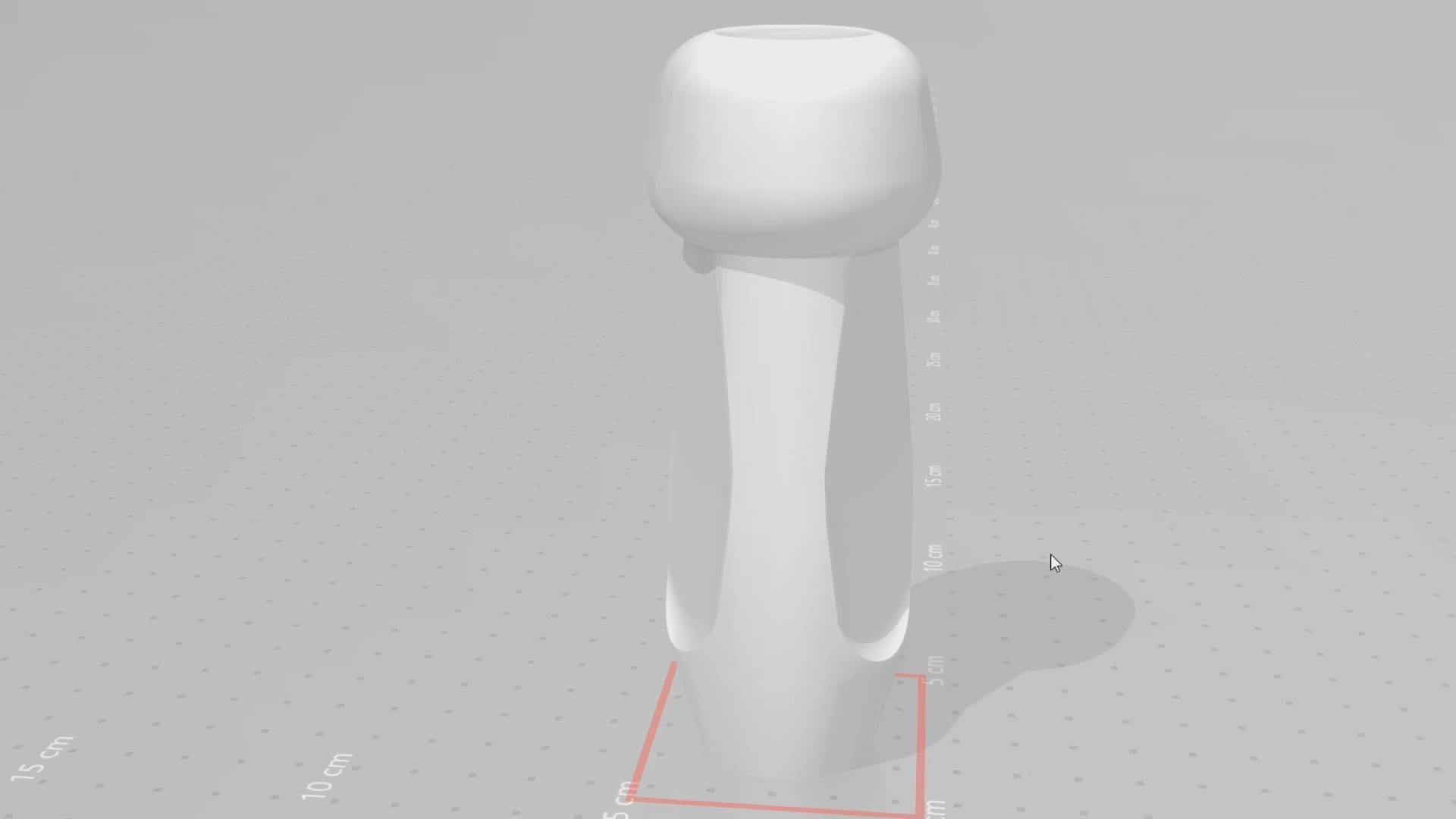

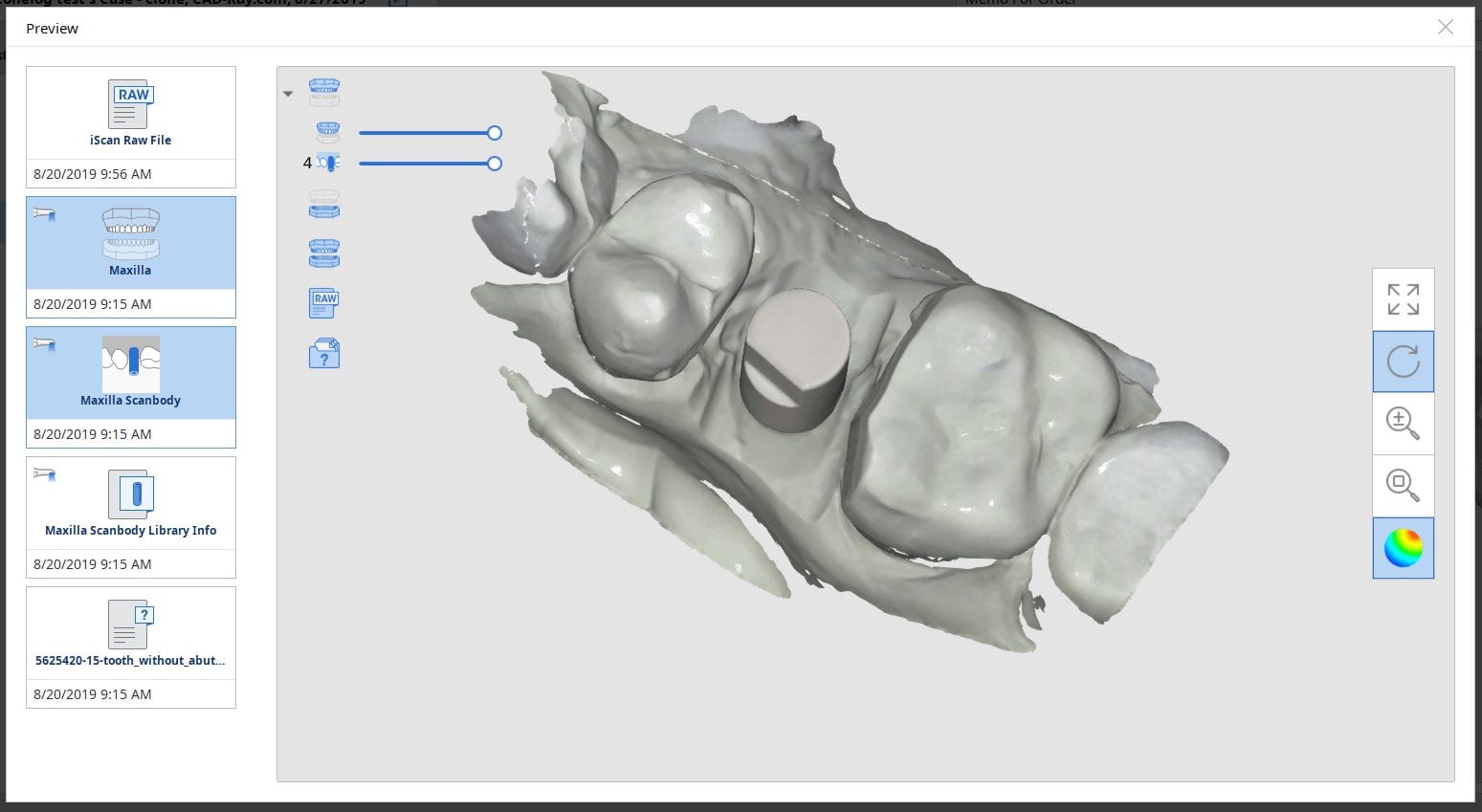

A lot of implant manufacturers will readily distribute their libraries of abutments and scanbodies. Here, we just chose the MIJH impression abutment and previewed it in one of the many free 3D viewer programs included in windows 10.

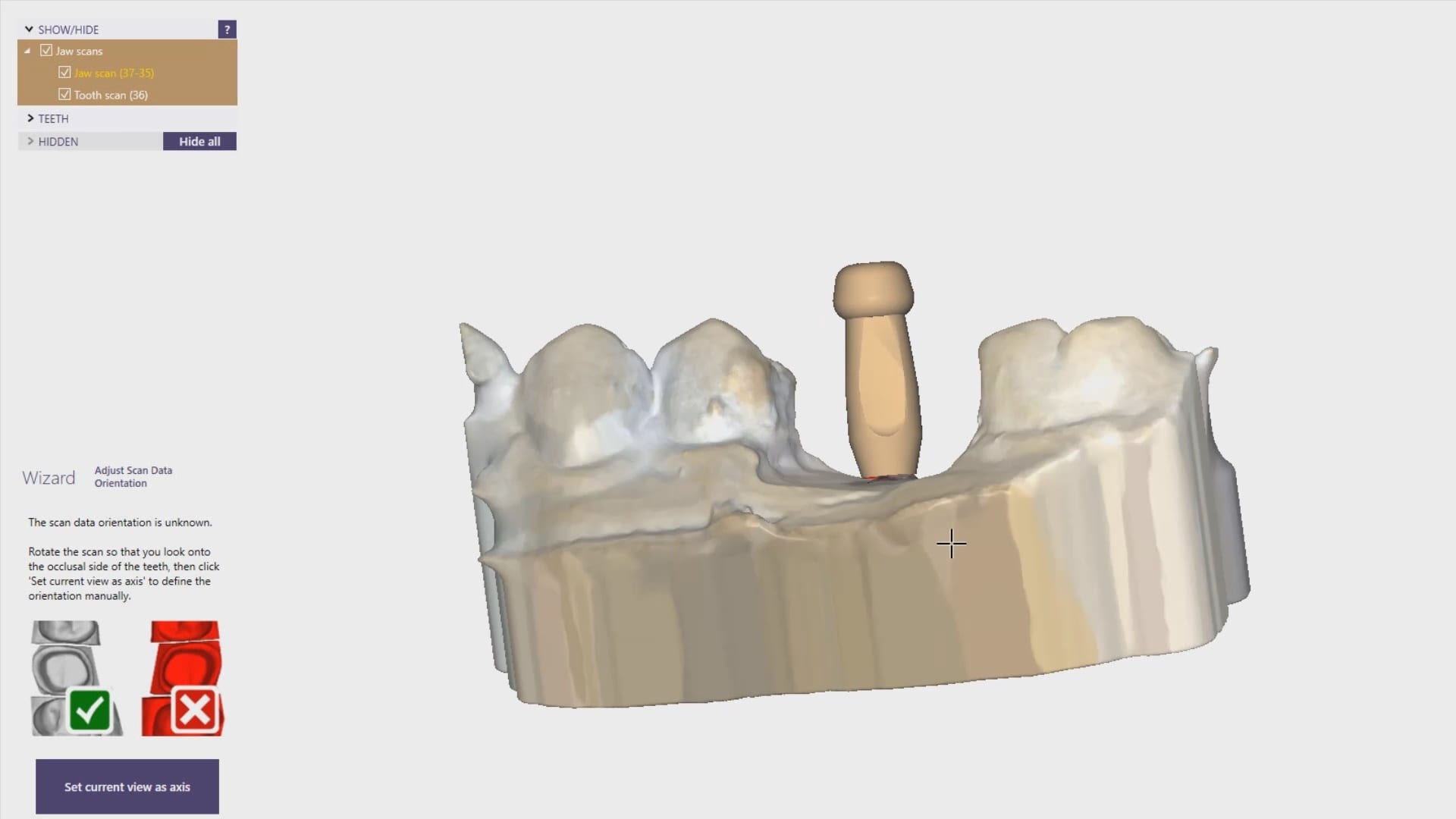

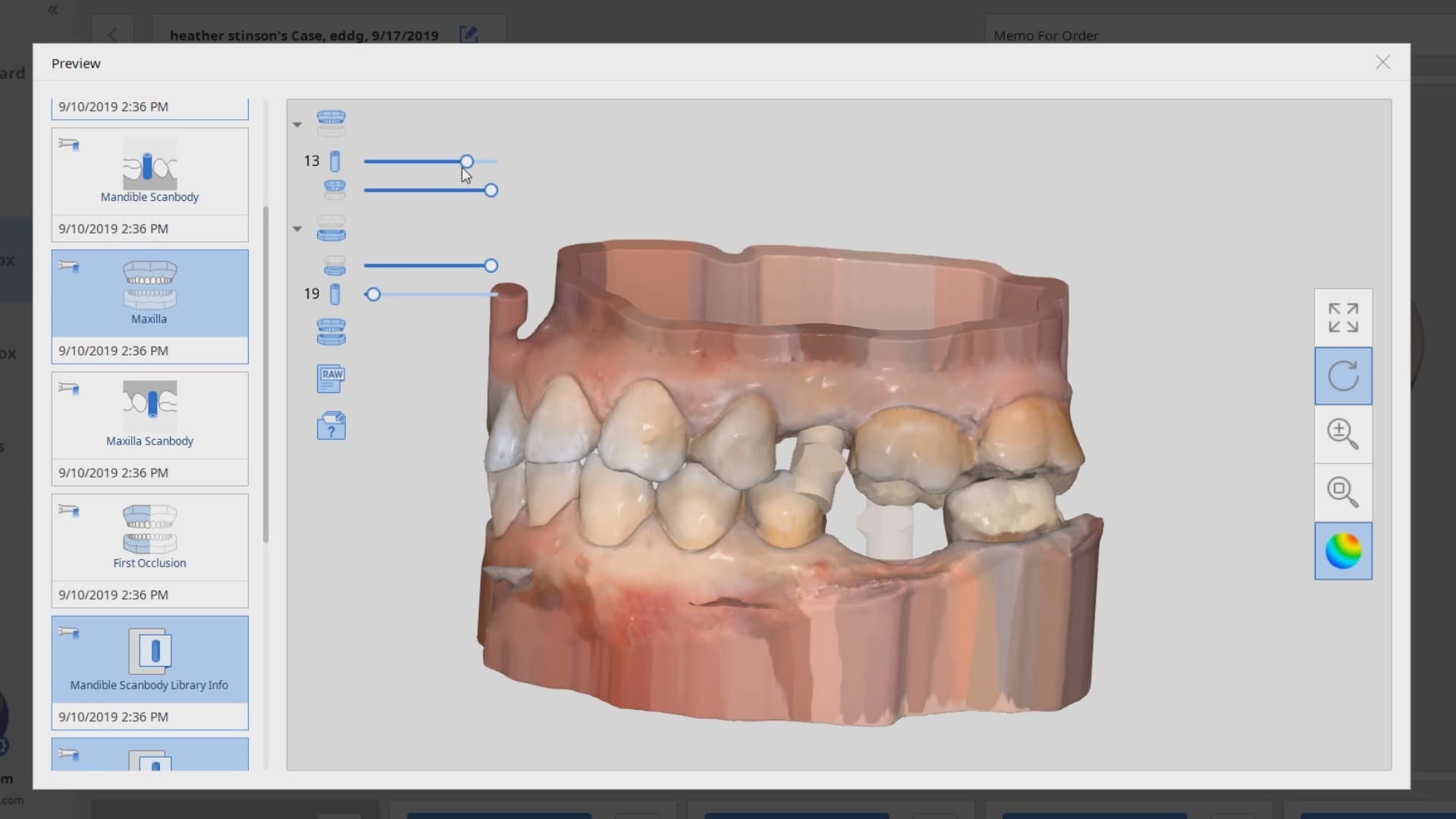

Once the data is imported into the library, you can preview it and incorporated into your own library of abutment. Please note that the abutment libraries are stored in the arch catalog boxes while the scanbody libraries are stored in the scanbdoy library, which means the abutment itself may be taken into consideration when capturing the buccal bite.

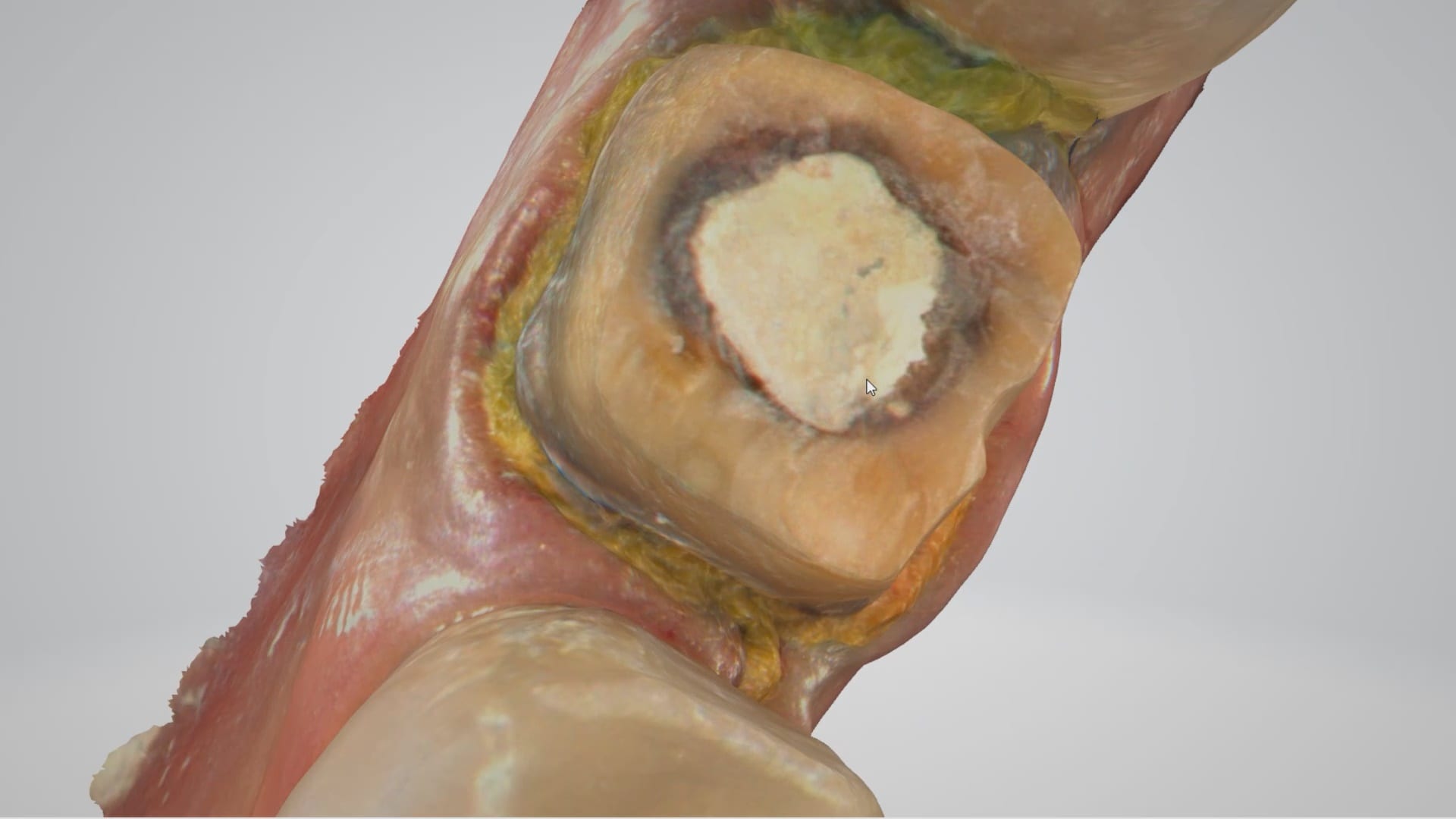

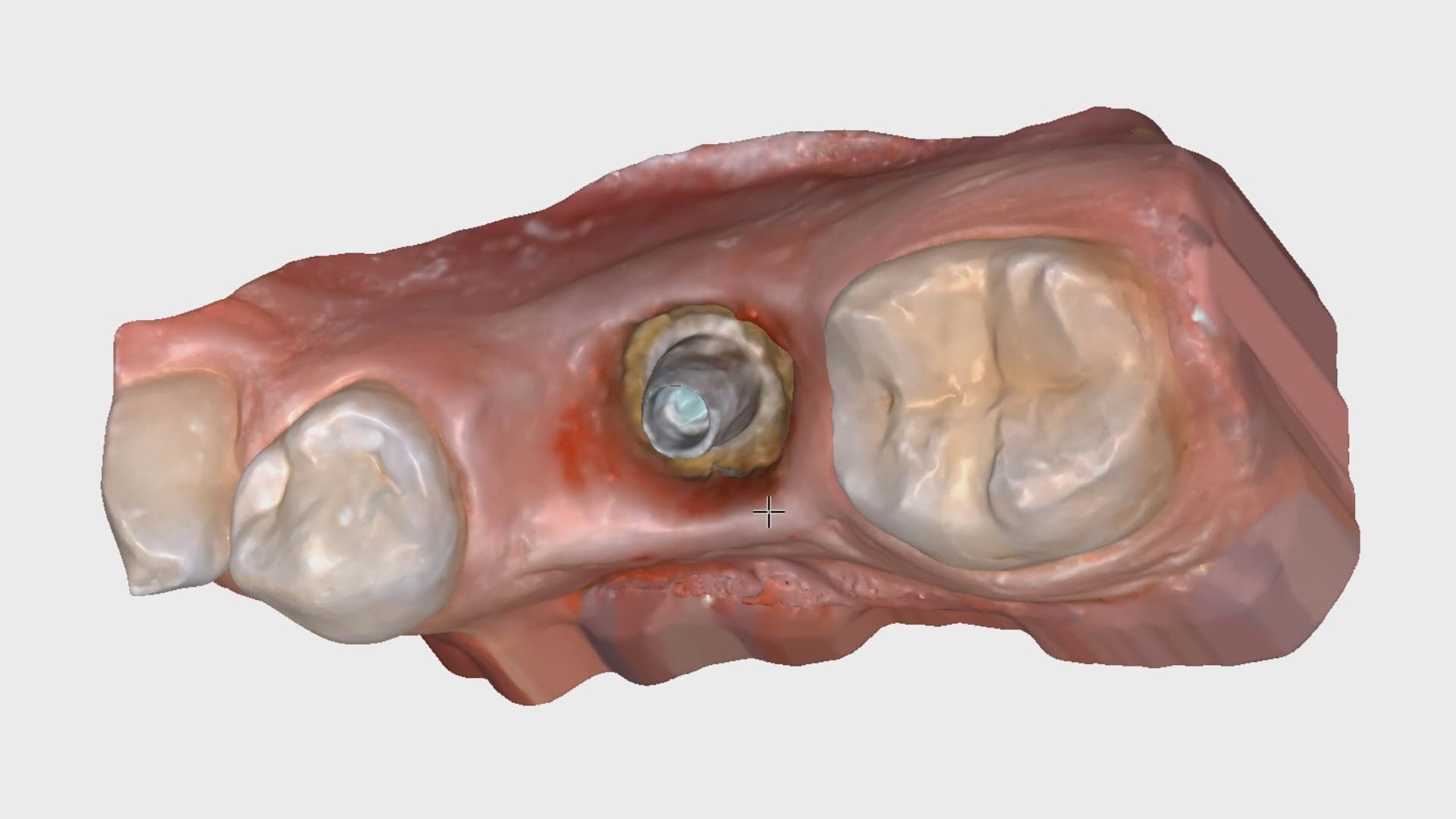

Once the abutment is identified in Medit it is directly transferred into cad software like exocad to proceed with design. Note in this footage how little of the physical abutment impression was brought into cad software. This greatly reduces errors and your imaging time intra-orally. You can also place a stock abutment and scan it in the same manner and be able to find margins with great ease without having to reach hemostasis or good tissue retraction

CLICK TO OWNLOAD THE MUA LIBRARY

DOWNLOAD THE BIOMAX NP LIBRARY

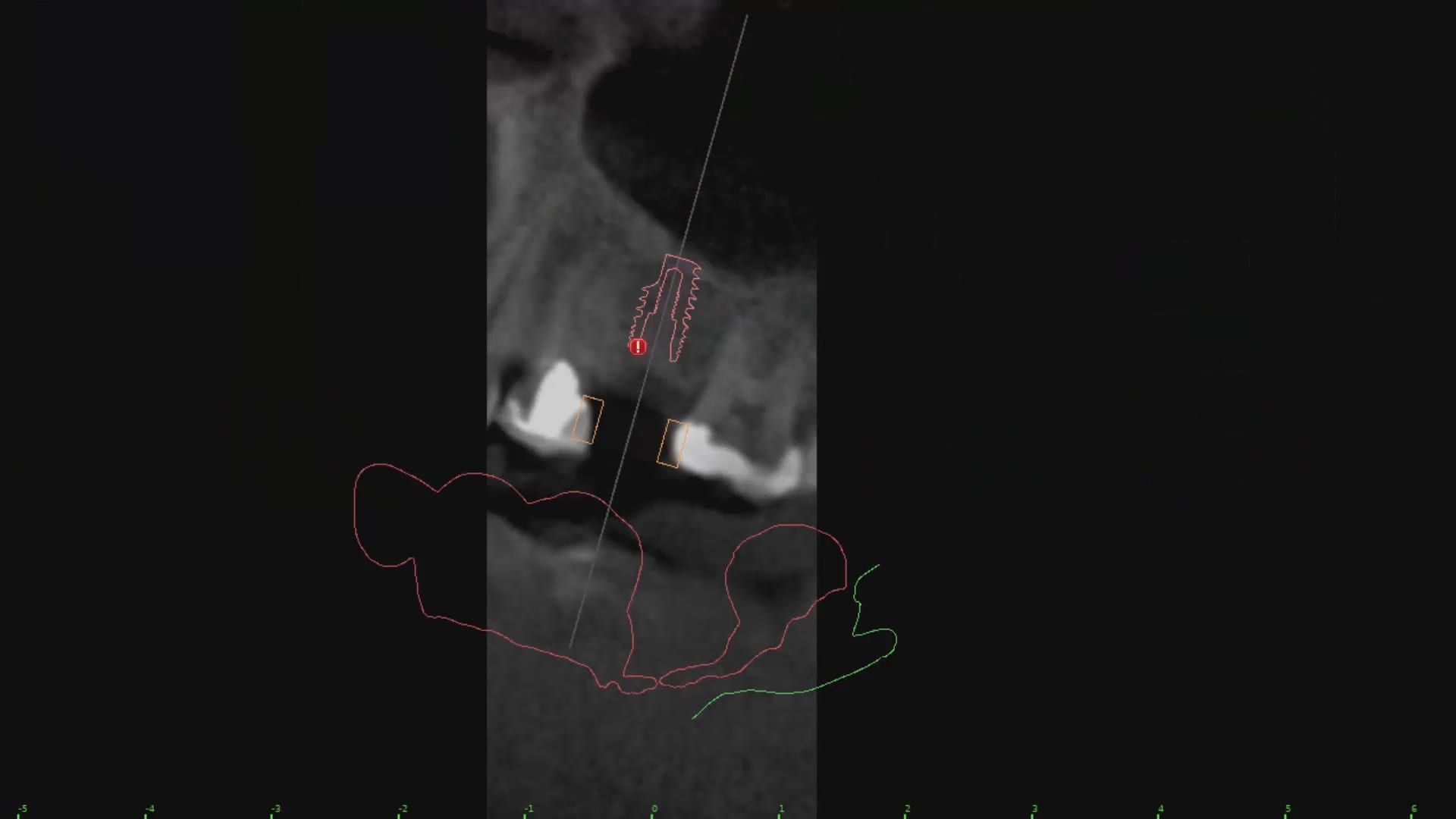

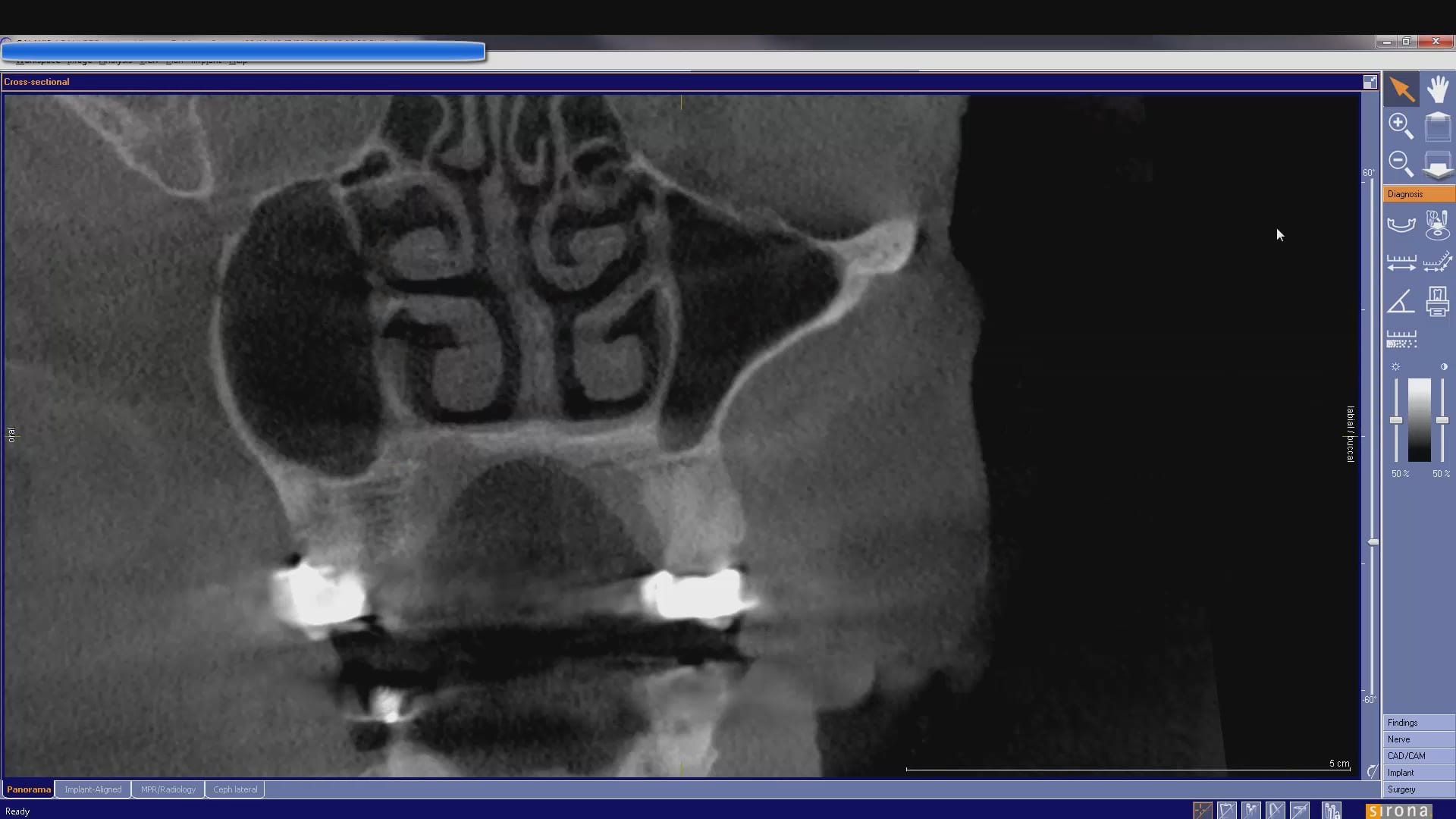

In this article we demonstrate how two separate implants are placed with guided surgery and then scanbodies are used immediately after placement to capture the location of the fixtures. While the patient is healing for the next 4-5 months, an upper tibase restoration will be fabricated with a lower custom titanium abutment. Digital impressions were taken with the Medit i500 for implant planning and Blueskybio software was used for the two surgical stents. Two 4.3 mm biomax implants were placed

While the patient was anesthetized, the edentulous arches on the patient’s left side were imaged. The bite was also taken, which ignores any information that is present in the scanbody catalogs. It is important to understand this as a new user because usually, the scanbodies are taller than the occlusal heights of the adjacent teeth. If these were captured in the wrong catalog boxes, the upper and lower jaw alignment could be mal-aligned

After sufficient anesthesia is achieved, the two surgical stents were seated and verified for fit. It is up to the clinician’s discretion to either lay a flap to access the area or to do the surgery flapless. Since the implant designs showed ample bone, and the fixtures were going to be placed sub-crestal, a tissue punch technique was used here as the area will granulate in. At uncovery, a flap can be used to advance the tissue to the buccal to enhance keratinized tissue appearance

One of the greatest benefits of digital dentistry is that you can capture parts of a model independent of time and sequence. In this particular situation, we opted to capture the scanbody for the upper arch even before the lower arch received the implant.

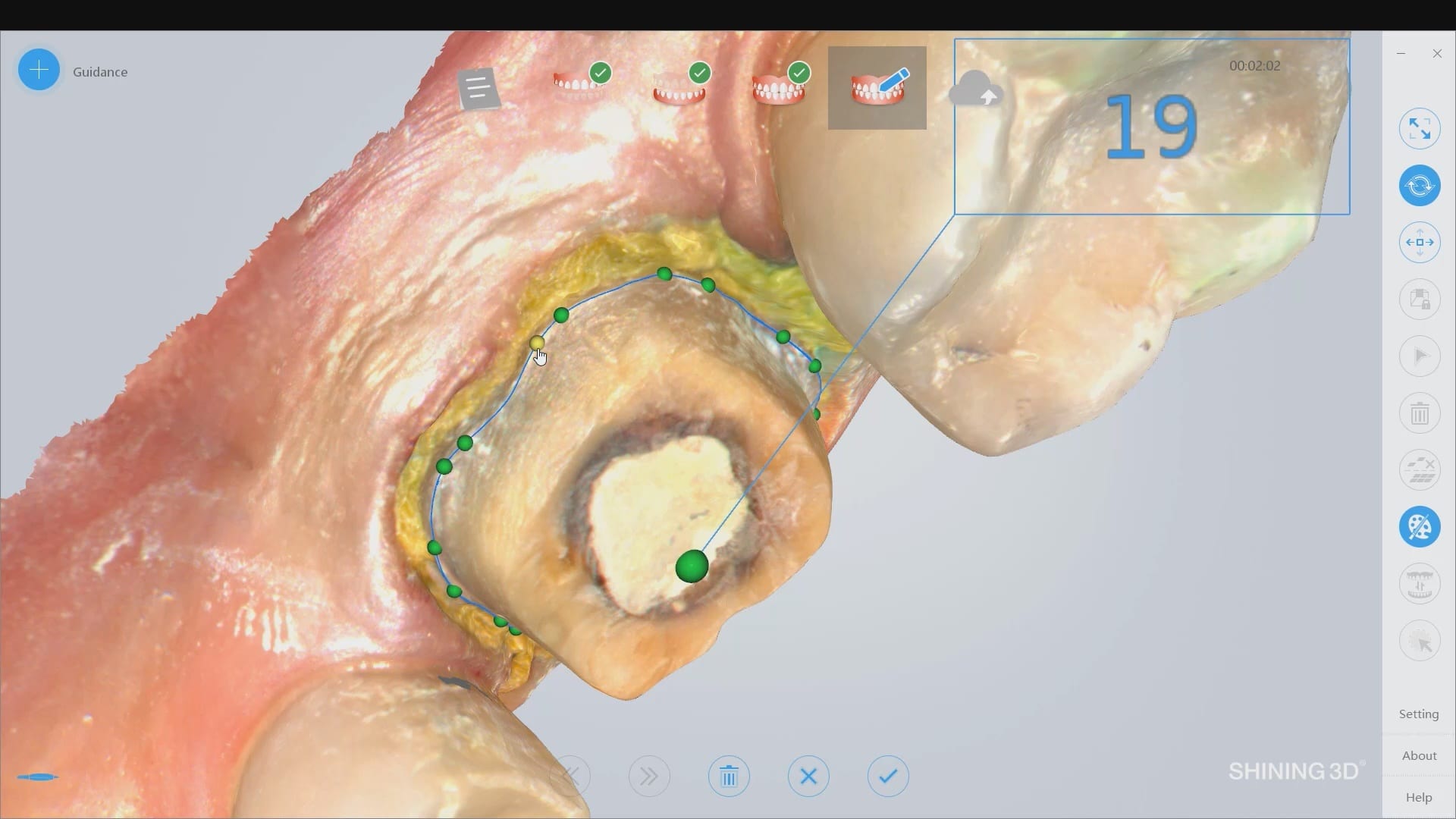

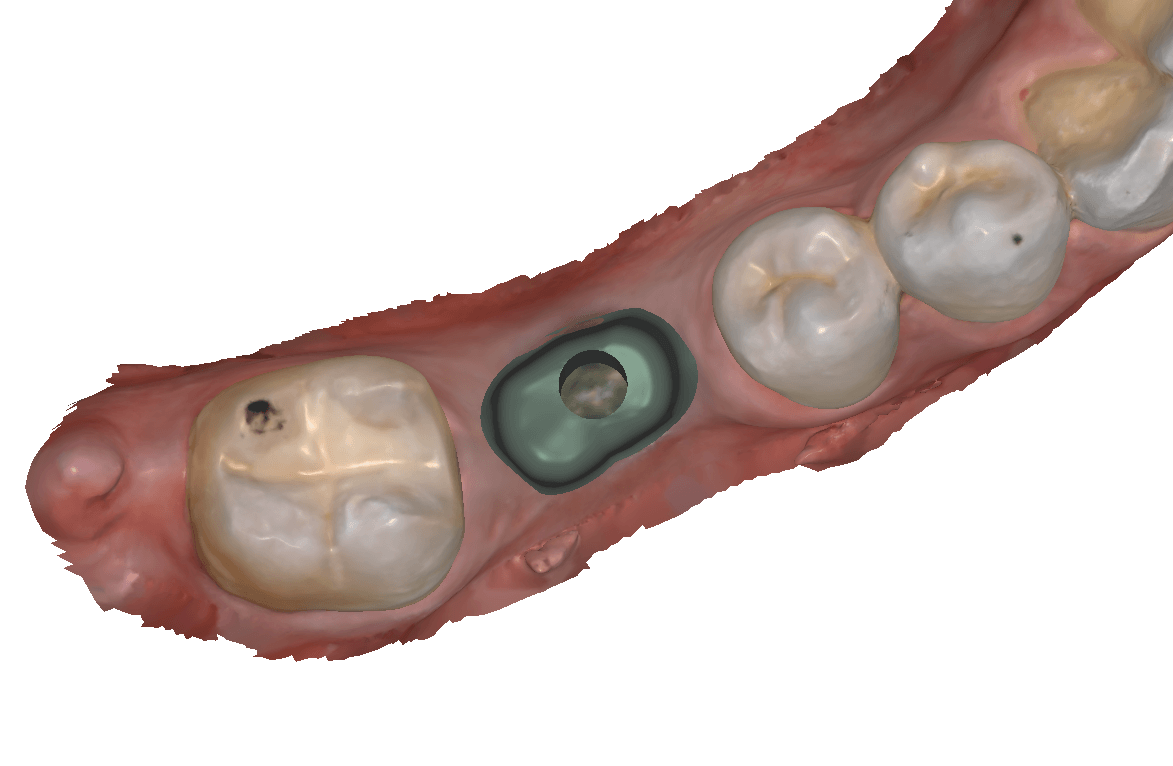

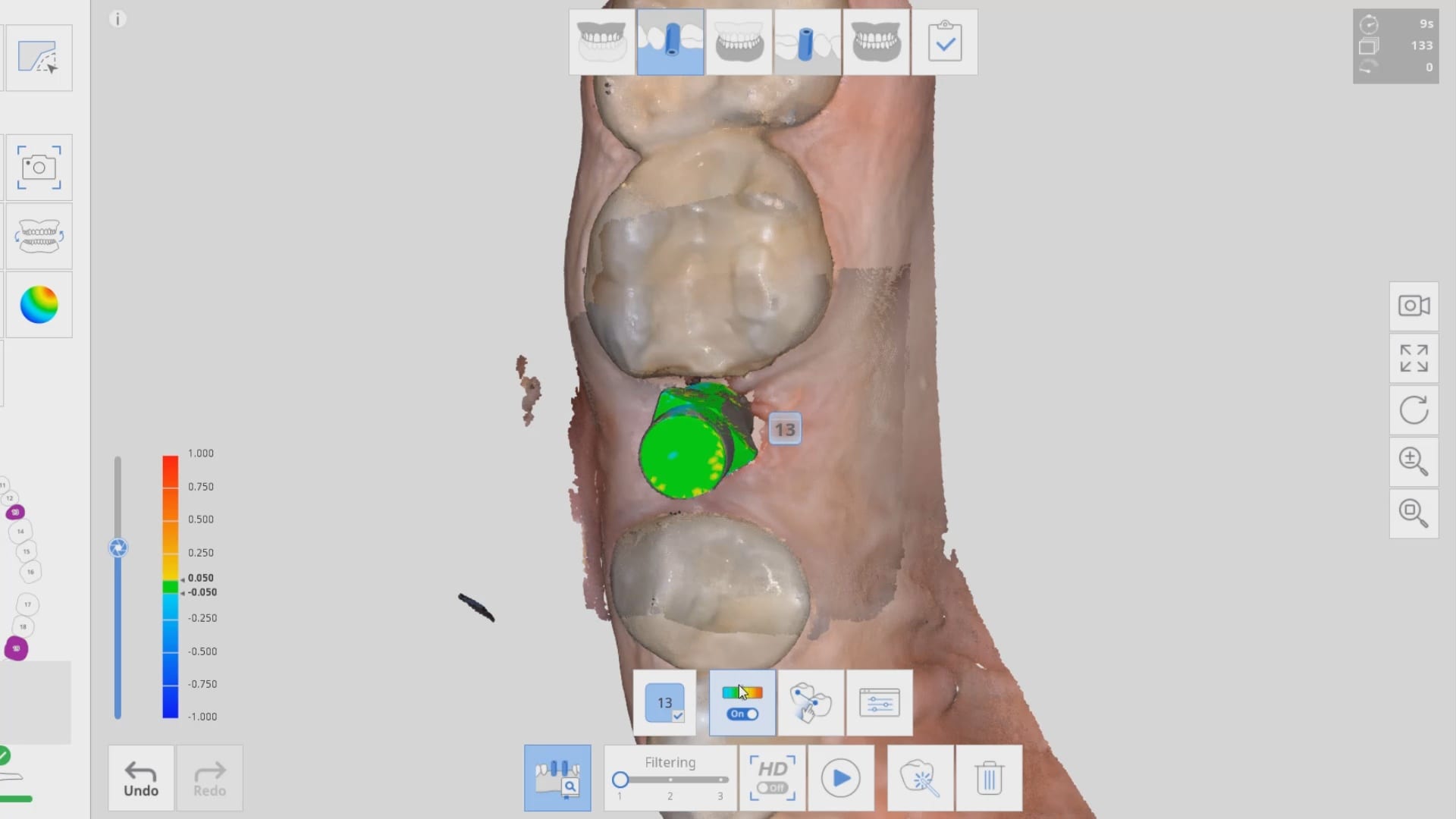

We utilized Medit i500’s Artificial Intelligence to spot and mark the scanbodies. Once these data points are plotted and synchronize with what appears intra-oral, you no longer have to worry about distortion or artifact in the scanbody itself. Color coding is a good indication of an accurate identification of the DESS scanbodies.

The significance of these identified scanbodies is that you can directly import them into the cad software and the fixture locations are readily identified and the design process can proceed.

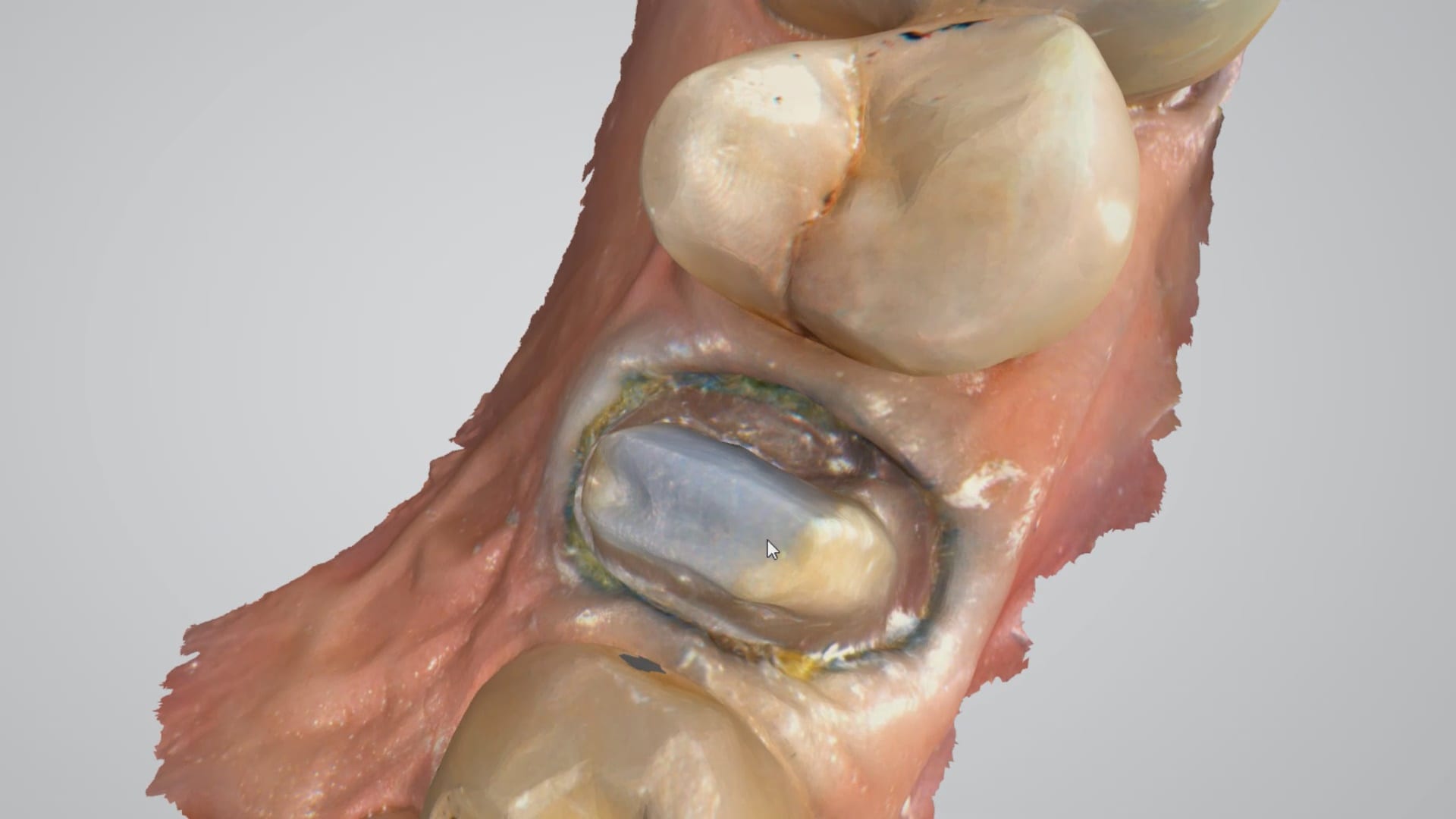

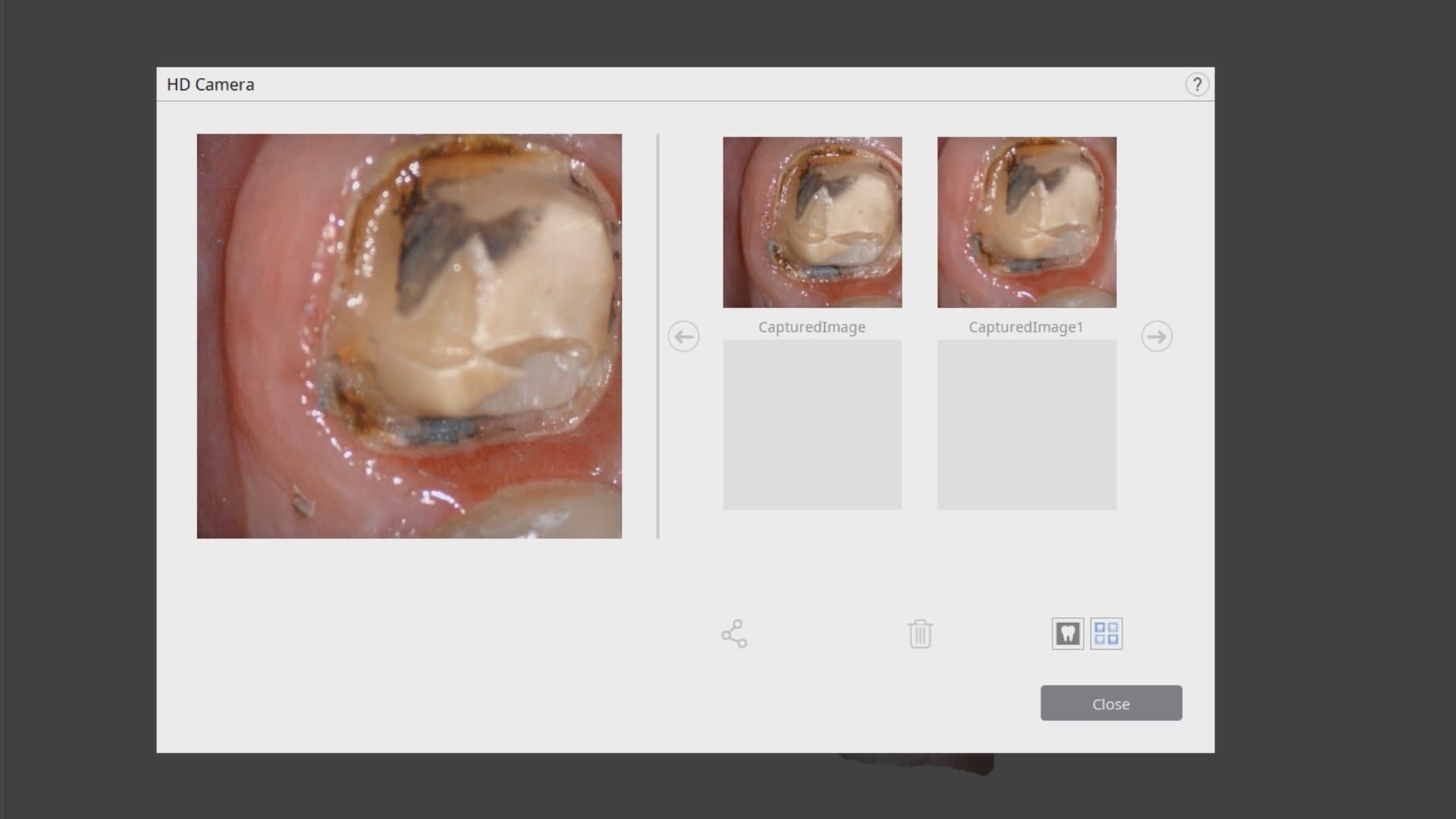

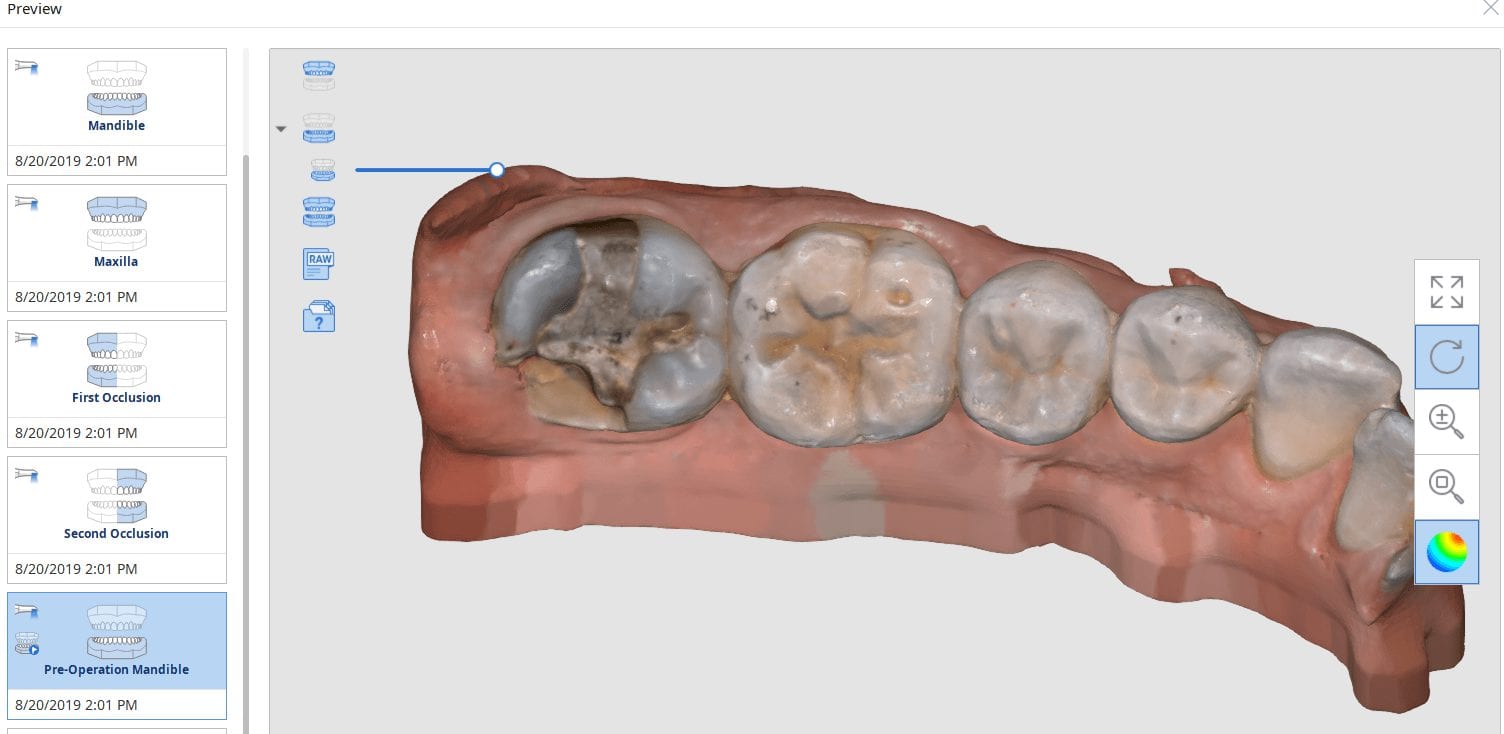

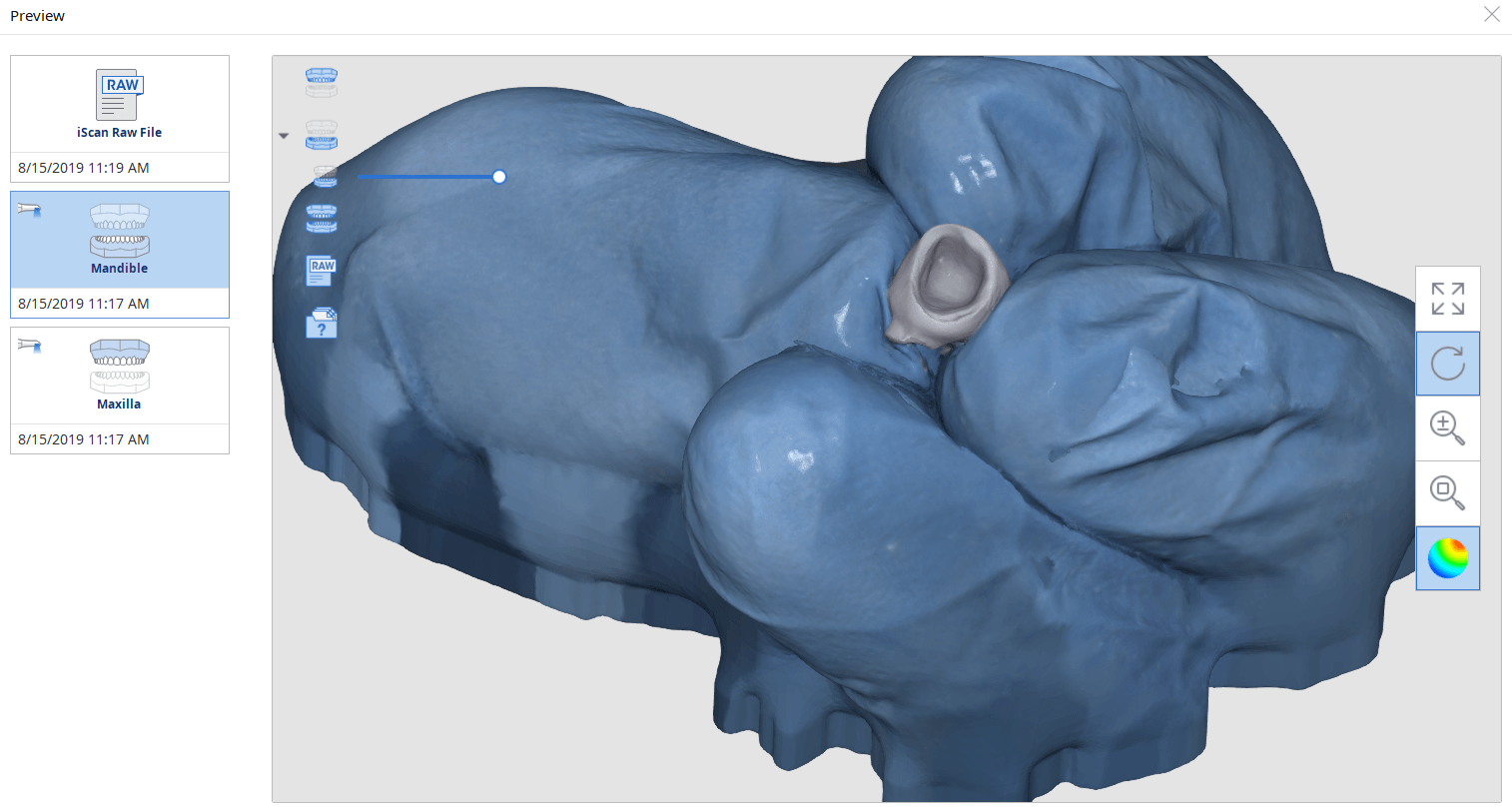

In this case presentation, we utilize the medit i500 to image the pre-existing crown and to fabricate a restoration that is a replica of the pre-existing condition. The patient was advised that the recurrent decay was in close proximity to the canal space and that endodontic treatment may be a possibility. The CBCT showed no evidence of any peri-apical radiolucency and the premolar tested vital prior to treatment

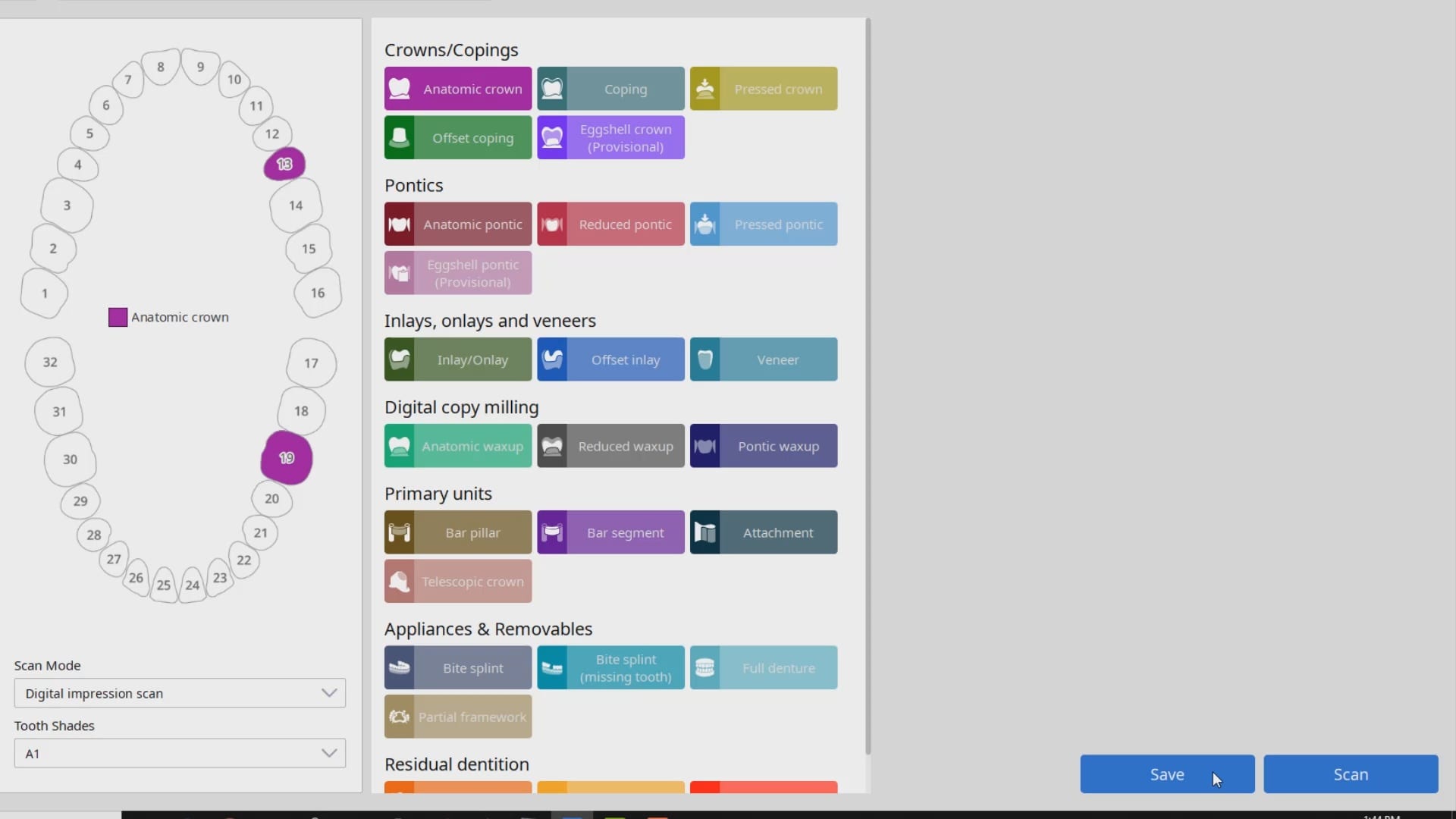

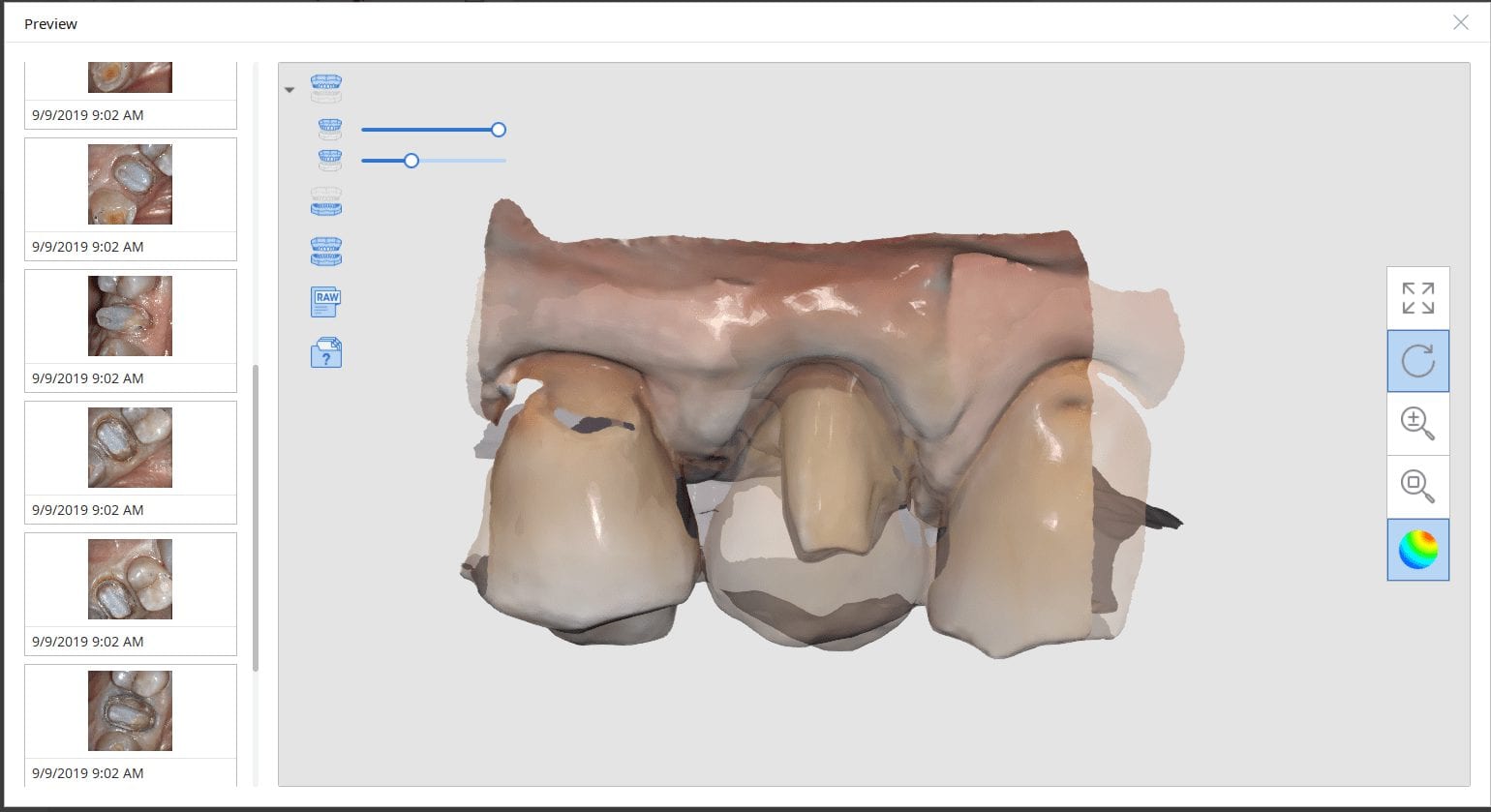

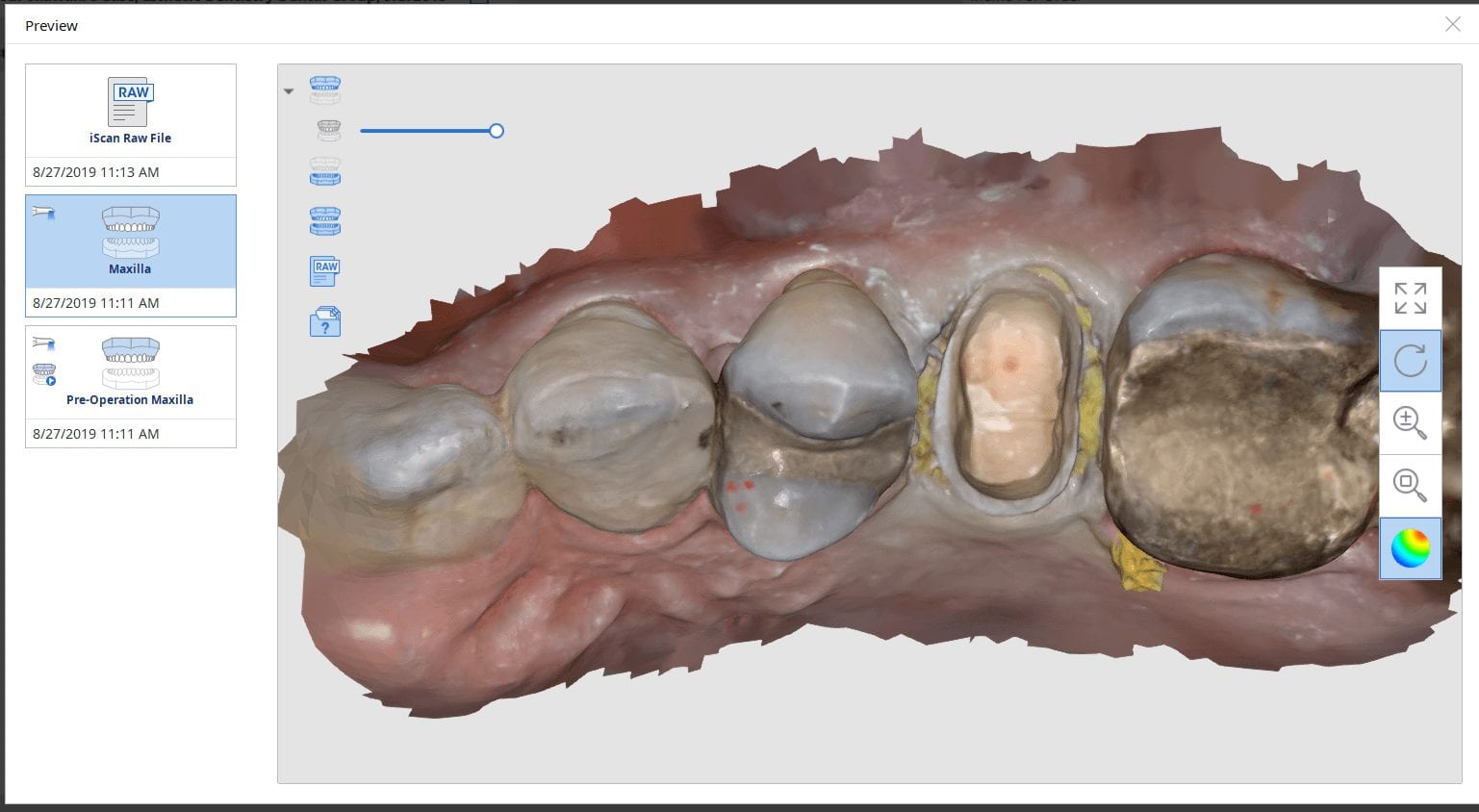

Case set up involved imaging the pre-existing condition in the pre-op catalog box. Excess information was cropped to reduce file size. The data was then copied to the maxillary arch catalog box and the area to prepared was edited out in preparation for final optical impressions.

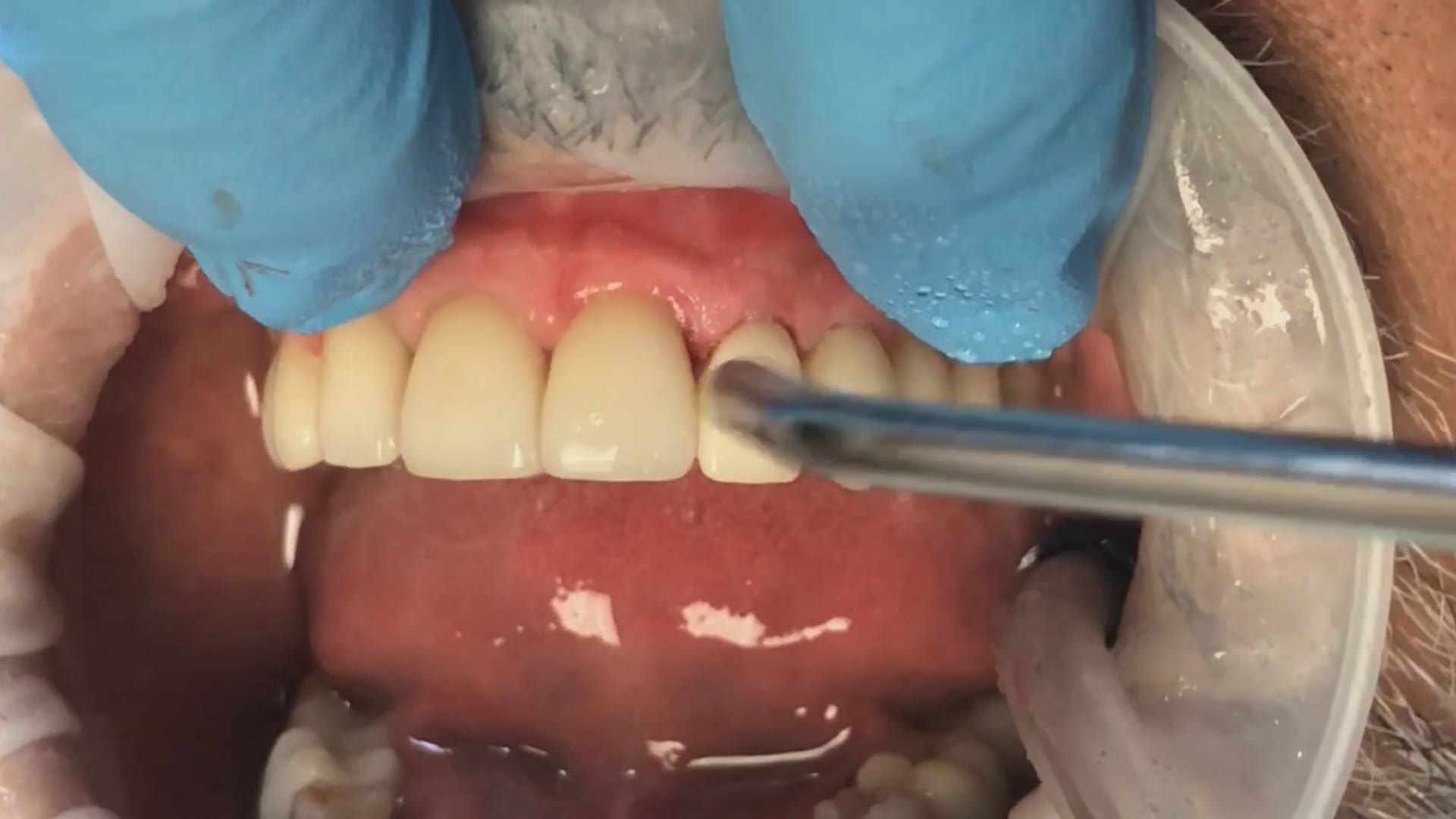

Immediate Post Op

The remaining decay and previous build up material was removed just prior to bonding the restoration with NX3 dual cure resin cement so the dentin was exposed for the least amount of time possible.

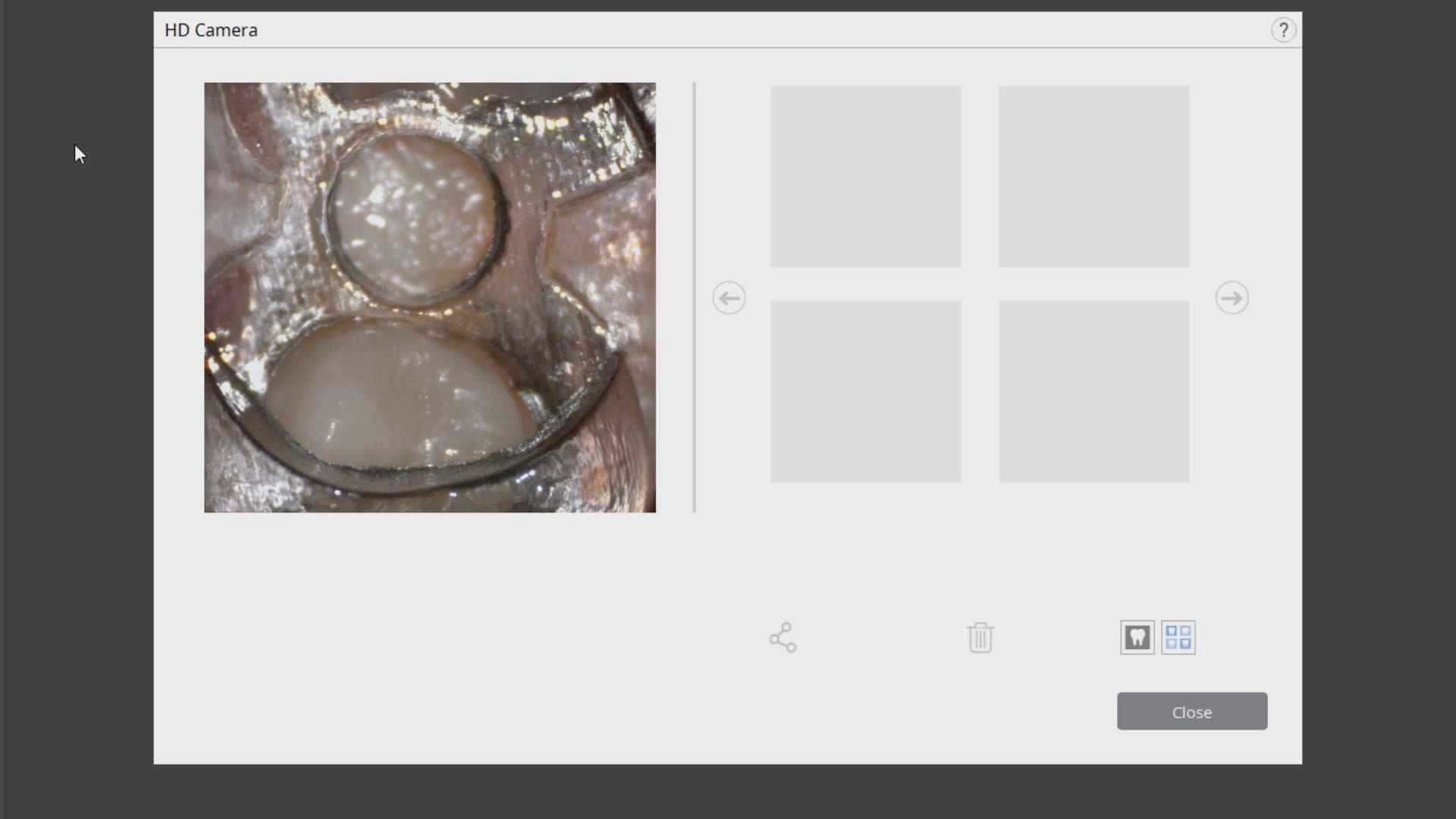

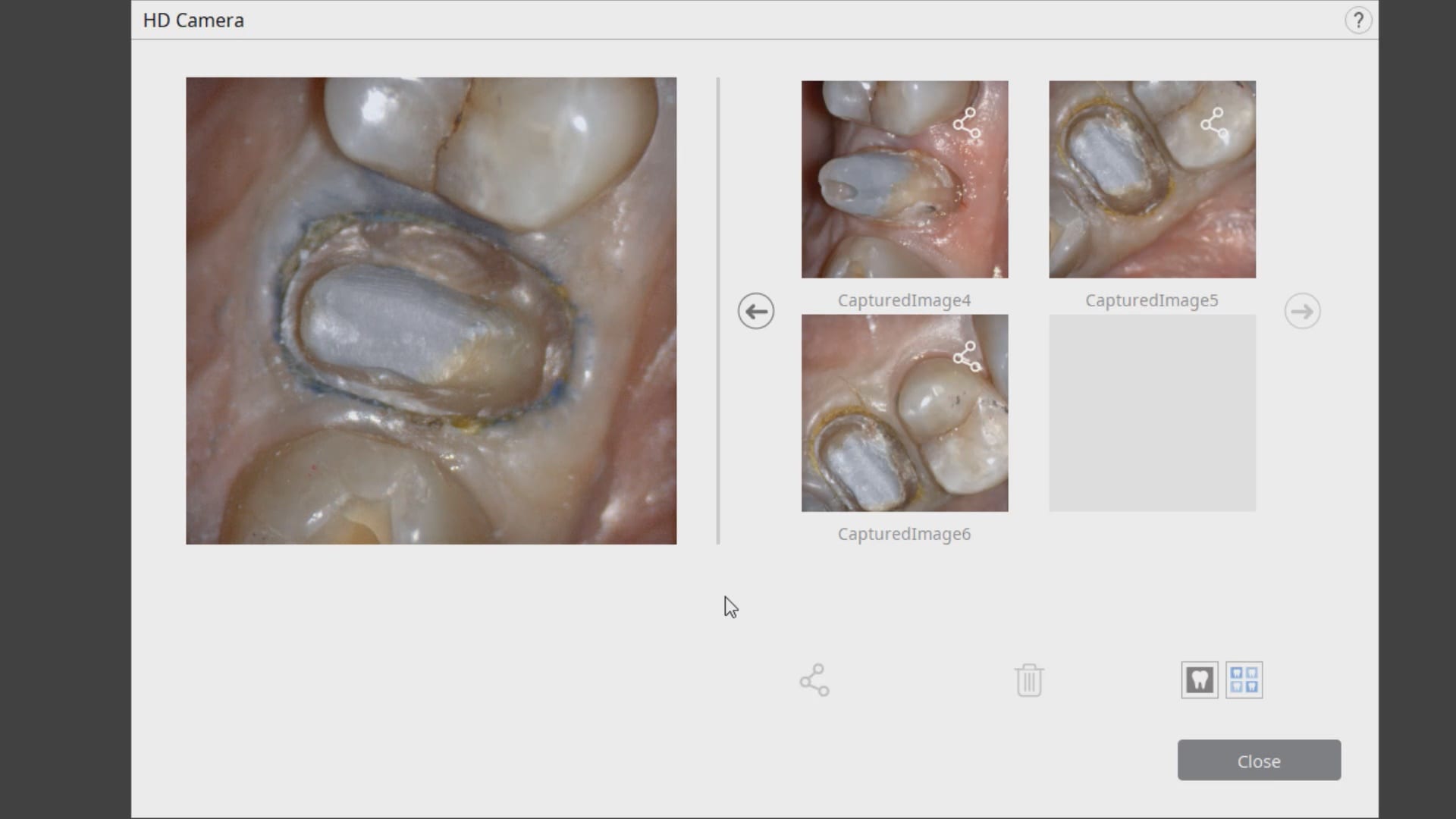

At CAD-Ray, we are big proponents of open architecture and the doctors control the flow of their patients’ digital data, whether it is a CT scan or an digital impression system. We have put the Aoralscan through a battery of tests. For single unit, it delivers on quality that equals any other scanner on the market. We were particularly impressed with this deep margin and how well the graphics could differentiate tissue from tooth structure on the distal of the prep

click to download the OBJ file of this case (note: we only scanned to pick up data for the margins)

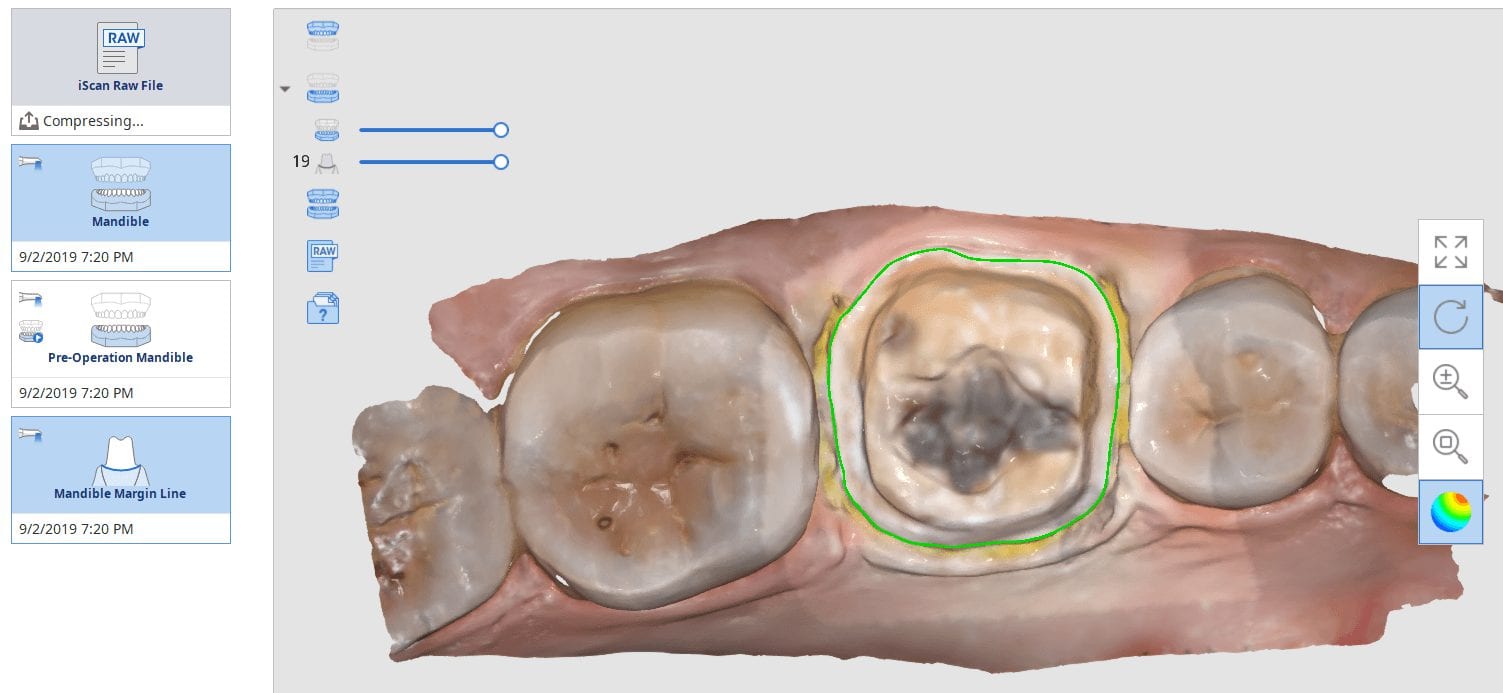

In this case presentation, we feature a crown that needs to be replaced due to open margins and recurrent decay.

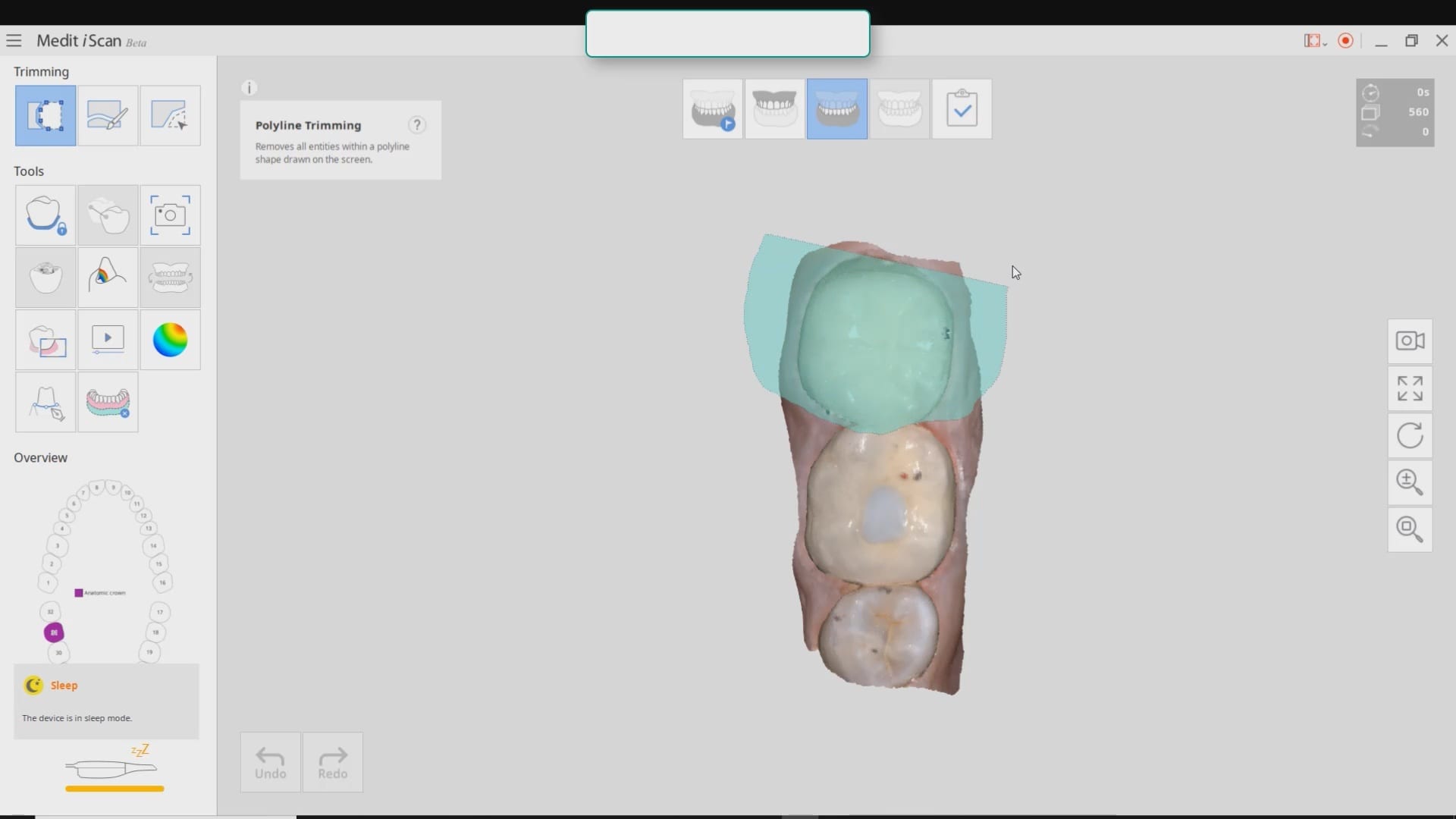

With the Medit i500, after the patient is anesthetized and the area is isolated, the pre-existing crown is imaged in the pre-op catalog box. The area to be prepared is cropped out in anticipation of the imaging the modified preparation.

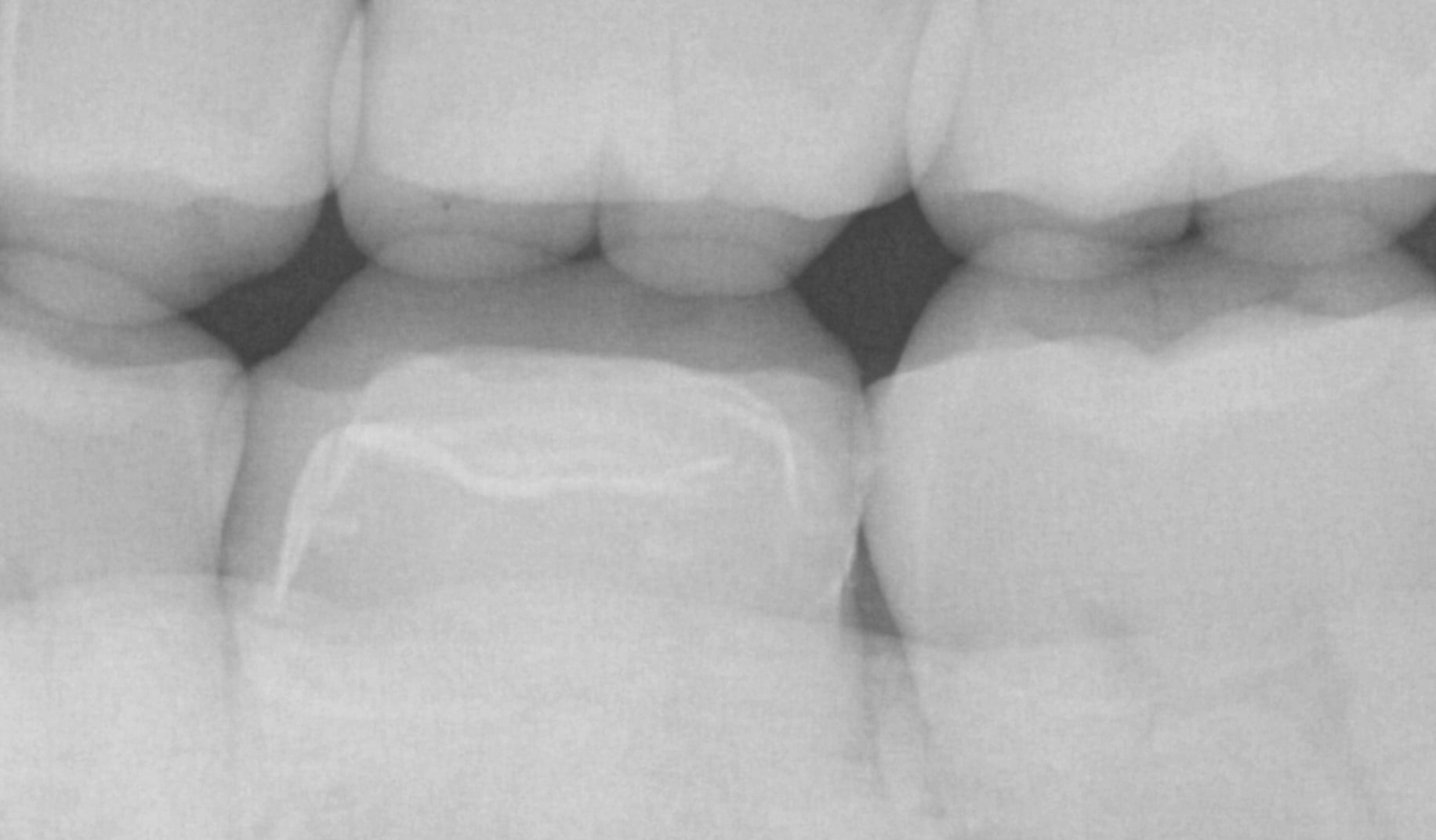

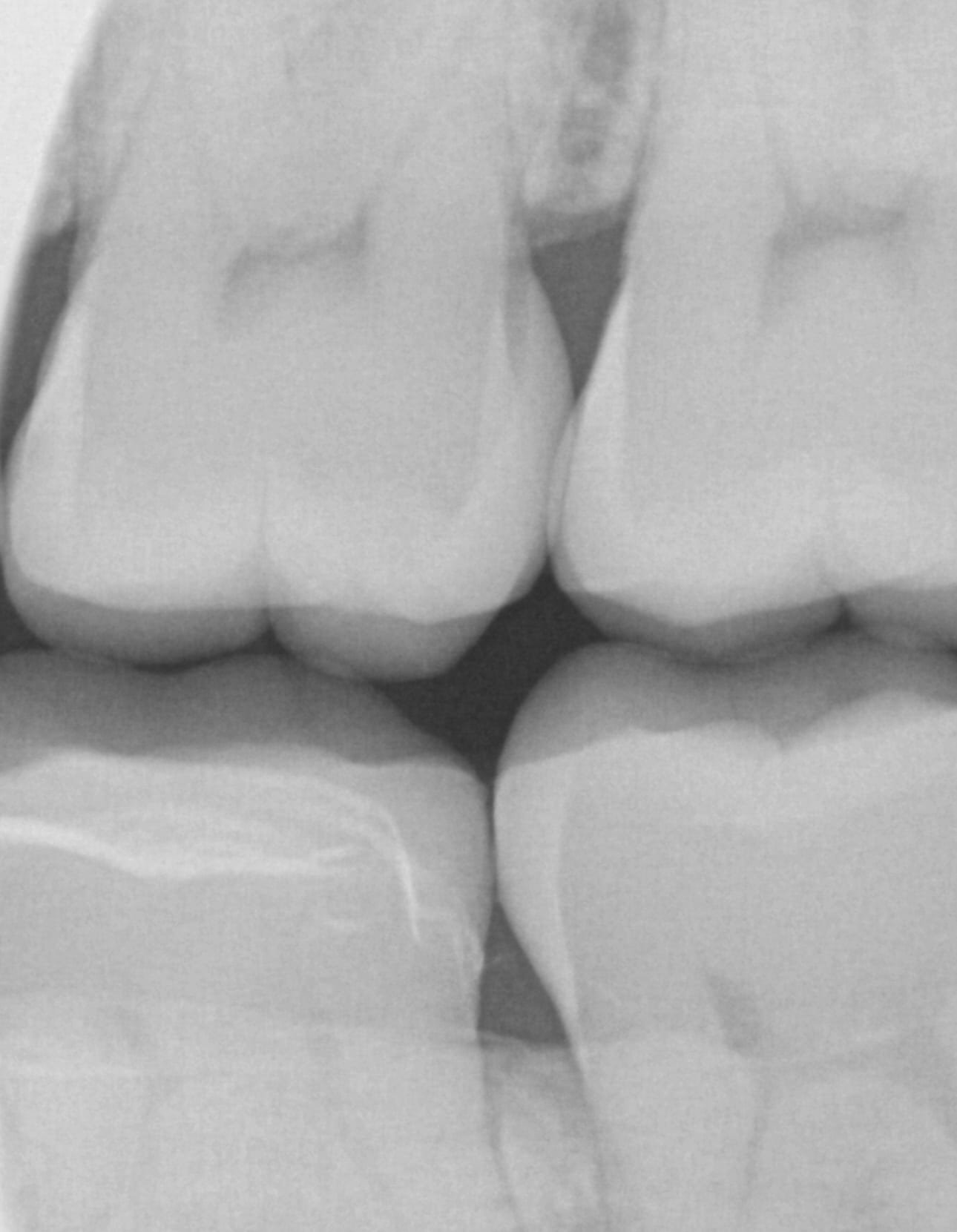

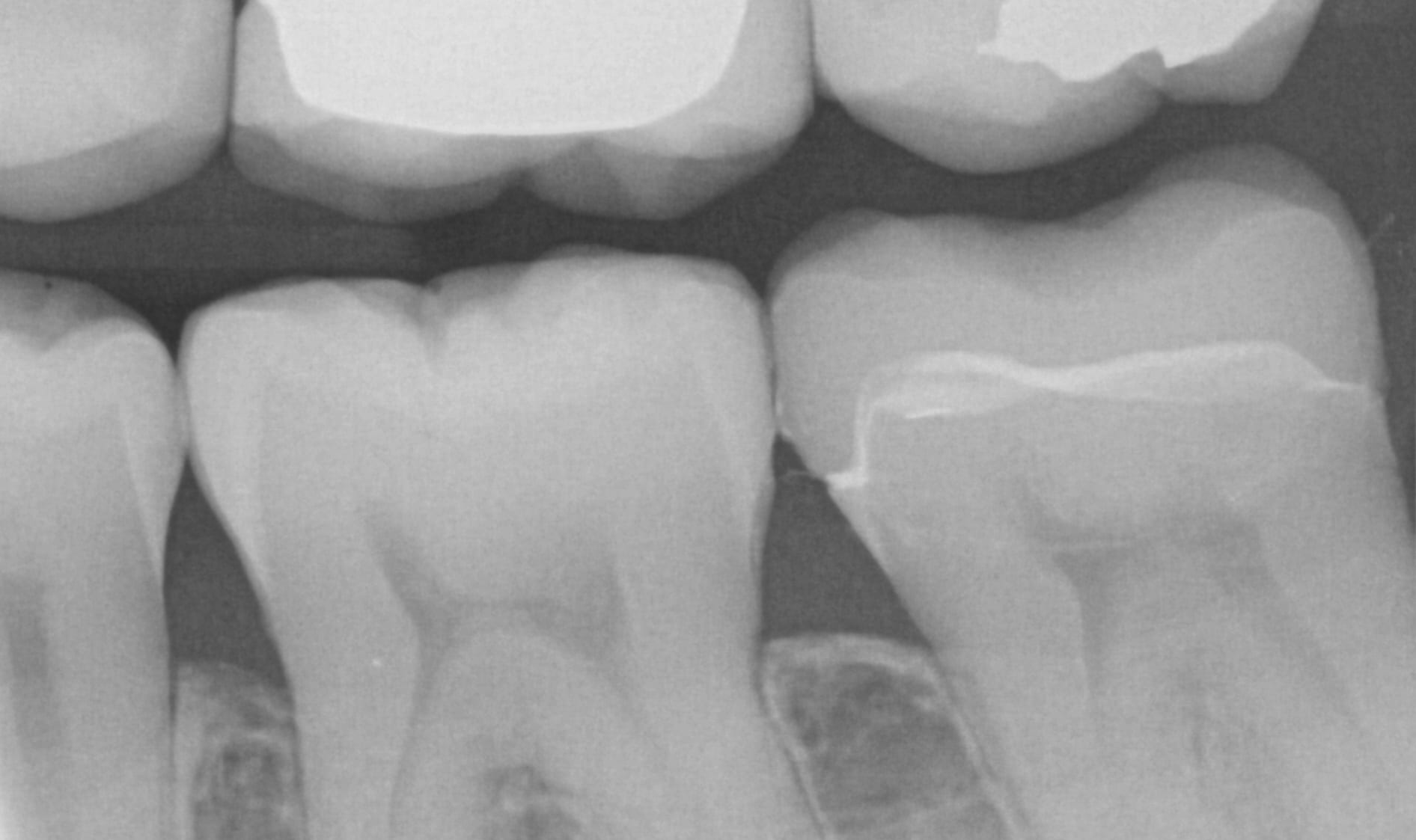

Once the crown is removed, expasyl is packed into the sulcus with a Number 2 cord. With the pre-op bitewings X-ray it was readily apparent that the tissue should be positively displaced in order to capture the margins. It took two layers of cord to achieve hemostasis for imaging with the Medit i500.

While placing the margin in the native imaging software, it was noted that some tissue was obscuring the margin on the lingual side. The area was isolated both clinically and in the software. It was cropped out and filled in with ‘good data’ after proper protection of the adjacent teeth and margins so that we did not obscure their geometry.

Once the margins are identified and the case is processed it is automatically imported into exocad for design and then sent to the Imes Icore CORiTEC Once for manufacturing. The emax restoration was tried in and then delivered after crystalization.

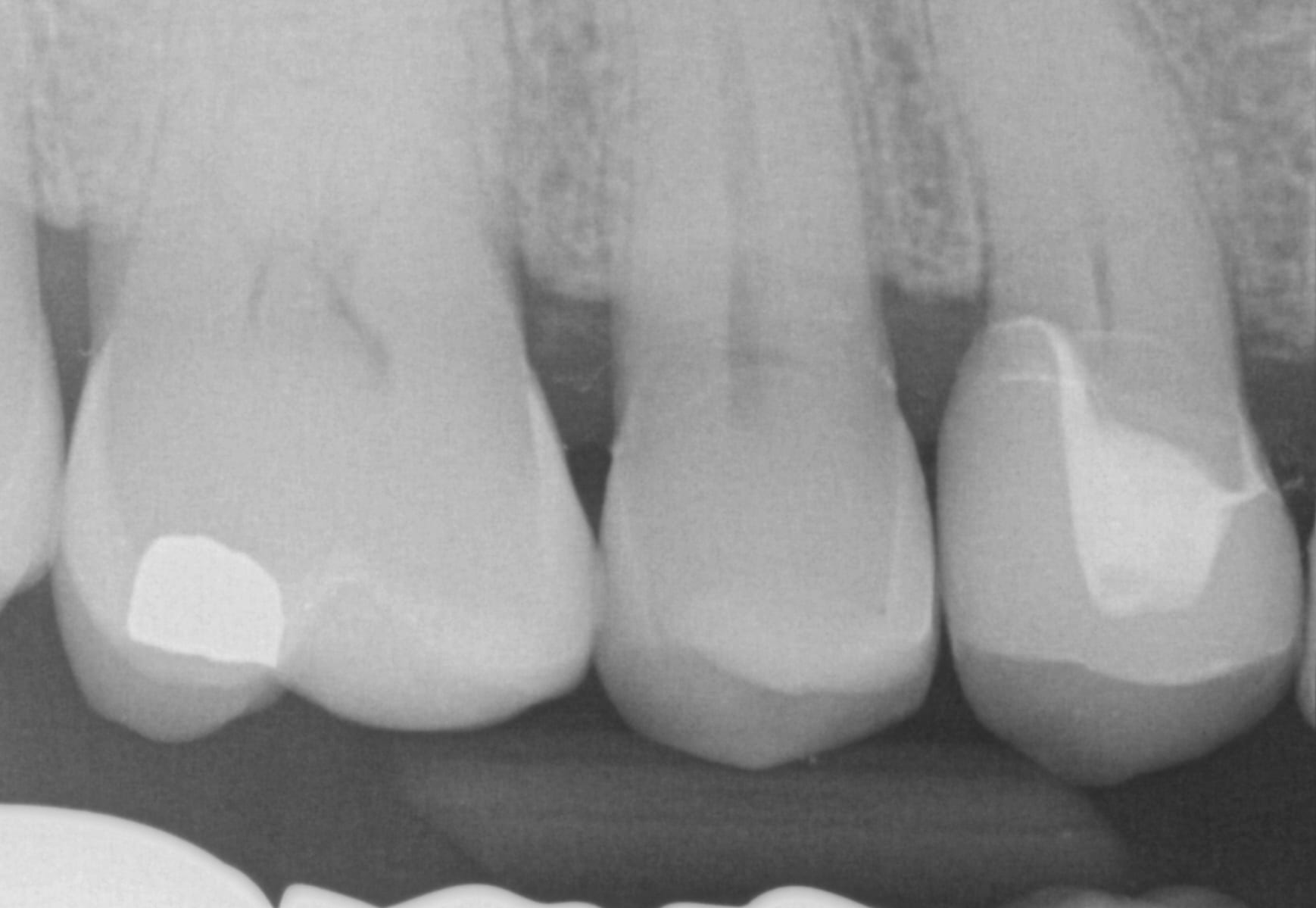

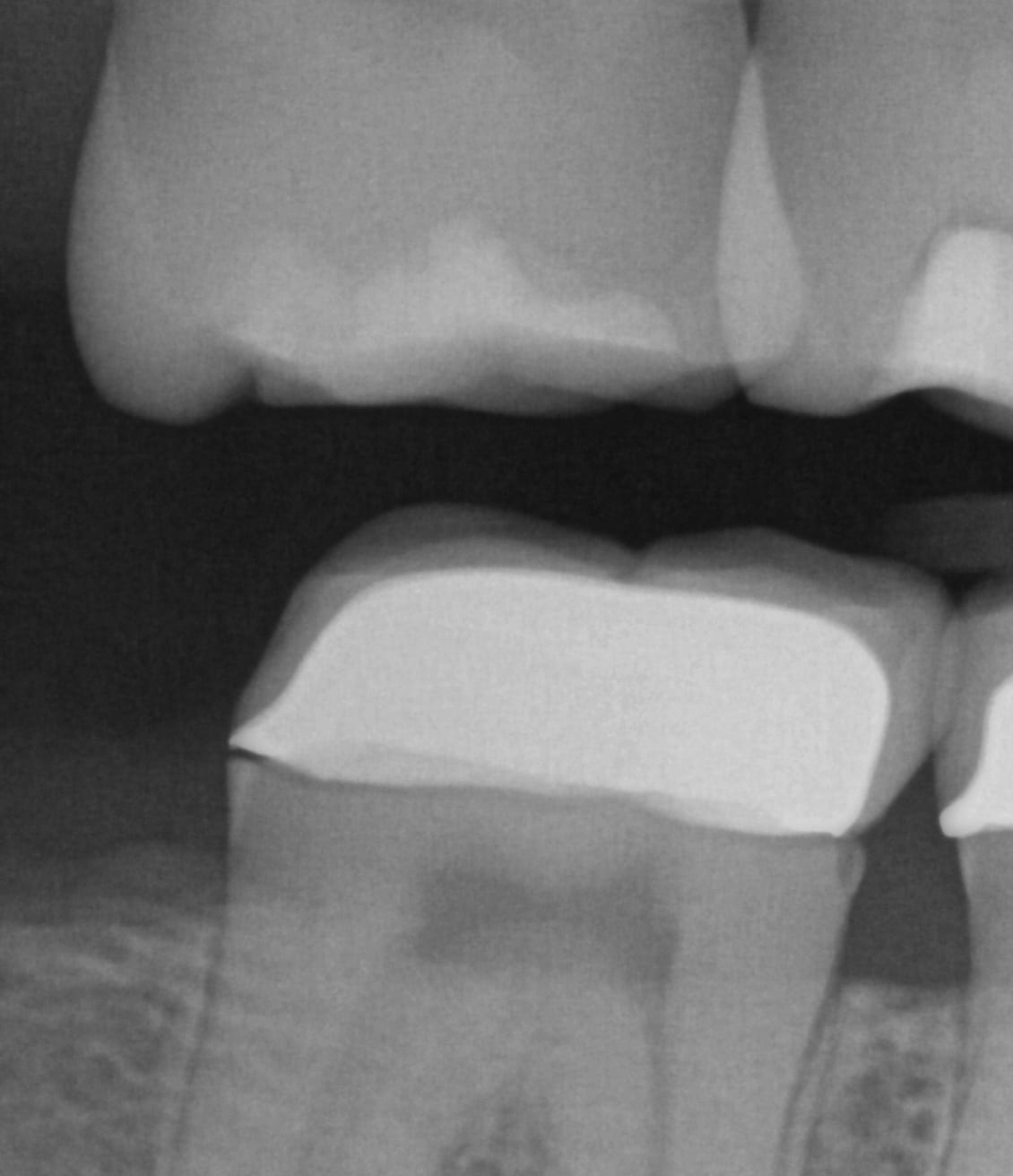

Immediate Post-Op X-Ray taken to verify seat and no excess resin cement

Click Image to Download the OBJ Files And design Along

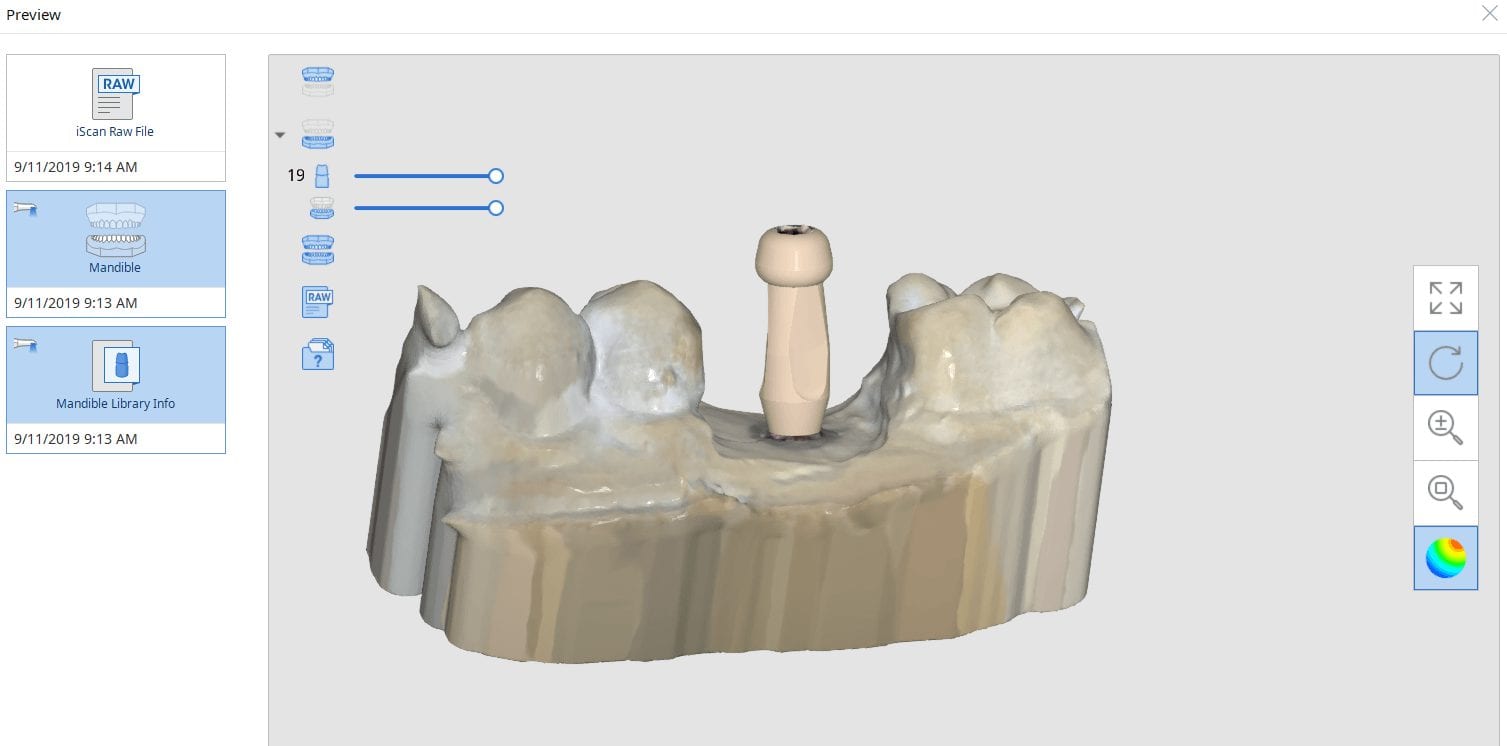

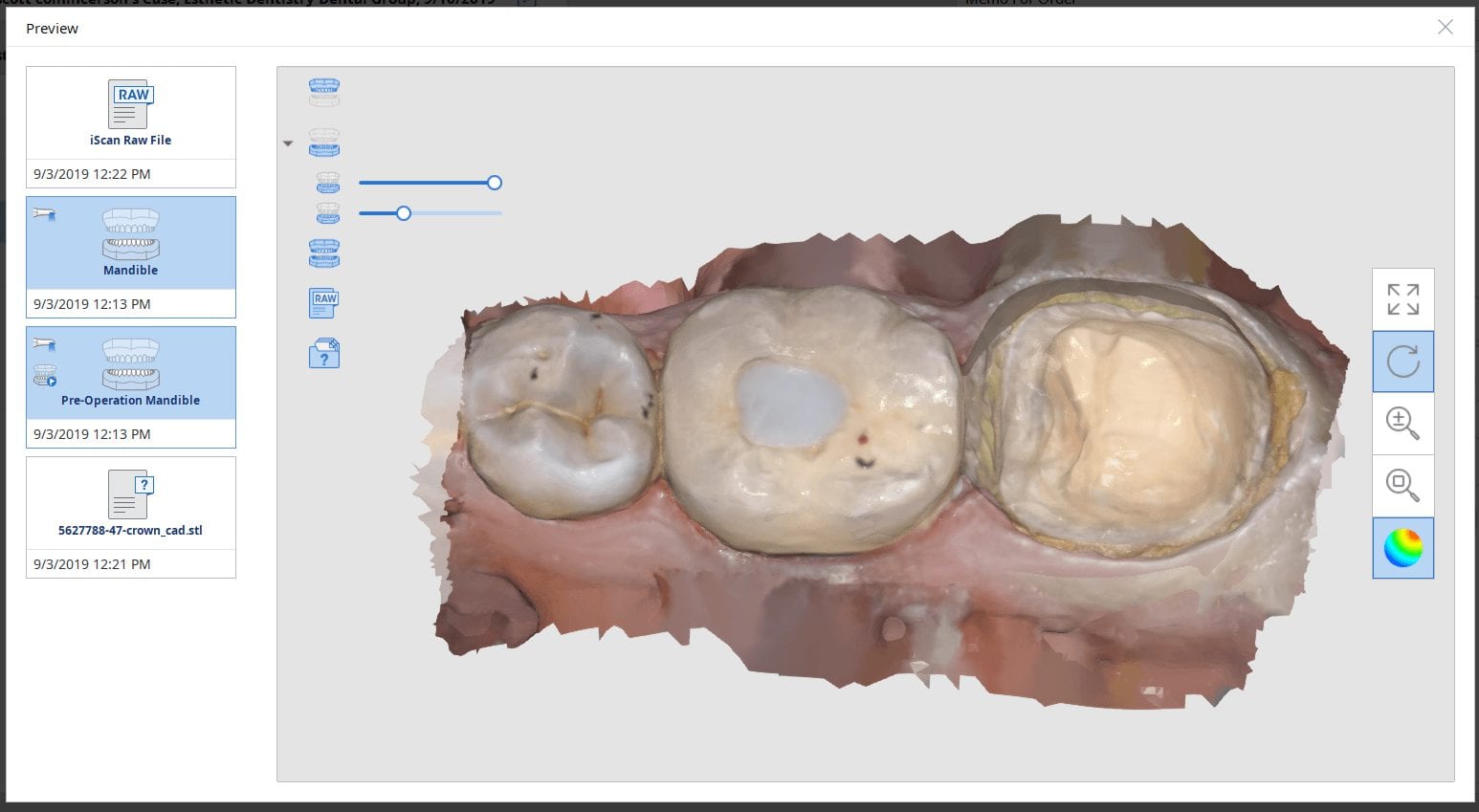

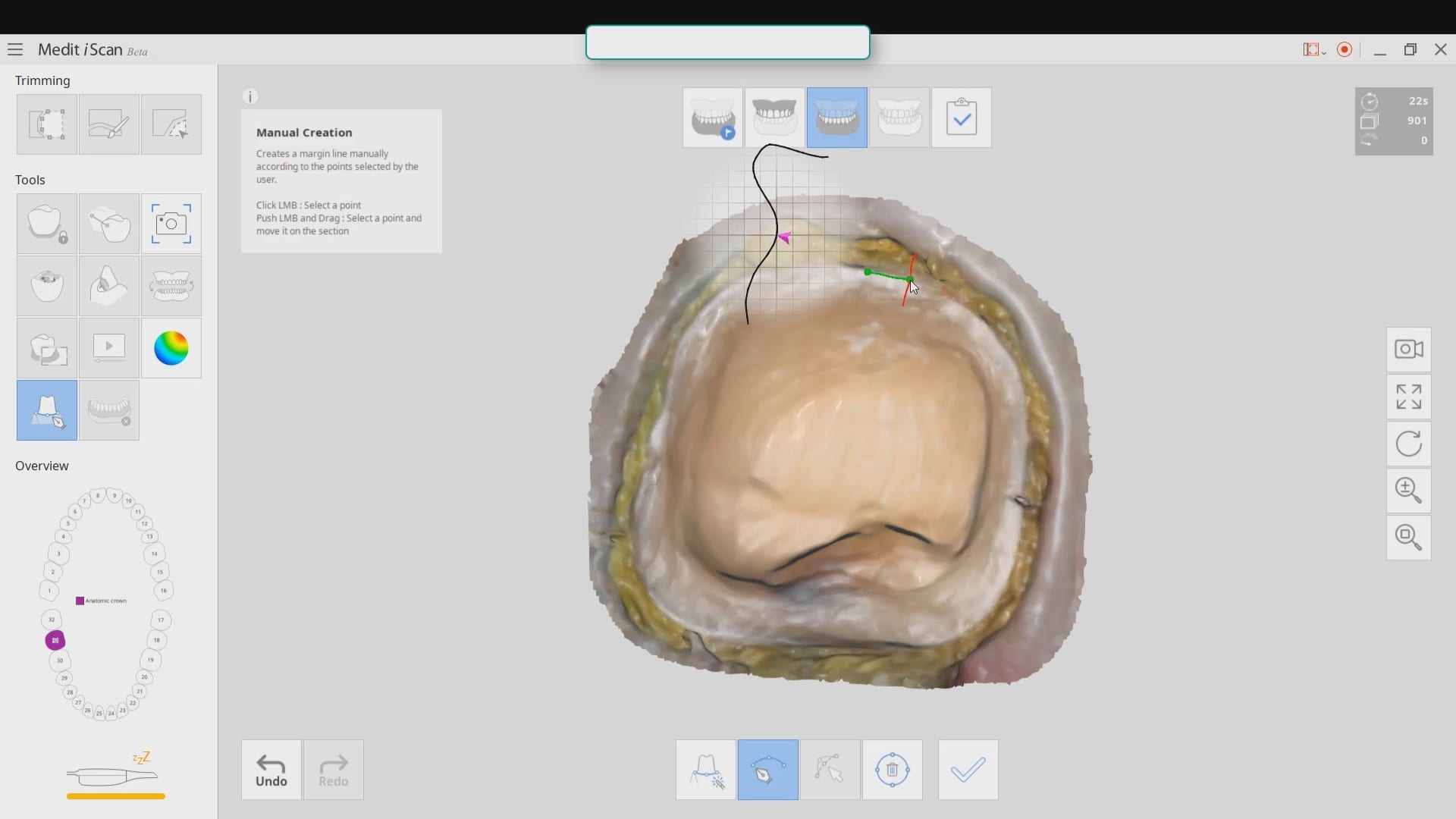

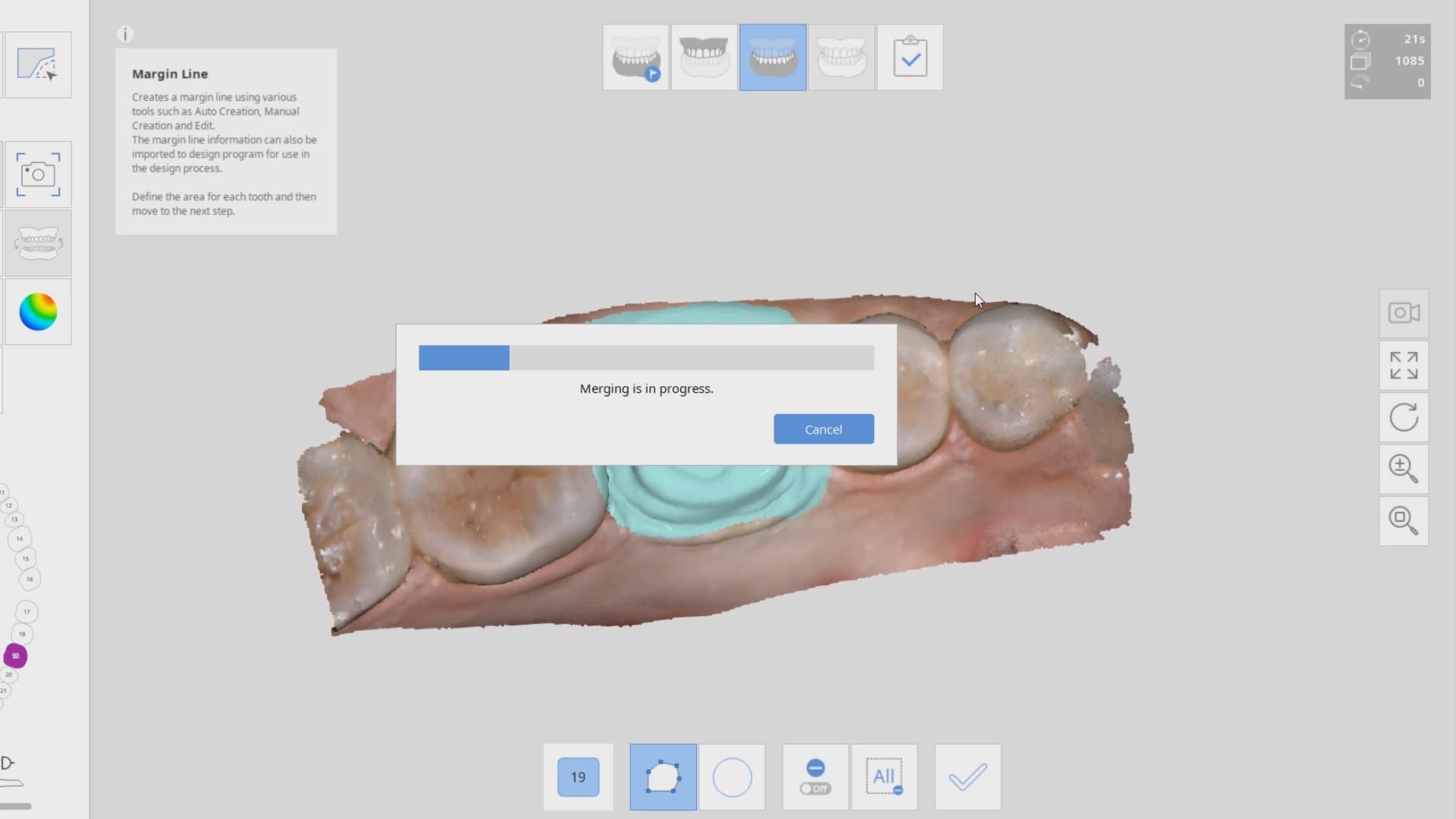

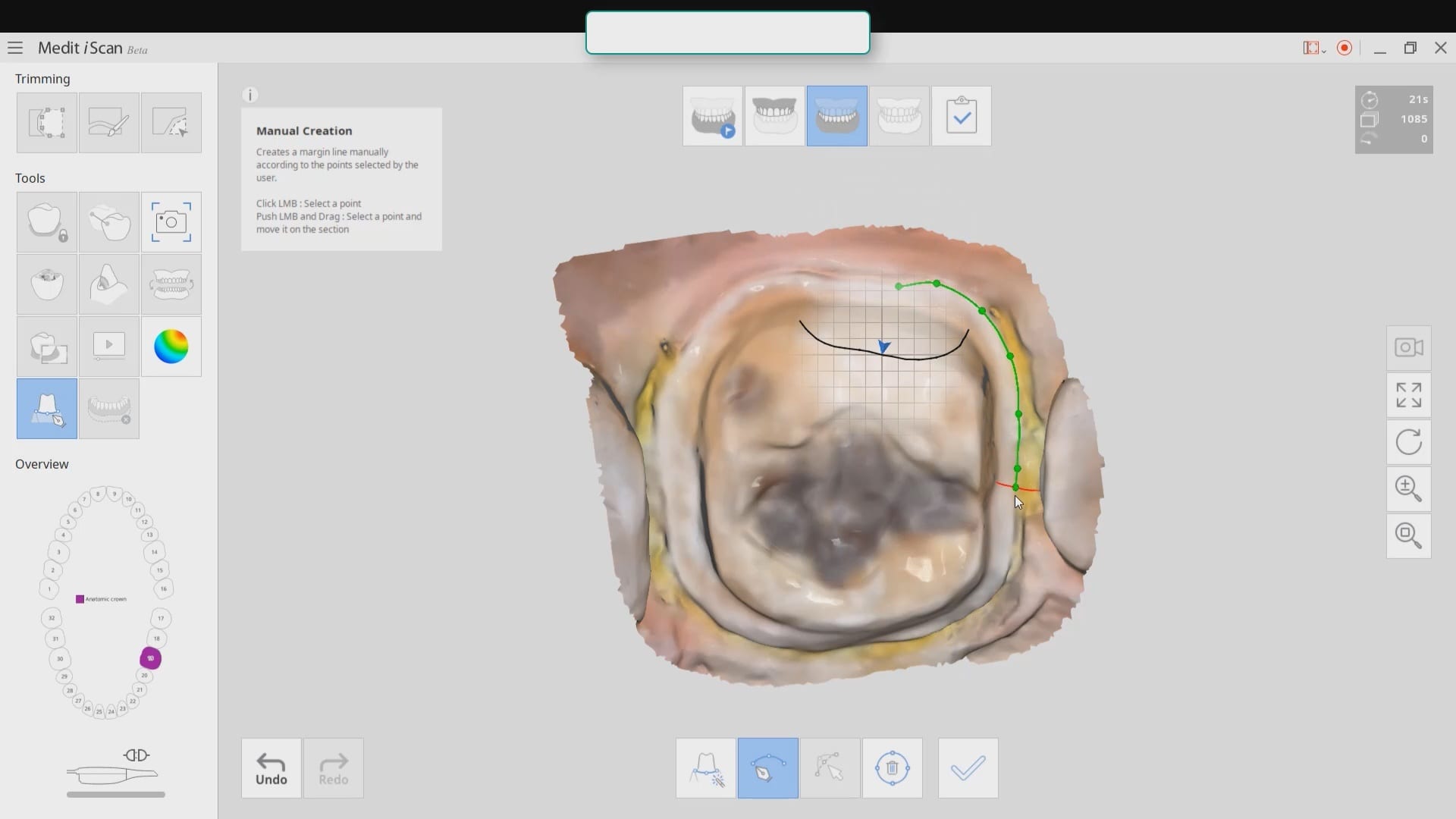

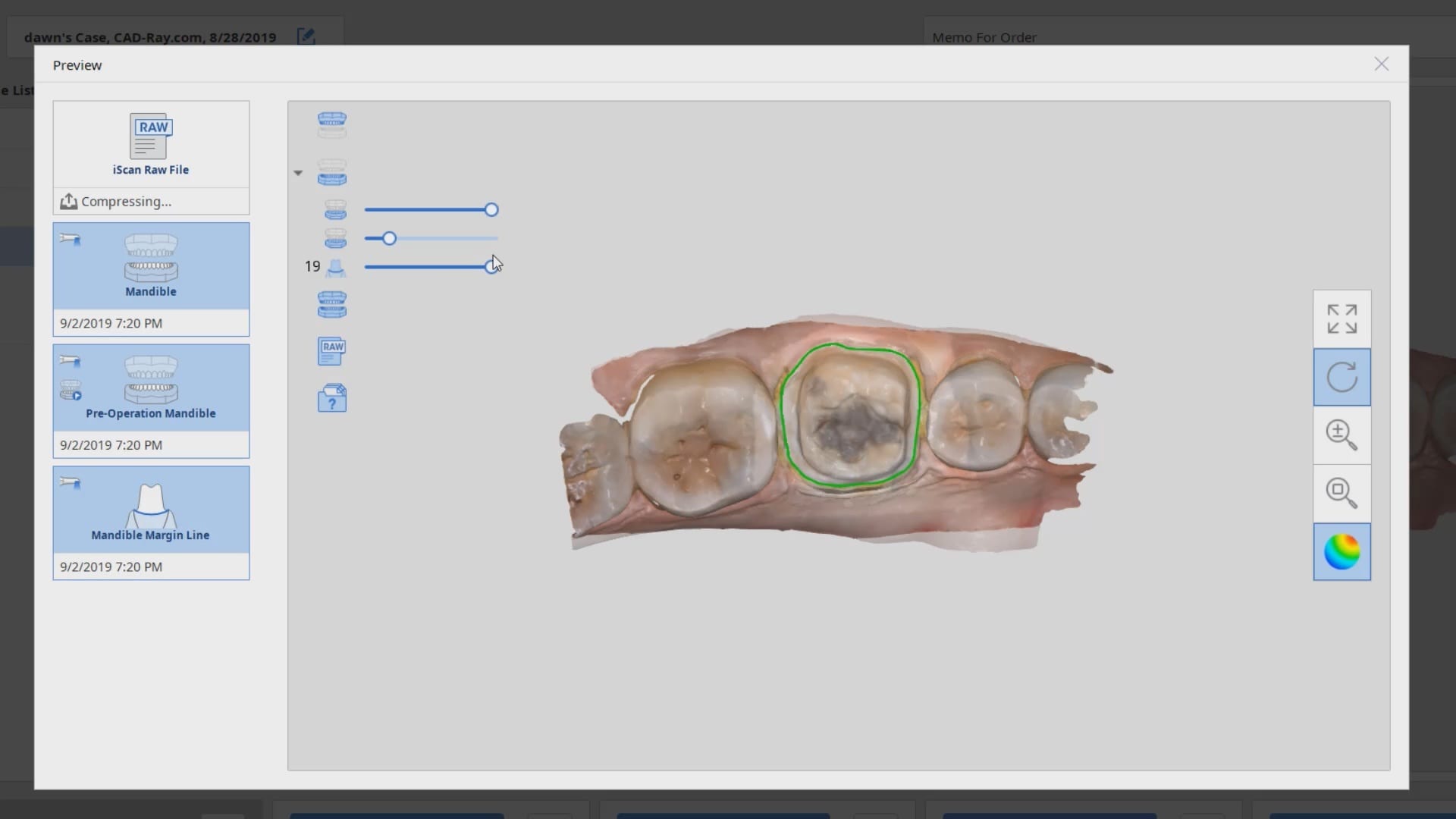

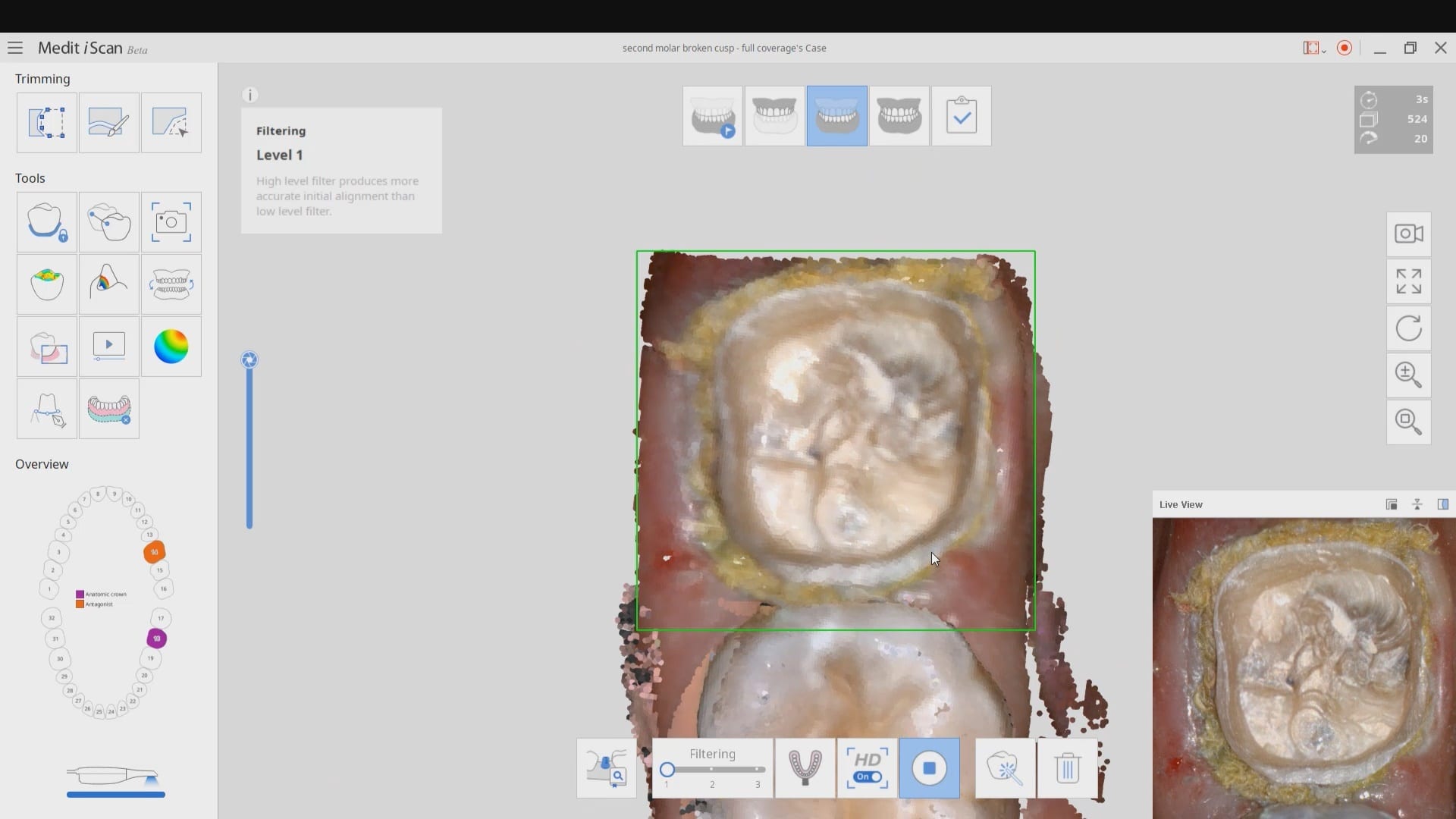

On September 5, 2019 Medit will officially launch the 2.1 software that will allow dentists to mark their own margins before sending to the lab. Since most images captured from models are inherently large in file size, you can selectively focus on the area where the raw images are taken. You highlight the area and you process the data sets as shown in the first video.

Once the area is identified, you can utilize the margin marking tool. You have many aids to help with margins, including the ability to visualize the transition from one plane to another, along with colors in the models.

In this preview, you can see which models were rendered: the lower pre-op, the lower prepped arch, and the coordinates of the margin line.

Once you have captured this detail you can click on the cad software and continue with design or submit it to your lab so they can proceed with the design and fabrication.

Click On Image to Download The Case And Import Into Exocad

In this article, we demonstrate how to manage a crown replacement on a second upper premolar with the Medit i500, exocad, and the imes icore CORiTEC ONE milling machine. The pre-existing crown was over 2 decades old and the recession revealed a supra-gingival margin. Furthermore, there was no room to improve the anatomy or its outline form as it was in occlusion with the opposing dentition.

A powerful design technique is the copy of the pre-existing crown. Images of the pre-op are taken while the patient is numb and its contours are copied onto the final design of the restoration. This process usually takes a minute or so, after which we milled a size 12 emax block restoration.

One of the most dreaded procedures in dentistry is to cut off a bonded lithium disilicate material. With zirconia, since the bond strength is weak, just “rattling” the crown helps it pop off. You could also debond the restoration with a laser pretty quickly. With emax, you must use copious amounts of water so you don’t fry the pulp. You must also refrain from splitting the crown with a crown remover because you can damage the remaining tooth structure catastrophically.

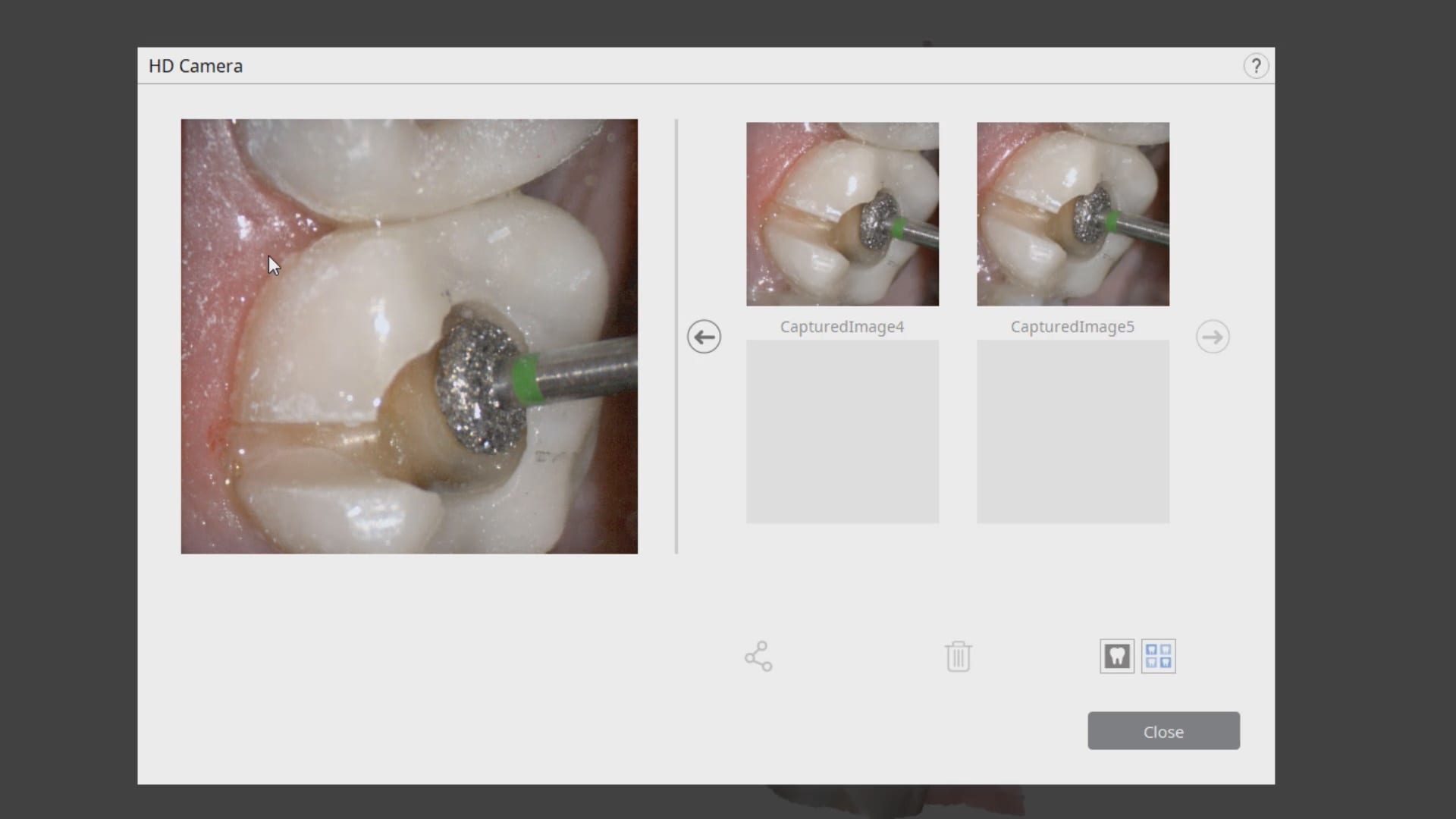

In this sequence of photos, you will see how we recommend the removal of the bonded restoration. You must first create a trough across the occlusal surface of the crown. Ideally, use a 1.6 mm disposable bur to reach the interface between tooth structure and restorative material. As soon as you reach this junction, take a flat ended diamond bur and start working that same location and remove all the ceramic on the occlusal surface. Staying right at the junction of the material and tooth is the critical part of the process.

After you have removed the occlusal surface, you can take any bur and work the junction one the axial wall. By this time enough work has been done where the walls of the restoration start to break and peel off on their own.

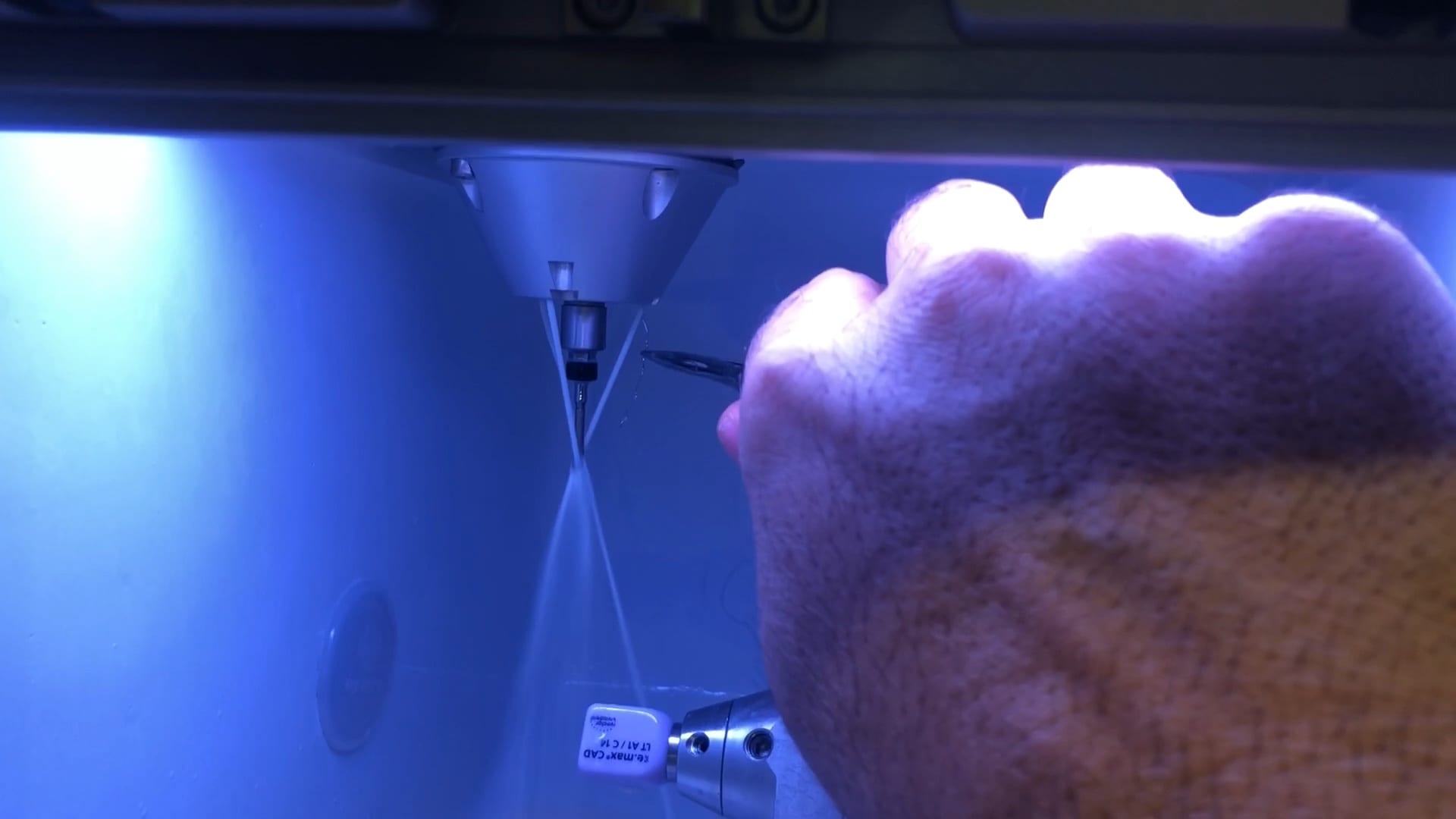

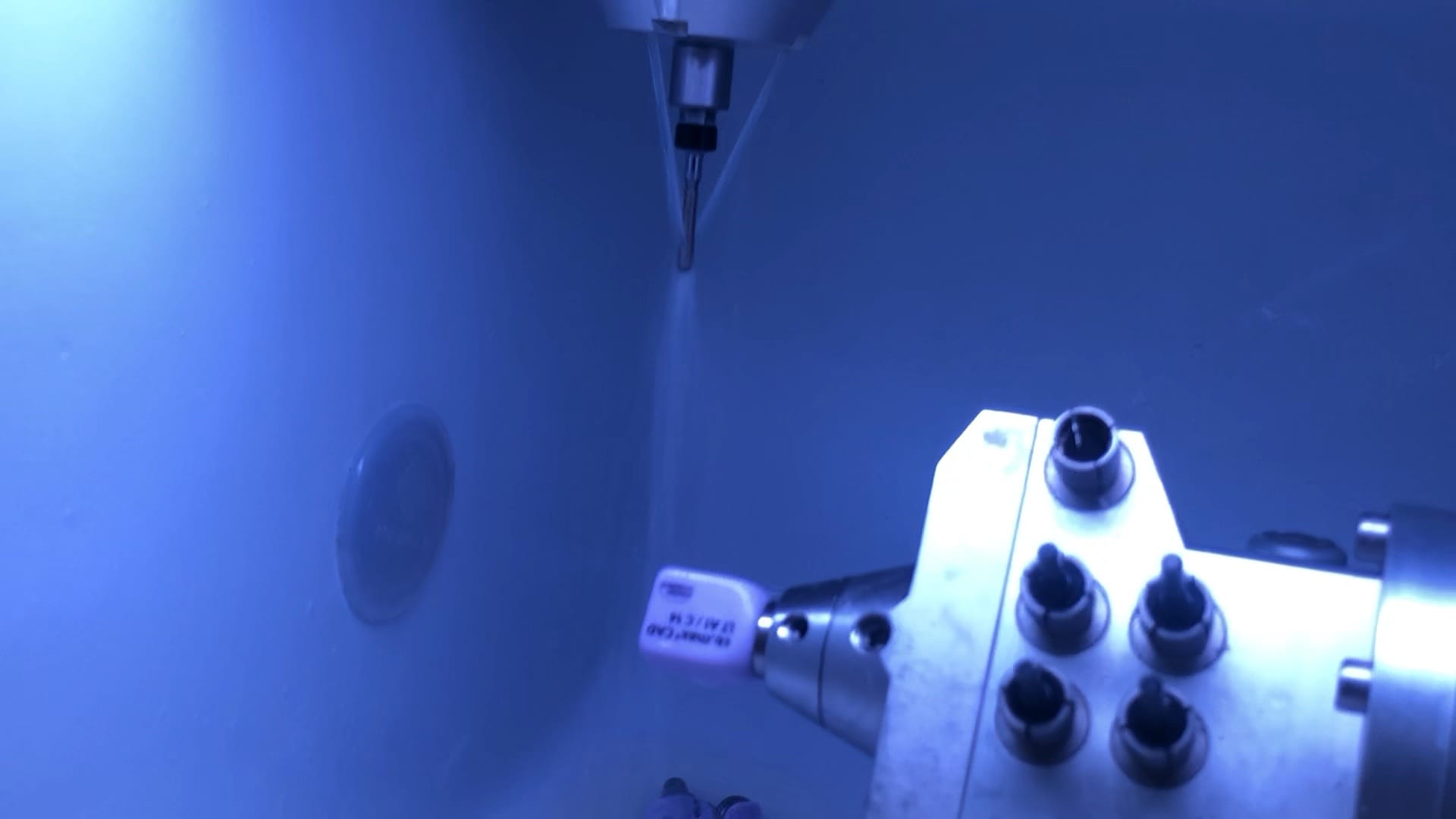

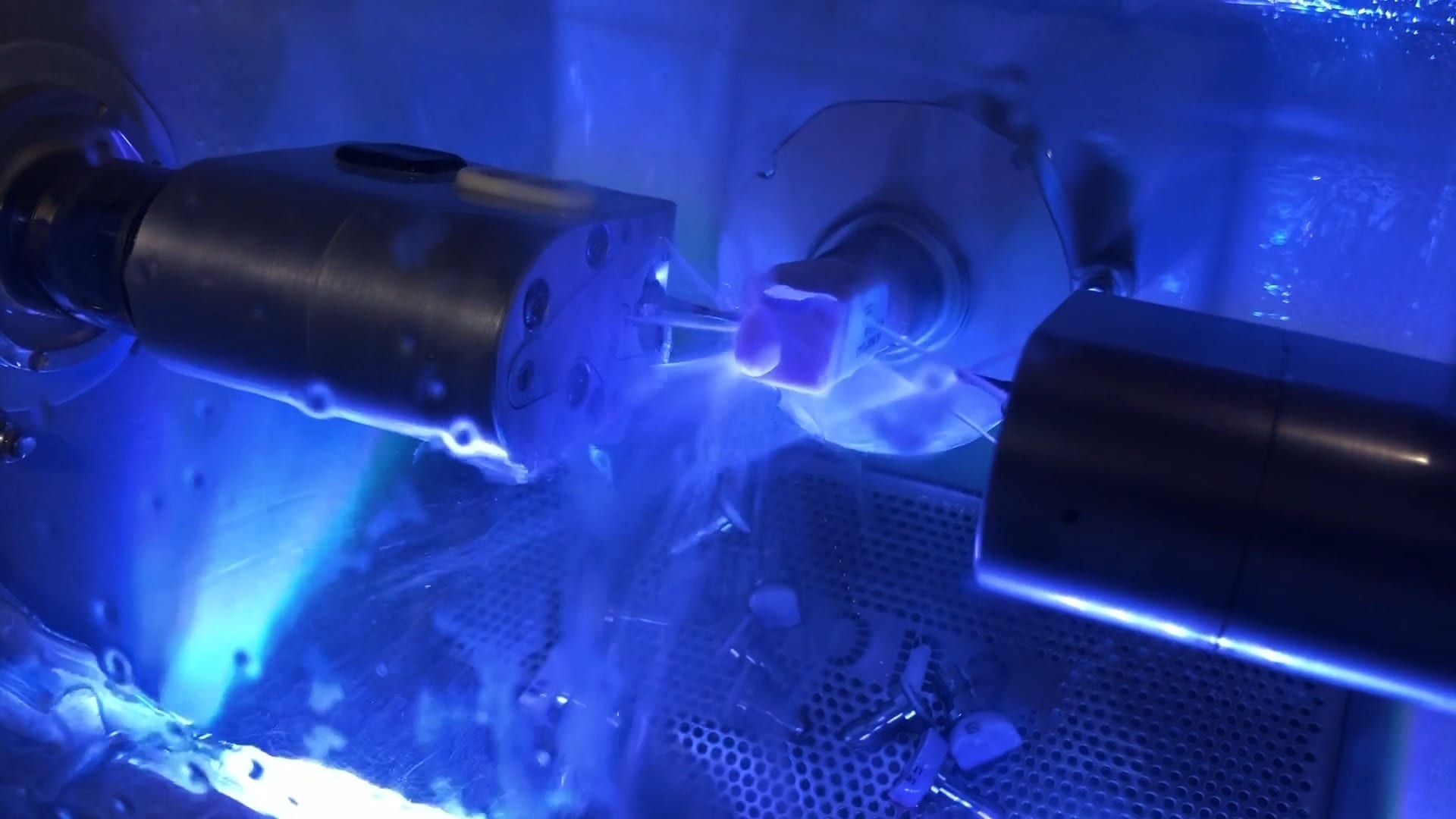

All milling machines have guidelines for proper cleaning and maintanance. The imes icore CORITEC ONE’s spray channels must be kept clean, otherwise they will spray off the target block materials. Essentially you will dry mill ceramic which will damage the material and break the drills very quickly.

You can see how little particles of ceramic and titanium dust can clog the lines.

Here we just used an ortho plier and orthowires to unclog the lines. It’s easiest to have the water spraying so you can identify the channels and see the immediate results.

When cleaned and clear make sure the water it sprayed on tip of the drill from all channels.

In this particular case, we are restoring a lower left molar with a full coverage crown. The pre-existing condition has multiple fracture lines and the patient currently wears a retainer. The pre-op optical impression is taken while the patient is reaching anesthesia. Once enough reduction has been achieved, the preparation is captured and an immediate proposal is rendered that replicates the pre-op condition perfectly.

Note how the settings for the start of the adhesive gap influence the cement line that you see on the post-op bitewing after immediate delivery, even though it was milled with the CEREC MCXL.

copy mode- instant proposal

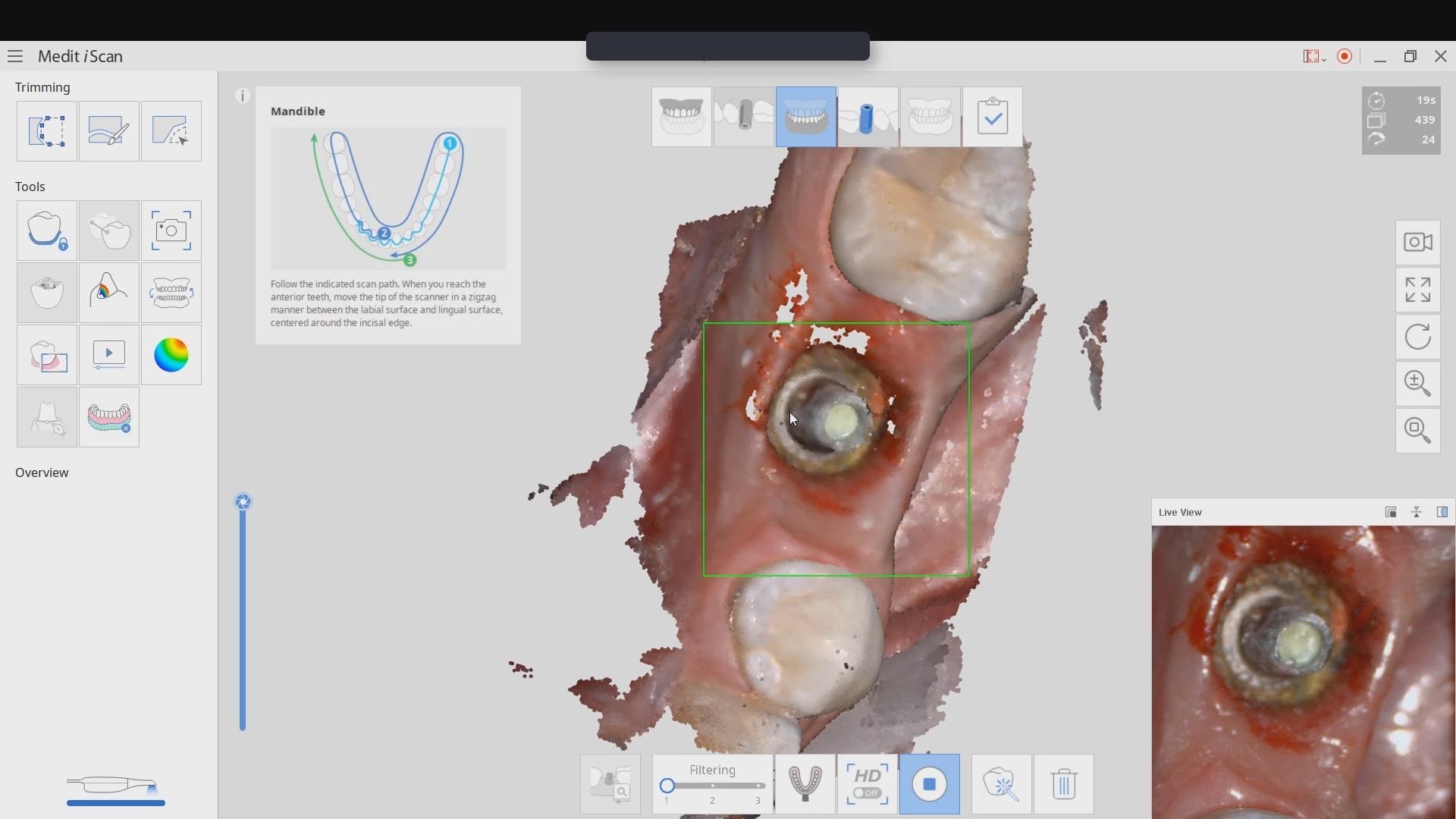

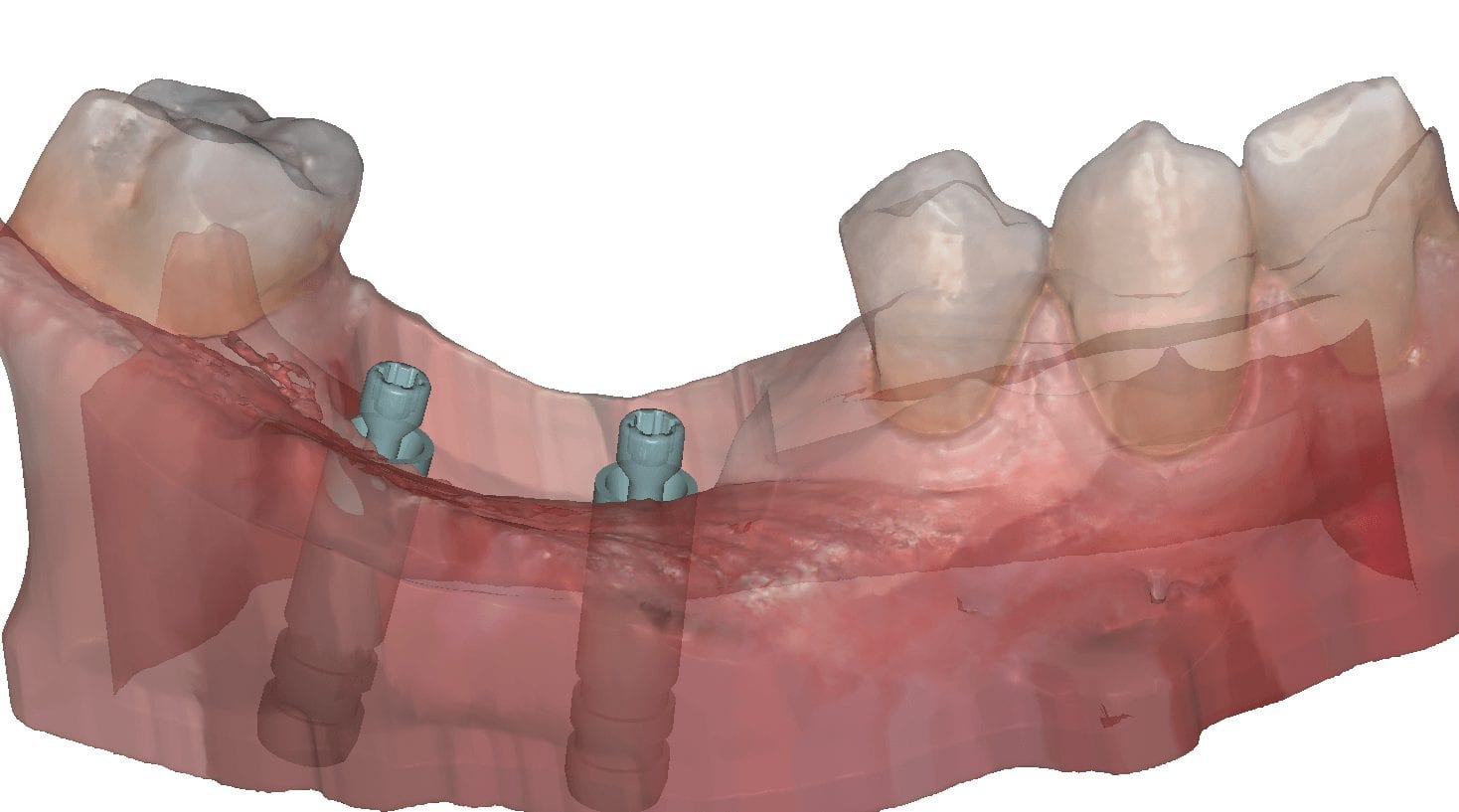

A new feature coming to Medit i500 is the automatic detection of scanbodies while you are imaging. In this clinical case, two implants are placed in the lower left quadrant in a fully guided fashion. Spacing limitations and proximity to vital anatomy did not allow for proper parallelism. This can create all kinds of headaches with analog dentistry where the trays can inadvertently lock in the mouth of distort upon poor up.

With the digital approach, you can scan the gingiva, the arch with easy access to adjacent contacts, and then the scanbodies themselves. What is great is that you do not disturb the primary stability you just achieved by placing physical forces on freshly placed implants.

Once the images are captured and the scanbodies are identified, we launch exocad and the data is not only automatically imported into the Computer Aided Design Software, it also plots the fixtures in the correct position and identifies their location and timing so you can proceed with the design of the custom abutment and / or tibase restoration.

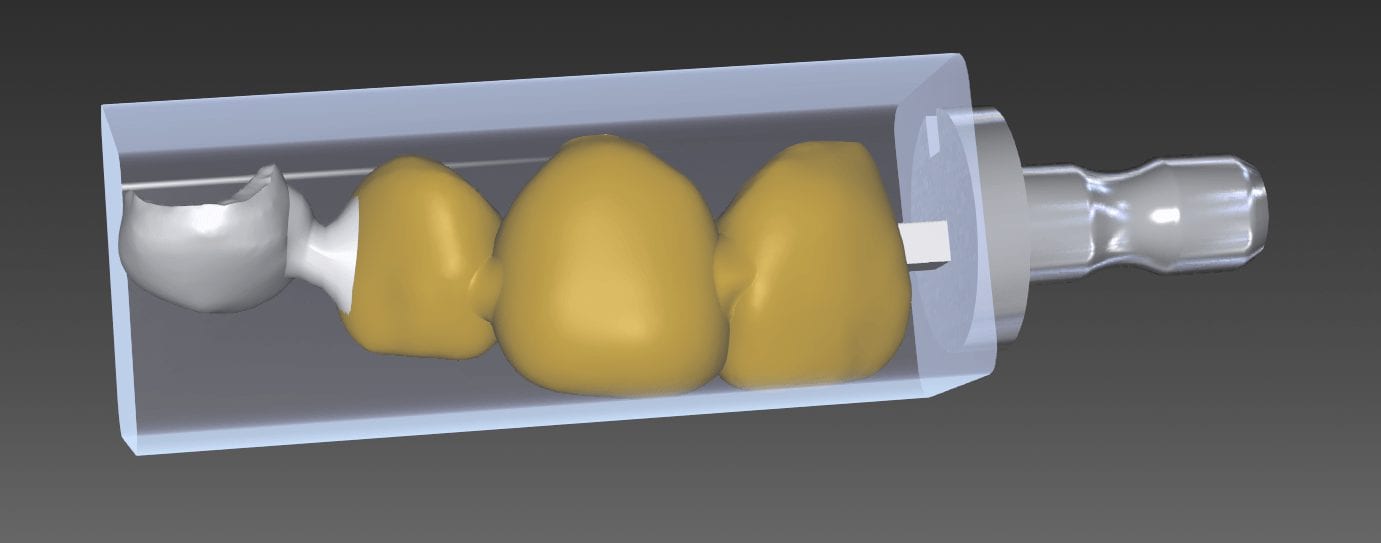

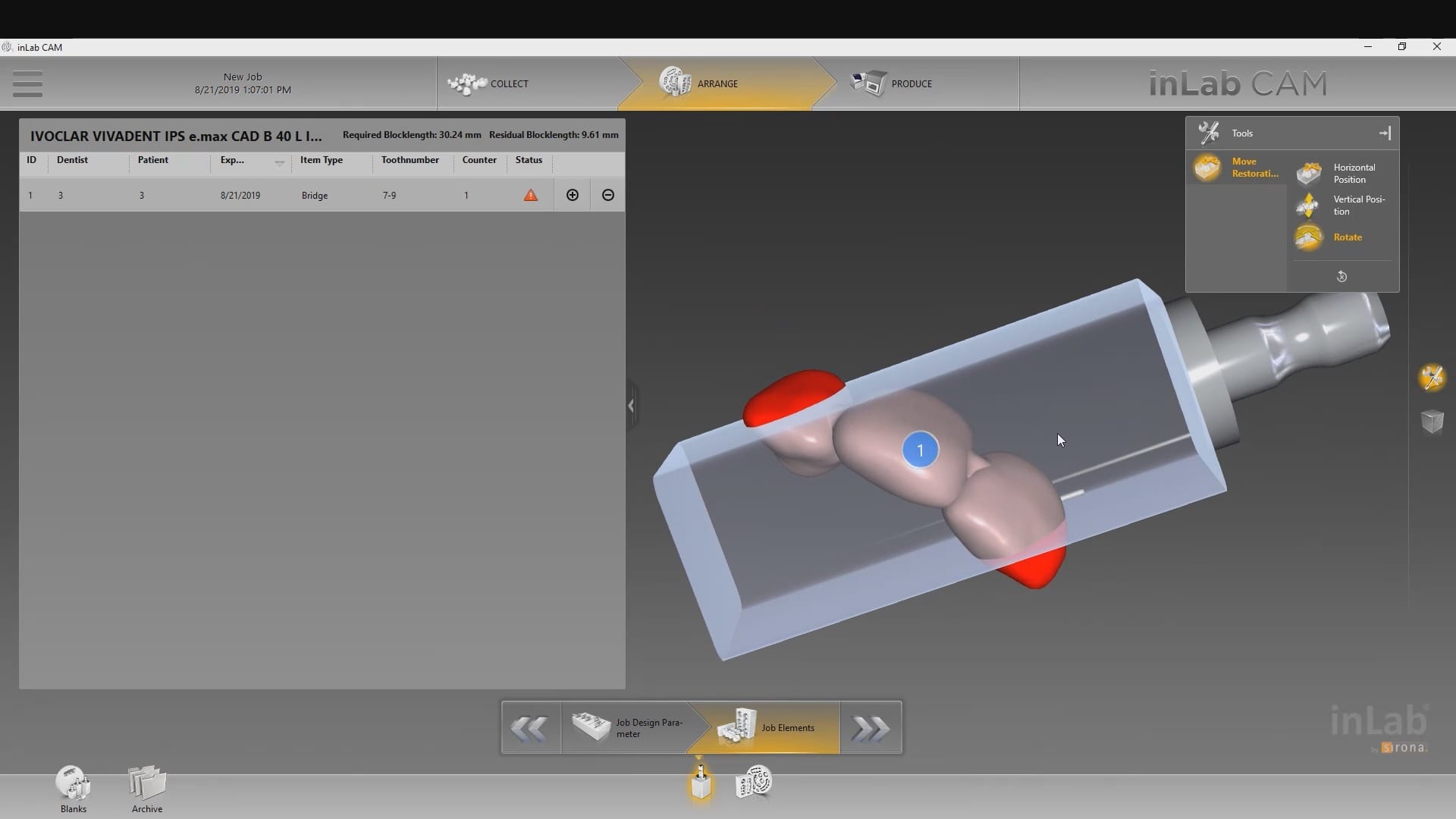

This 4 unit case was imaged in Medit i500 and designed in exocad. The final restoration was taken to CEREC inlab cam. When the construction file is imported into cam, it contains data such as the margin line which is important for the milling machine to know for its tool path calculations.

In this particular situation, the construction file dictated the position of the restoration in the block which would have not allowed for proper milling. Instead of loading the construction file, we imported the stl design, redrew the margins really quickly and were able to mill the two separate (4 unit) case out of a single emax block.

The milled restorations were then separated and finished free-hand

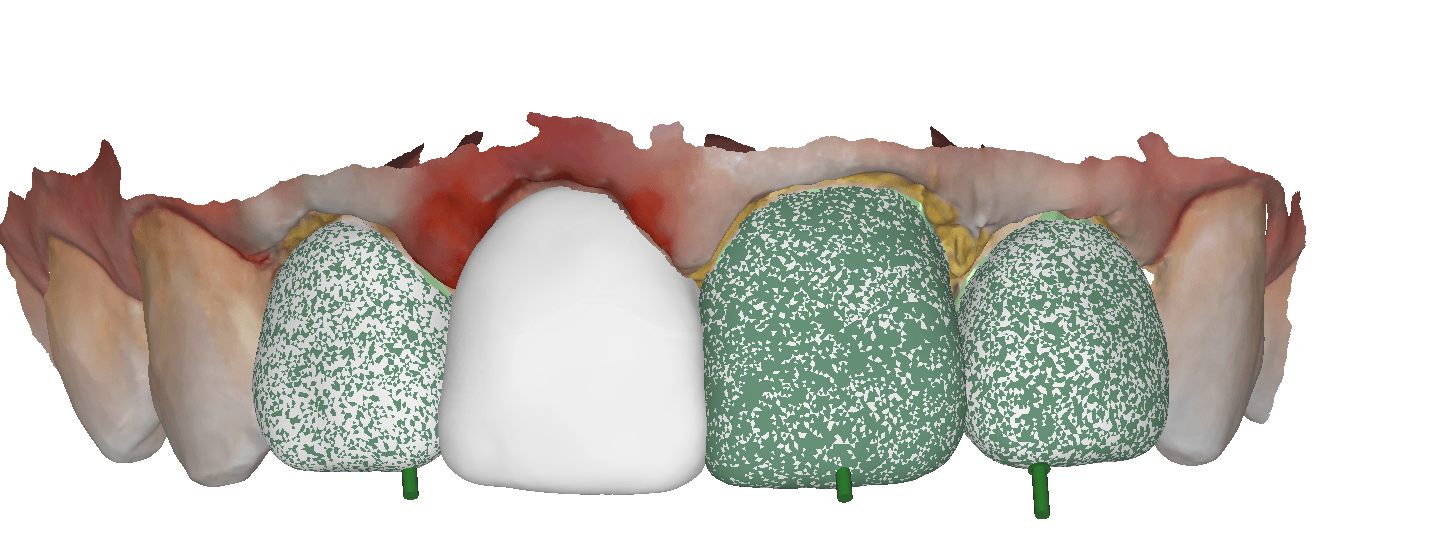

try in and deliver of 3 unit bridge and single unit veneer after extraction of right central incisor

try in and delivery of a 3 unit bridge and a single unit veneer

Same visit crowns can be a practice builder. We had a patient referred for in house fabrication of a restoration because she did not want to go through the procedure twice. A family member made the referral for a broken tooth.

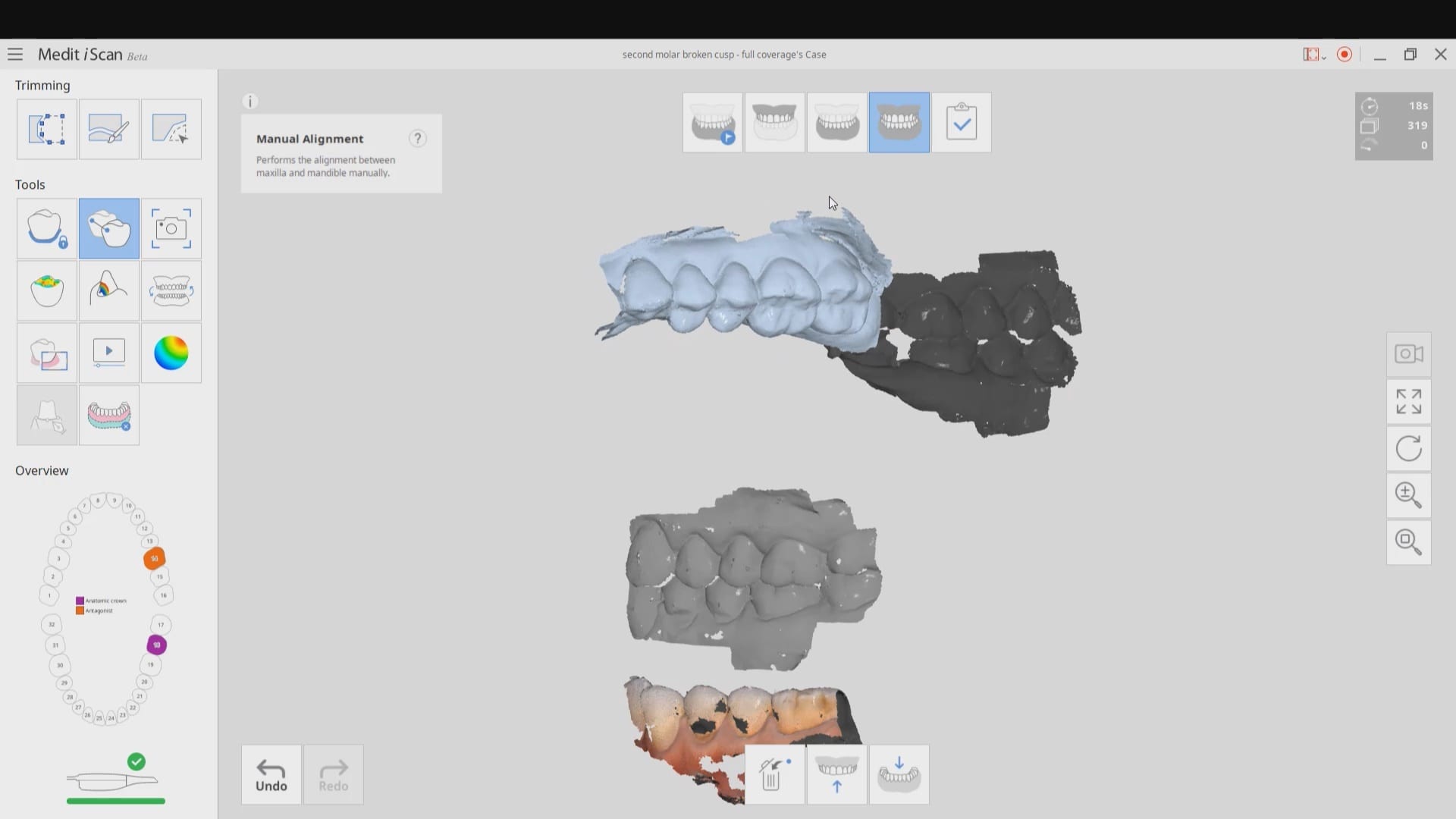

After the tooth tested vital and the patient consented to treatment, she was anesthetized. While waiting for the onsite of anesthesia, the upper arch was imaged along with the lower arch and the bite in the occlusal one window box. The case was set up for just imaging the preparation. Most of this can be delegated to team members.

We highly recommend that you capture the final bite after you have finished preparing the most distal tooth. You can use your camera to visualize your clearance. You can keep reducing the occlusal surface until you have enough clearance.

In this particular case, when we took the second occlusion images, the models would not turn green. When this happens, you should immediately ascertain if you have captured the first or second bite correctly. Double check to see if the jaw settled or if the patient moved their jaw during this acquisition step.

You can watch how we troubleshoot the bite and manually choose the second bite to relate the arches together.

Once the bite is captured, the isolite is re-inserted and the tissue is displaced and isolation is achieved. Then the predation is captured.

After the crown is seated a final bitewing is taken to verify seat and if any excess resin is left behind.

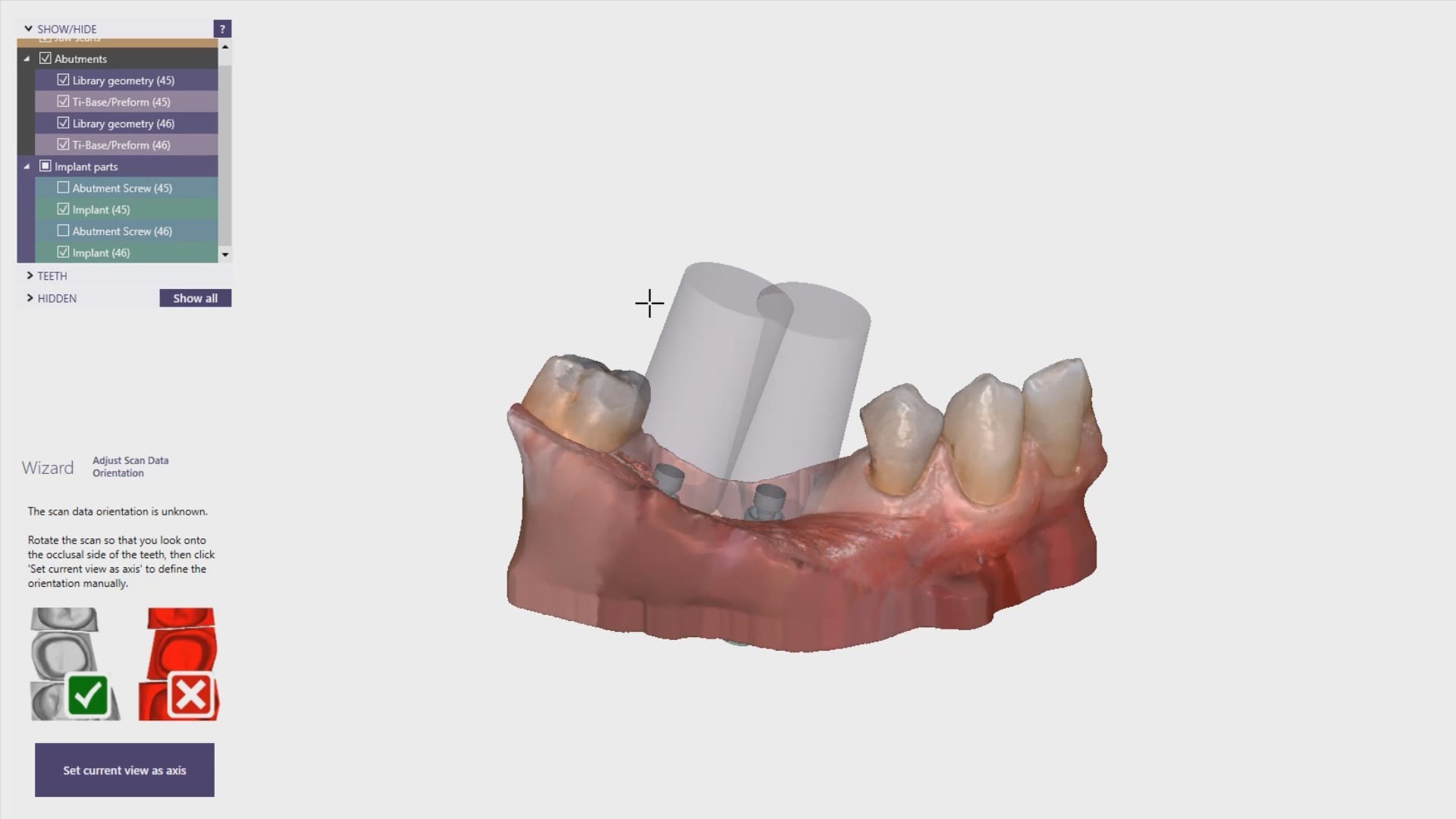

At CAD-Ray we are constantly testing milling machines that can render ceramic or metal abutment restorations. In this particular case, we are testing the conelog line of tibases and utilizing the automated identification of the scanbody with the new Medit i500 V2.1 Artificial Intelligence program. Not only does the software identify the scanbody and locate the fixture but it also imports the whole complex into the cad software where the fixture and digital tibase are already identified and aligned.

We scanned the tibase as well on the model and merged it to the digital proposal to see how closely the digital proposals matched the physical model.

It is very important to properly identify the scanbodies and to label them accordingly. A single mis-step can result in ill fitting restorations and cause disappointment. If the nomenclature or the math doesn’t add up, it is always a good idea to contact the manufacturer of the scanbody to verify your findings.

In the first set of videos, we demonstrate how the scanbody is imaged with the Medit i500. For this particular demonstration, we placed a tibase on a conelog 4.3 mm diameter fixture and then a peek scanbody on top of it. Indexing and making sure it is seated is of paramount importance. Once the software identifies the complex it can automatically import it into exocad software so you can proceed with the design.

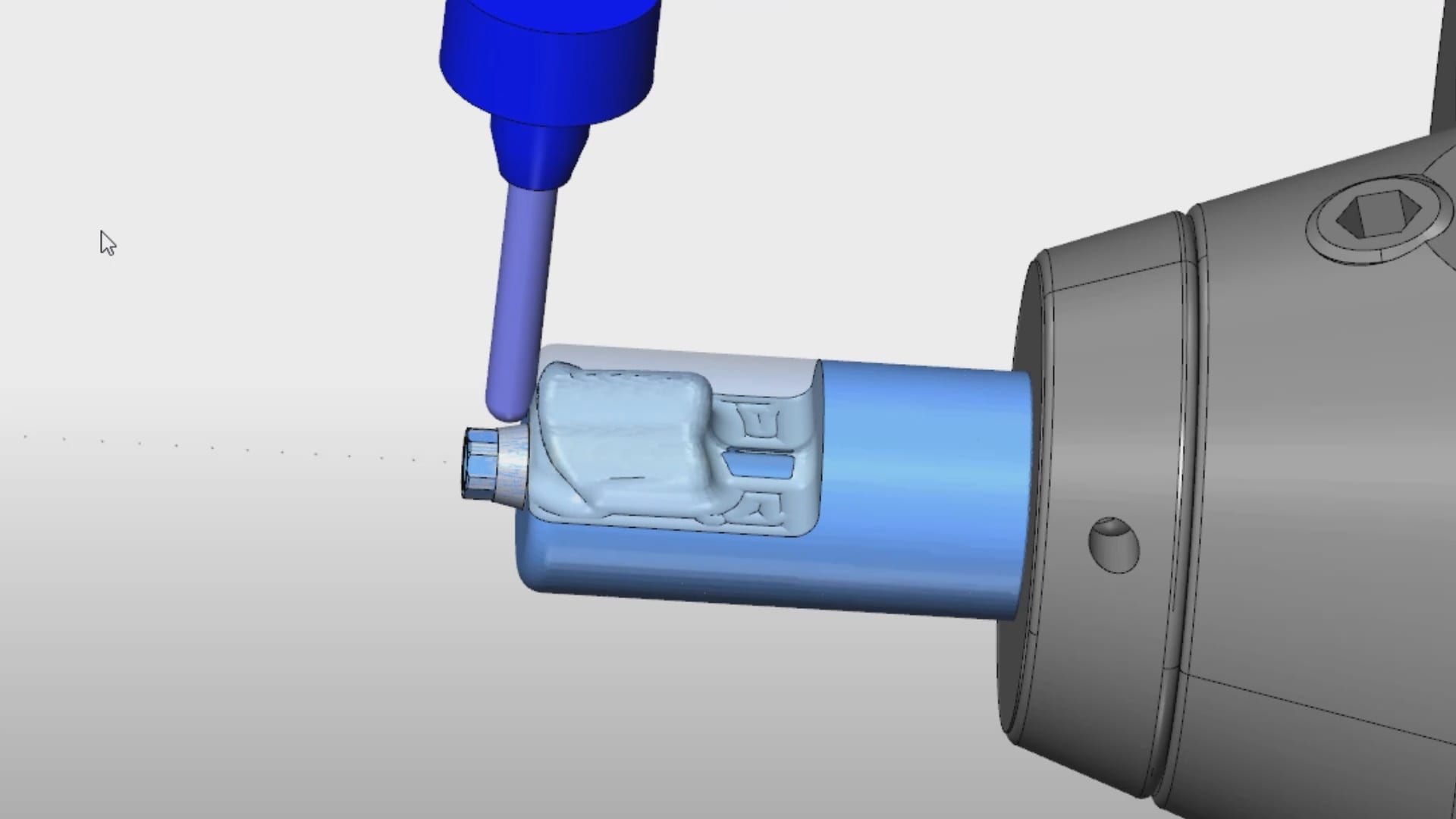

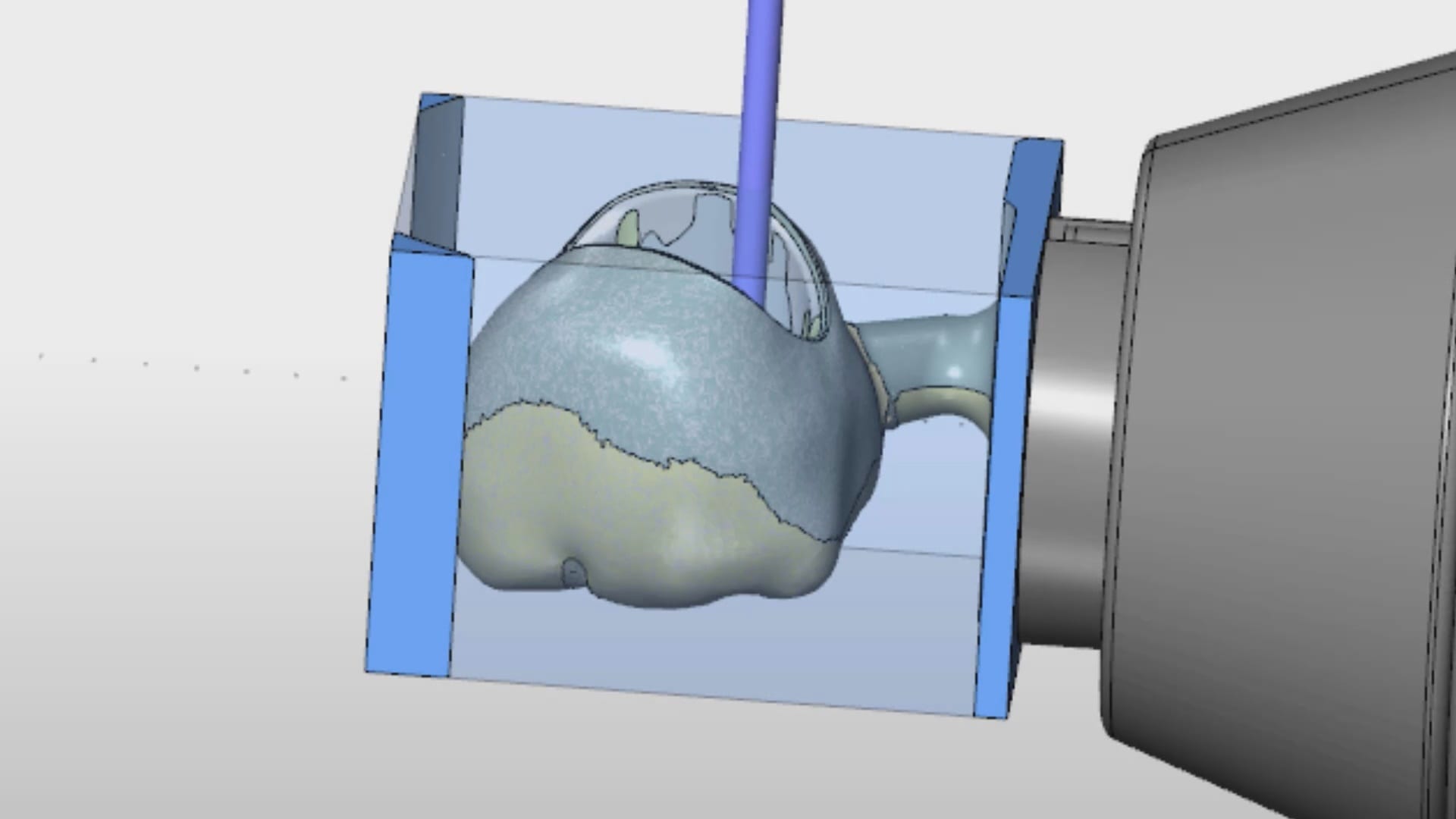

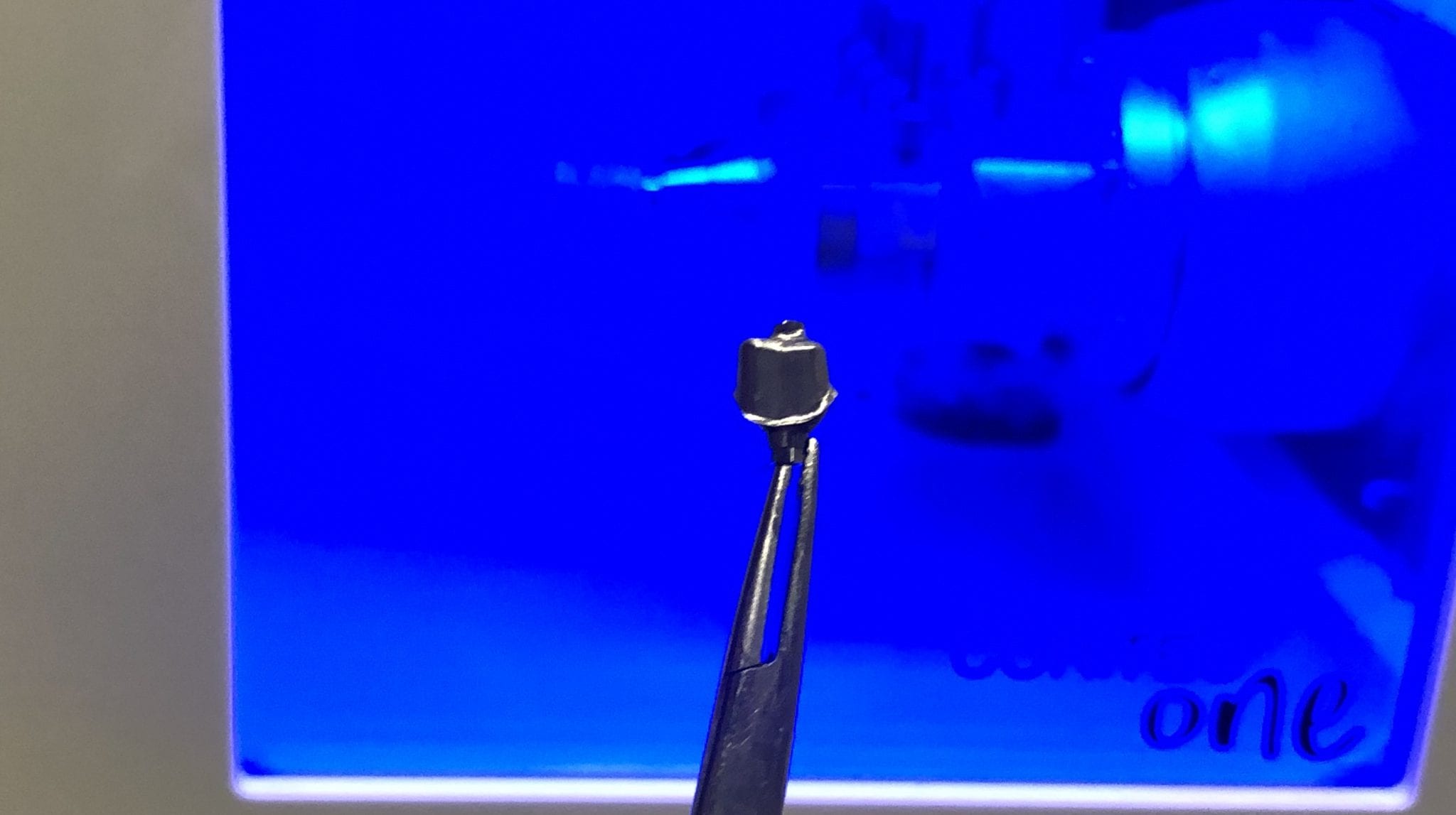

This test case is milled for record keeping and FDA compliance as we are distributors of multiple scanners and milling machines. We are only concerned about the fit of the restoration. After the design was completed it was then imported into milbox CAM software, nested, and the sprue was configured for the mill.

The first produced restoration did not seat completely and the internal was relieved in an analog manner. It did finally seat but by then, it lost its anti-rotation mechanism. The case was then reloaded in millbox and the internal relief was increased by – 0.05 mm. That simple adjustment allowed for proper seating without any analog adjustments. You can also appreciate some residual material that may keep you from seating. Both the software and the carbon marks left on the intaglio of the restoration can be clear indications of what needs to be adjusted.

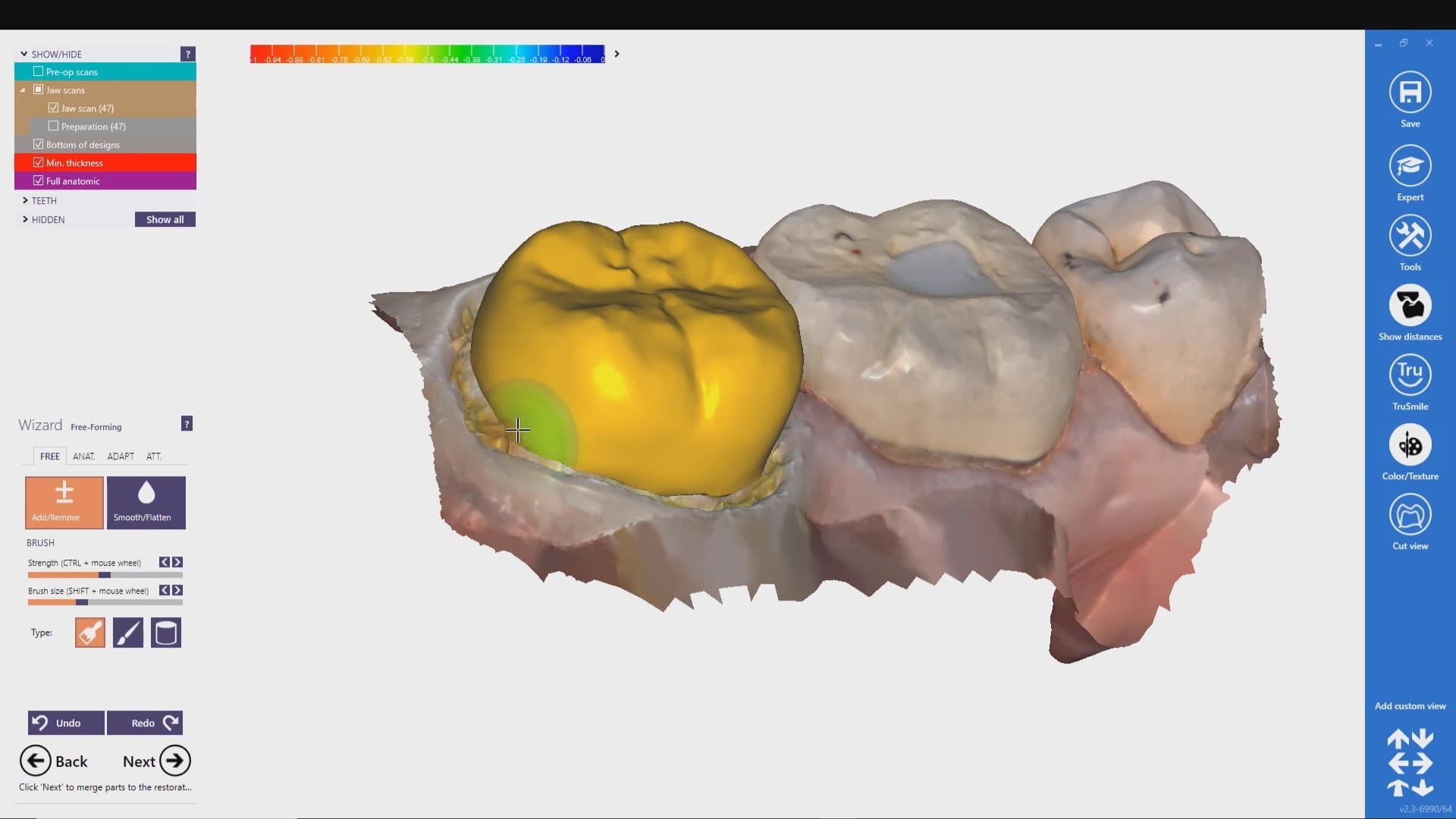

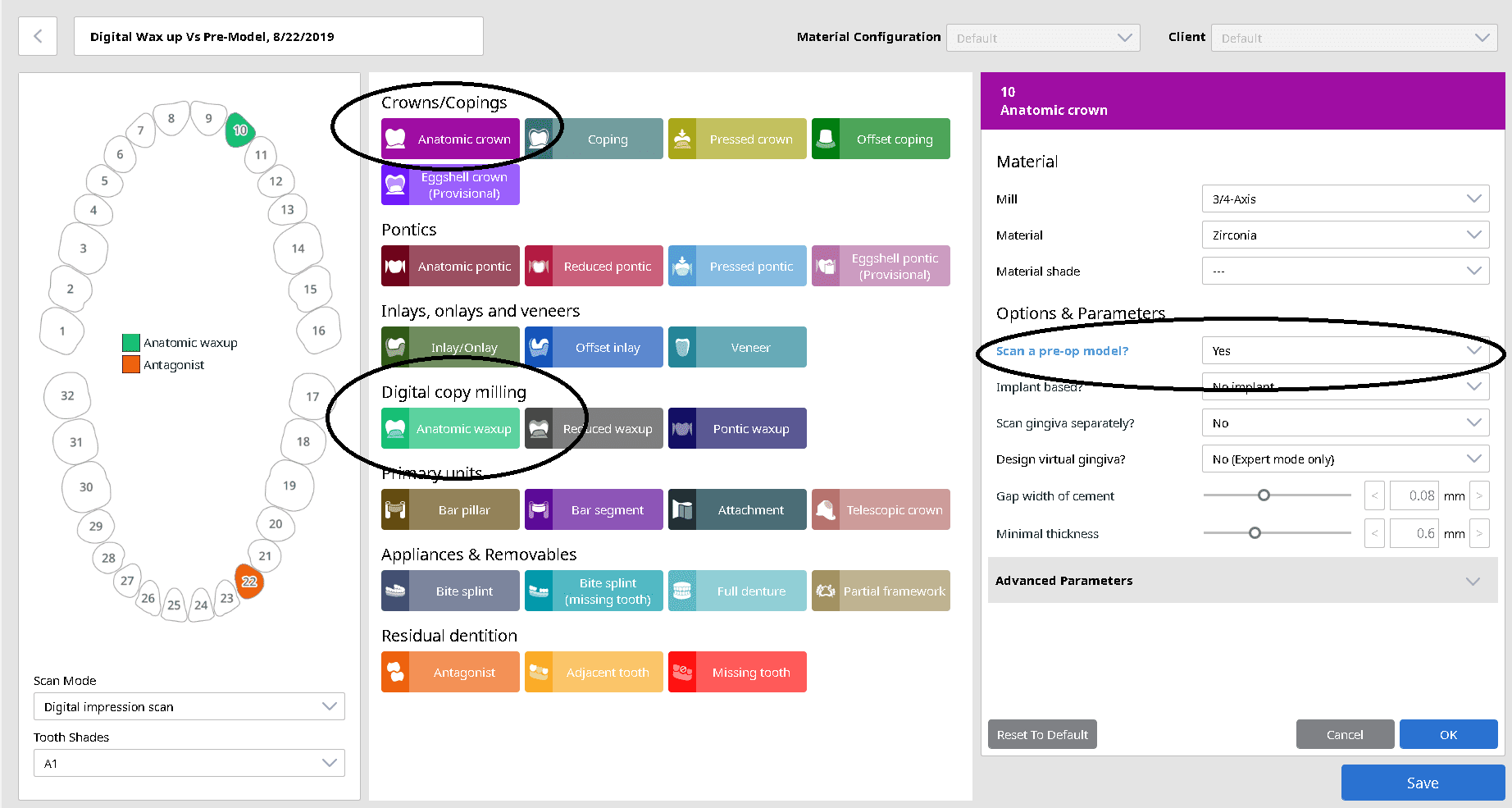

In CAD-Ray’s version of exocad, we have dramatically reduced the steps necessary to get a final proposal with copying a pre-op, mock up, or wax-up. We’ve configured the wizzard to walk you through the steps of defining your path of draw after margin placement, trimming away material you don’t want your proposal “to touch” and giving instant proposals.

There is one difference you need to be aware of in design modes; Anatomic Crown vs. Anatomic Wax up. When designing a crown, you can choose to include the pre-existing model in the equation. When you select “YES” to “Scan Pre-Op Model?” you tell the design software to incorporate that into the equation, but you will get a free form proposal and then you adapt it to the pre-op model. Alternatively you can choose Anantomic Wax Up and you will design an restoration in under a minute that is to your liking.

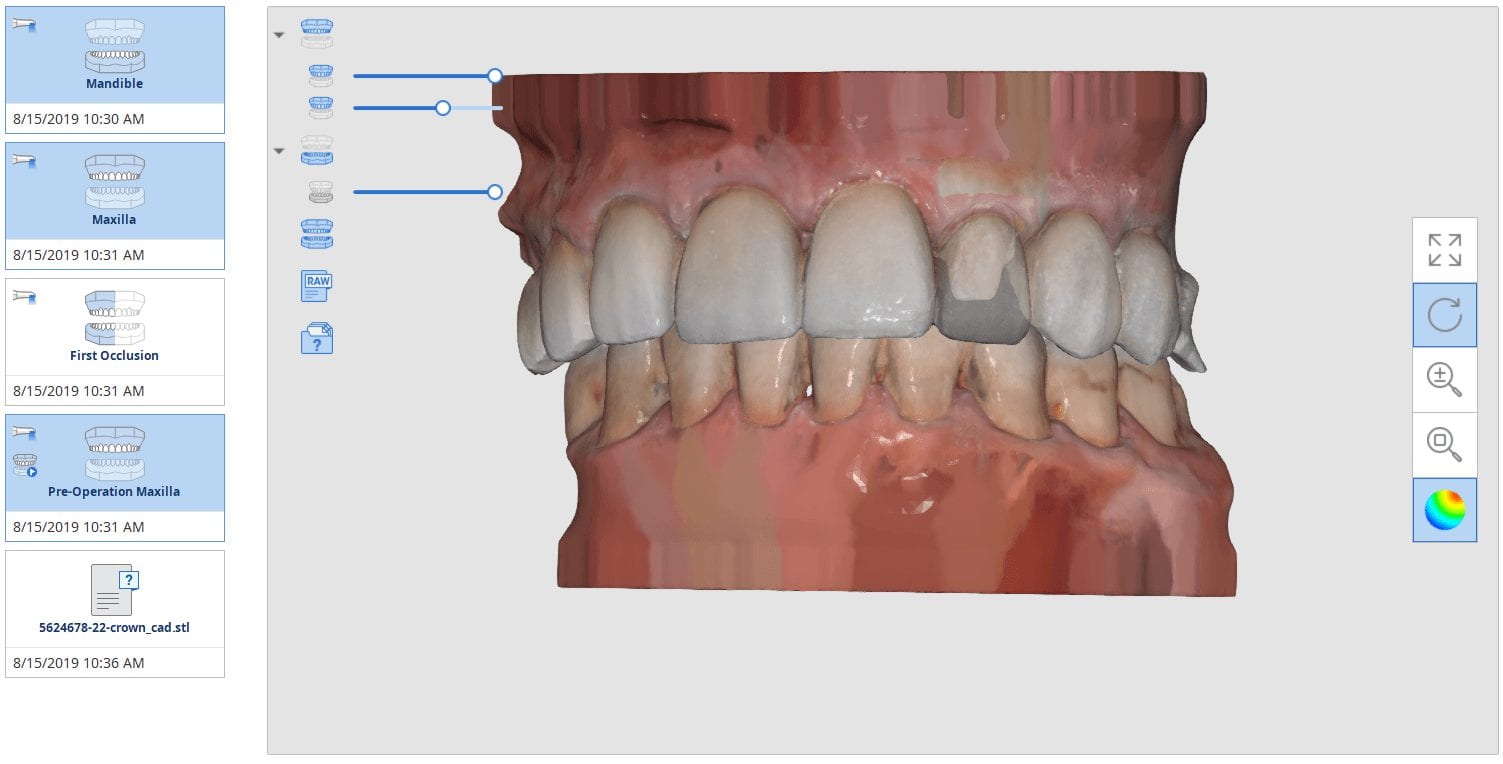

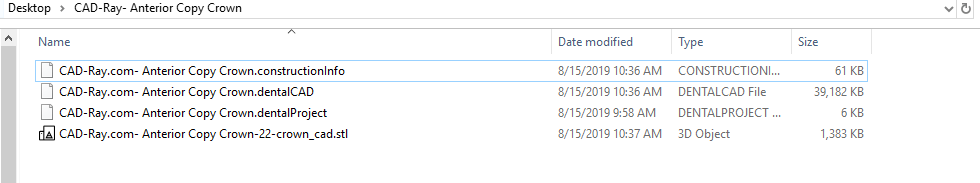

In this article, we feature an upper left lateral crown that needed to be replaced due to recurrent decay. While the patient was getting numb, we defined the job description in the Medit i500 software and imaged the pre-existing crown, the opposing and the bite. We digitally cropped out the tooth to be prepared and proceeded with crown removal. Once the margins were refined and the tissue was displaced, we imaged the preparation in HD mode and processed the case.

Once the digital models were rendered, we launched the integrated CAD software that automatically imported the pre-op, the opposing, the prep model, and the bite. Their relationship is preserved in the CAD software and no modifications were necessary. You have two ways to copy the pre-op; one way is to program the CAD software so it replicates the pre-op perfectly while the other gives you a raw proposal that you can then choose to adapt to pre-existing situation.

Once the case is designed in the CAD software, you can then take it to any CAM and Milling Machine to produce a restoration. Here we milled an emax restoration with the CEREC MCXL and the imes icore CORiTEC ONE at the same time so we can compare the final results. The CEREC milling machine produced a restoration faster by about 90 seconds but the final results of the margins by the CORiTEC Machine was far superior. Also, the CAM software, Millbox in this situation, allows us to choose a third drill that is 0.6 mm in diameter. This increases milling time but results in less overmilling than the 1.2 mm burrs that milll the intaglio of the CEREC Machine.

Immediate post op

You must be logged in to post a comment.